In semiconductor manufacturing, precision is everything. A single particle, invisible to the naked eye, can compromise an entire wafer, costing thousands of dollars in scrap and rework. As devices shrink to the 5nm and 3nm nodes, the tolerance for contamination has approached zero. This reality makes contamination control not just a compliance requirement—it is the heartbeat of yield optimization.

But here’s the question: Can something as simple as a cleanroom wiper truly make a difference in protecting multimillion-dollar wafer lots? The answer is yes, when chosen and used correctly. This article explores how contamination originates, the science behind high-performance cleanroom wipers, and why these tools are critical in boosting process yield in fabs worldwide.

Types of Cleanroom Contamination and Why They Hurt Yield

Cleanroom contamination refers to unwanted particles, residues, or electrostatic charges that enter controlled environments. For semiconductor fabs, the impact is severe: contamination directly drives defect density, reducing usable dies per wafer and eroding profitability.

The Four Critical Contamination Sources in Semiconductor Fabs:

-

Particulate Contamination: Microscopic fibers, dust, or abrasive debris—often under 1μm—can scratch wafers during CMP or cause lithography print defects. SEMI reports that 70% of yield loss stems from particle-related issues.

-

Non-Volatile Residues (NVR): Residues from cleaning agents or poor-quality wipes form thin films that disrupt photolithography, interfere with adhesion, and leave watermark-like defects on wafers.

-

Ionic Contamination: Sodium (Na⁺), chloride (Cl⁻), and potassium (K⁺) ions migrate under electric fields, causing corrosion and electrical leakage in advanced ICs. These ions often originate from water or poorly processed wipes.

-

Electrostatic Discharge (ESD): Static generated during wiping or handling can destroy sensitive circuits, creating latent or catastrophic failures.

Why It Matters: A single particle can ruin a die. A thin ionic layer can compromise an entire lot. The cost? Millions in lost yield and delayed deliveries. This is why fabs adopt stringent ISO 14644 standards and SEMI guidelines for contamination control.

