Global Semiconductor Industry Overview

The semiconductor industry is the backbone of modern electronics, powering computers, smartphones, automotive systems, and industrial equipment. Over the past decade, global demand has surged, driven by AI, IoT, 5G, and automotive electronics.

Asia dominates production, with mainland China, Taiwan, South Korea, and Japan hosting major fabrication facilities. North America and Europe primarily focus on design, high-end manufacturing, and advanced R&D. Emerging regions are gradually expanding capacity but still lag in high-end processes.

Technological advancement is pushing toward smaller line widths, higher packaging density, and more complex chips. These developments increase process sensitivity, making cleanroom consumables critical for production stability. Automation and smart manufacturing improve efficiency but demand higher consistency in consumables.

Key Steps in Semiconductor Manufacturing

Wafer Fabrication

Wafer fabrication involves photolithography, etching, ion implantation, chemical vapor deposition, and thin-film deposition. Each step is extremely sensitive to particles, chemical residues, and electrostatic discharge. Contamination can compromise yield, device performance, and reliability.

Packaging and Testing

Chip packaging includes wafer dicing, die bonding, solder paste printing, reflow soldering, and functional testing. Solder paste printing is especially sensitive; residual paste can cause bridging or insufficient deposits. Cleanroom consumables ensure consistent cleaning of stencils and equipment.

Cleanroom Dependency

Different stages require varying cleanroom standards. High-precision wafer fabrication often demands ISO 3–5 level environments, while packaging and testing typically use ISO 4–6. Controlling particle counts, non-volatile residues (NVR), ions, and static is essential across all stages.

Cleanroom Requirements in Semiconductor Manufacturing

Cleanroom standards dictate air cleanliness, humidity, and electrostatic control. ISO 3–5 cleanrooms allow minimal airborne particles, typically below 1,000 particles per cubic meter for particles ≥0.1 µm.

Non-volatile residues (NVR) from lubricants, solvents, or consumables must be minimized. NVR can interfere with solder paste adhesion, affect thin-film deposition, and reduce device reliability.

Ion contamination is another critical concern. Metallic ions like Na⁺, K⁺, and Cl⁻ can compromise circuit integrity. High-density circuits are particularly sensitive to ionic contamination.

Electrostatic discharge (ESD) is a constant threat. Static can damage bare dies and microcircuits instantly. Cleanroom consumables are engineered to be ESD-safe, grounding personnel and tools effectively.

Core Cleanroom Consumables

Semiconductor cleanroom consumables are specialized products designed to maintain high cleanliness, ESD safety, and operational efficiency. They can be divided into six functional categories: wipes & surface cleaning, floor & entryway cleaning, cleaning chemicals, personnel protection, ESD control, and daily auxiliary supplies.

Wipes and Surface Cleaning Materials

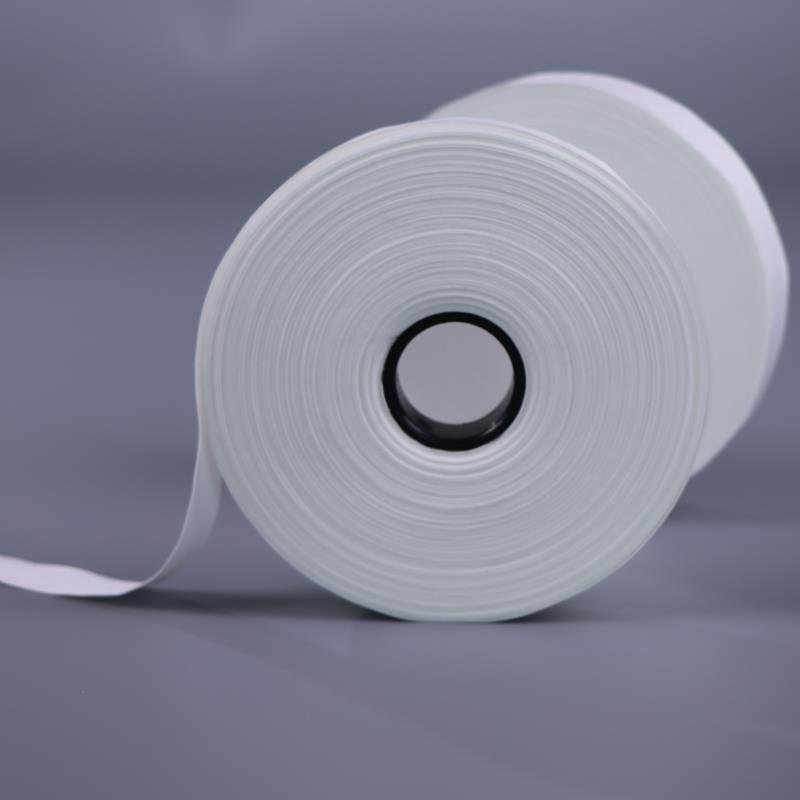

Wipes are essential for cleaning critical surfaces, tools, and equipment.

