Introduction

In controlled environments, maintaining cleanliness is paramount. Cleanroom Sticky Mat plays a crucial role in preventing contaminants from entering sensitive areas. This guide will help you understand how to select the appropriate sticky mat for your specific industry needs.

What is a Cleanroom Sticky Mat?

A Cleanroom Sticky Mat is a multi-layered adhesive mat placed at the entrance of cleanrooms. Its primary function is to capture dust, dirt, and other particles from footwear and equipment wheels, ensuring that these contaminants do not enter the controlled environment. Each layer can be peeled off to reveal a fresh adhesive surface, maintaining optimal cleanliness.

Key Features to Consider

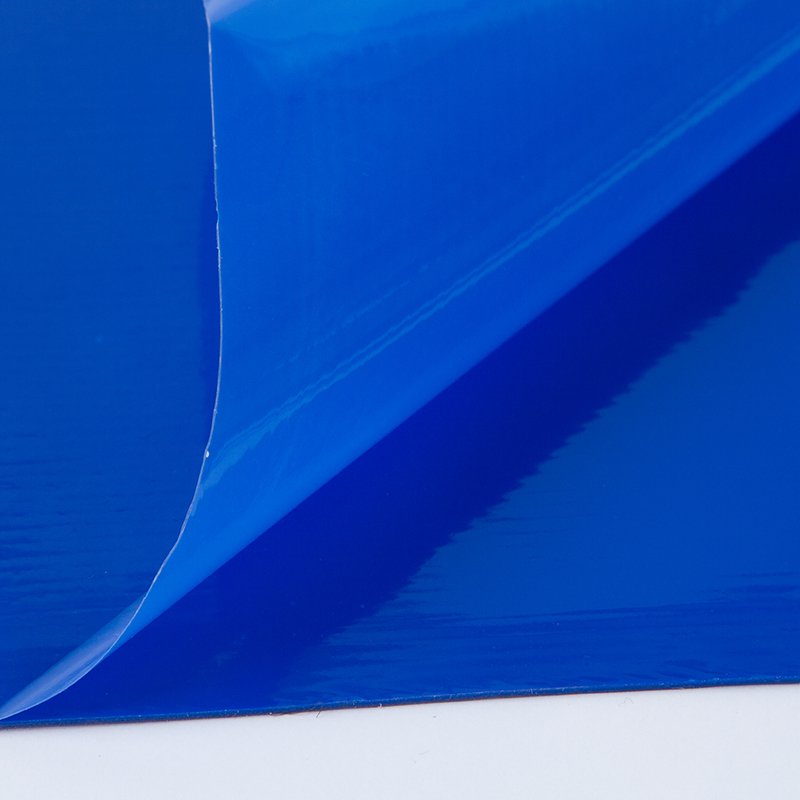

1. Number of LayersSticky mats typically come with 30 or 60 layers. More layers mean fewer replacements, which is beneficial for high-traffic areas. 2. Adhesive StrengthThe tackiness of the mat determines its effectiveness in capturing particles. High-tack mats are suitable for environments with stringent cleanliness requirements, while medium-tack mats are ideal for general use. 3. Antimicrobial PropertiesSome mats incorporate antimicrobial agents to neutralize bacteria and fungi, providing an added layer of protection in sterile environments. 4. Color OptionsCommon colors include blue, white, and gray. White mats are preferred in ultra-clean areas as they make it easier to spot contaminants. Blue and gray mats are often used in less critical zones. 5. Size and PlacementMats come in various sizes to accommodate different entryways and traffic volumes. It’s essential to choose a size that ensures complete foot or wheel contact to maximize contaminant removal.

Industry-Specific Recommendations

1. Pharmaceutical and BiotechnologyIn these industries, maintaining a sterile environment is critical. Opt for mats with antimicrobial properties and high tackiness to ensure maximum particle and microbial capture. White mats are recommended for easy visibility of contaminants. 2. Electronics and Semiconductor ManufacturingStatic electricity and dust can damage sensitive components. Choose ESD-safe sticky mats with appropriate tackiness to prevent static discharge and particle intrusion. 3. Healthcare FacilitiesHospitals and labs require stringent infection control. Mats with antimicrobial agents and high tackiness are ideal. Regularly replace layers to maintain effectiveness. 4. Food ProcessingPreventing contamination is vital in food production areas. Use mats with medium tackiness and antimicrobial properties. Ensure mats are placed at all entry points to processing zones. 5. Aerospace and Automotive IndustriesPrecision is key in these sectors. Select mats that effectively capture fine particles. Blue or gray mats can be used, depending on the cleanliness level required.

Placement Guidelines

- Entry Points: Place mats at all entrances to controlled areas.

- Gowning Areas: Use mats before and after gowning zones to capture particles from footwear.

- High-Traffic Zones: Consider larger mats or multiple mats in sequence in areas with heavy foot or equipment traffic.

Maintenance Tips

- Regular Layer Replacement: Change layers when visibly soiled or after a set number of entries.

- Proper Installation: Ensure mats are securely adhered to the floor to prevent movement.

- Monitoring: Keep track of remaining layers using numbered tabs.

Conclusion

Selecting the right Cleanroom Sticky Mat is essential for maintaining the integrity of controlled environments. You can ensure optimal contamination control by considering factors like adhesive strength, antimicrobial properties, and industry-specific requirements.

-5.jpg)