How Cleanroom Wipers Break the Contamination Chain

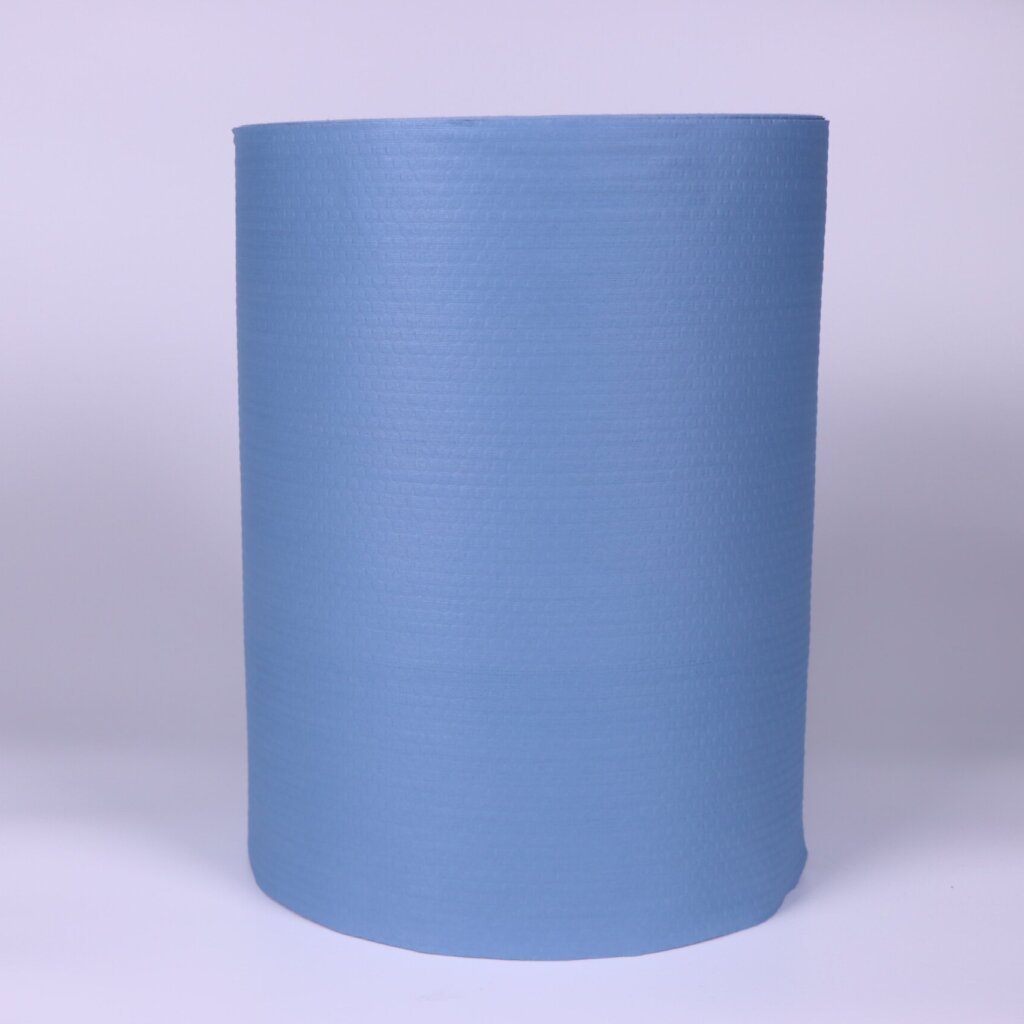

Cleanroom wipers aren’t “rags.” They are designed for particle capture, residue control, and static dissipation—all while minimizing their own contamination risk.

Key Design Features of High-Performance Cleanroom Wipers

-

Material: Continuous-filament polyester or microfiber.

-

Edge Sealing: Laser or ultrasonic-sealed edges to prevent fiber release during wiping.

-

Clean Processing: Laundered in ISO Class 4–5 facilities, ensuring minimal NVR and ionic extractables.

-

ESD Control: Some wipes integrate conductive fibers or coatings for static dissipation.

How They Work:

-

Particle Capture: Textured surfaces trap submicron particles without scratching delicate wafer surfaces.

-

Residue Minimization: Low-NVR wipes prevent chemical films that could distort lithography.

-

Ion Control: Premium wipes keep ionic contamination below 1 μg/g (verified via ion chromatography).

-

Static Mitigation: ESD-safe wipes reduce charge buildup during handling and tool cleaning.

Where Cleanroom Wipers Protect Yield in the Fab

Choosing the right wiper isn’t one-size-fits-all—different fab zones require specialized materials.

| Fab Zone | Application | Recommended Wiper |

|---|---|---|

| Lithography Bay | Mask and lens cleaning | Ultraclean polyester with sealed edge |

| Wet Benches | DI water/solvent wiping | Acid-resistant polyester wipes |

| CMP & Etch Areas | Post-process cleaning | Microfiber wipes (high absorbency) |

| Tool Maintenance | Surface prep & solvents | Polyester-cellulose blends |

Pro Tip: Pair wipes with validated cleaning solutions and ESD protocols for maximum effectiveness.

Critical Metrics When Selecting Semiconductor Wipes

When evaluating wipes for fabs, focus on data, not marketing claims. The following benchmarks align with IEST and SEMI recommendations:

| Parameter | Industry Standard |

|---|---|

| Particle Release (≥0.5μm) | <15 particles/cm² |

| NVR (mg/m²) | <0.5 |

| Ionic Content | <1 μg/g (Na⁺, Cl⁻, K⁺) |

| Edge Finish | Laser or ultrasonic sealed |

| Packaging | Double-bagged, ISO Class 5+ |

The Yield Impact

Let’s talk numbers: Reducing particulate and NVR contamination even modestly can improve wafer yield by 2–5%. For a fab producing 50,000 wafers a month, that’s millions in additional revenue, just by choosing the right wiping protocol.

Benefits Beyond Yield:

-

Lower rework and scrap rates.

-

Reduced tool downtime and maintenance costs.

-

Improved device reliability and customer satisfaction.

Conclusion:

Cleanroom wipers are not an afterthought—they’re an essential element of contamination control. In an industry where nanometers define success, the right wiper can safeguard yield, improve throughput, and protect your bottom line. Invest in precision wipes and validated protocols—it’s one of the simplest, most cost-effective steps toward higher fab performance.

FAQ

Q: Why can’t I use industrial wipes in semiconductor fabs?

A: Generic wipes release fibers, ions, and residues that compromise wafer surfaces, leading to defects.

Q: What’s the most critical wiper spec for lithography?

A: Ultra-low NVR and sealed edges to avoid film defects on optics and wafers.