-

Cleanroom Wipers / Lint-Free Wipes: Made of polyester, ultra-fine fibers, or premium blends, these wipes remove solder paste residues, oils, dust, and chemical residues. Pre-saturated IPA variants offer convenient solvent application. Key properties include high absorbency, durability, and minimal fiber shedding.

-

Cleanroom Swabs: Foam or polyester-tipped swabs are ideal for narrow or hard-to-reach areas, such as tool nozzles, sensor housings, wafer handling components, and precision optical parts. They are low-lint and chemical-resistant.

-

Pre-Saturated Cleaning Wipes: IPA or solvent-impregnated wipes enable quick, consistent cleaning without manual solvent handling, improving safety and process repeatability.

These wipes are vital for preventing contamination-related defects, and supporting high-yield production.

Floor and Entryway Cleaning Materials

Preventing external particle ingress is critical.

-

Sticky Mats: Placed at cleanroom entrances to capture dust and debris from footwear. Multi-layer mats allow peeling of top layers as they become contaminated, ensuring consistent cleanliness.

- In addition to disposable mats, Reusable and Washable Sticky Mats are also used in semiconductor facilities. These reusable mats rely on a permanent tacky surface that can be cleaned with water, allowing repeated use without adhesive layers. Washable tacky mats are often selected for high-traffic entrances, equipment transfer zones, or cost-sensitive operations, where long-term durability and stable particle capture performance are required.

-

Cleanroom Mop Heads & Handles: Lint-free mop systems are used for daily floor cleaning. Designed to remove particles without generating additional contaminants, they support ISO 3–5 cleanliness levels.

-

Vacuum Cleaner Consumables: HEPA-filtered vacuum bags and filters are essential for cleanroom vacuums, capturing particles without reintroducing them into the environment.

These materials help maintain floor-level cleanliness and prevent contamination from entering critical production zones.

Cleaning Chemicals

Chemical consumables are necessary for safe and effective surface cleaning.

-

IPA (Isopropyl Alcohol) Solvent: Widely used for removing residues from stencils, tools, and equipment surfaces. Its volatility ensures rapid drying without leaving residues.

-

Neutral Cleaners / Solvents: Used for daily cleaning of equipment, benches, and floors, neutral solutions are gentle yet effective, ensuring surfaces remain particle-free without damaging materials.

Proper chemical selection prevents chemical contamination and maintains consistent cleanroom performance.

Personnel Protection and Cleanroom Apparel

Human operators are a major source of contamination. Specialized apparel controls particle shedding and ESD risk.

-

Cleanroom Garments / Bunny Suits: Coveralls, gowns, and suits designed for ISO cleanroom levels prevent particle shedding from personnel. Static-dissipative fabrics ensure ESD safety.

-

Head and Face Protection: Hoods, caps, hairnets, and face masks (3-ply, N95, or ISO-compliant) prevent hair and skin particles from entering critical areas.

-

Footwear Protection: Shoe covers, ESD slippers, and sleeve/arm cuff sealers reduce contamination from movement and maintain garment integrity.

-

Gloves: Powder-free nitrile or ESD-safe gloves protect surfaces from oils, dust, and static. Frequent glove changes prevent accumulation of particles.

These consumables are essential to maintaining cleanroom integrity while allowing personnel to operate safely and comfortably.

Electrostatic Discharge (ESD) Control Consumables

ESD control is critical for protecting sensitive semiconductor devices.

-

ESD Bench Mats and Flooring: Prevent static buildup on work surfaces and floors.

-

ESD Wrist Straps and Footwear: Ensure personnel are continuously grounded.

-

ESD Monitoring Devices and Labels: Track and verify ESD safety compliance.

-

ESD-Compatible Waste Containers: Prevent static accumulation in discarded materials.

ESD consumables reduce the risk of device damage and process variability caused by uncontrolled static discharge.

Daily Consumables and Auxiliary Supplies

These materials support operational consistency and documentation without introducing contamination.

-

Cleanroom Trash Bags: Lint-free and ESD-compatible, suitable for sensitive environments.

-

Cleanroom Stationery: Anti-static pens, labels, and folders allow safe record-keeping.

-

Process Records & Logs Paper: Low-lint, anti-static paper used for documenting cleaning, inspection, or production data.

Even seemingly minor consumables play a critical role in maintaining ISO cleanliness and operational traceability.

Semiconductor manufacturing relies on rigorous contamination control and precise cleanroom management. The consumables outlined above—wipes, sticky mats, chemicals, apparel, ESD controls, and auxiliary materials—are essential for achieving high yields and maintaining device quality.

Myesde provides a full range of semiconductor-grade cleanroom consumables. Our products can be customized in material, size, and configuration to meet your production requirements.

Contact Us

Email: info@cldzcl.com