Cleanroom swabs are used in places where standard wipes cannot reach—narrow channels, recessed edges, optical housings, and other precision areas that require targeted, controlled cleaning.

In semiconductor, optics, data storage, and medical-device assembly, these locations often accumulate particles or residues that interfere with performance. Because they are difficult to access and highly sensitive, the cleaning tool itself must add as little contamination as possible.

This is why cleanroom swabs differ significantly from general-purpose cotton or foam swabs. Their materials, construction, and packaging are engineered to meet the cleanliness requirements of controlled environments.

Why Polyester Knit Is Used for Cleanroom Swabs

Most cleanroom-grade swabs use continuous-filament polyester knit fabric for the head. This choice is based on several practical reasons:

-

Low fiber shedding: The continuous filament structure minimizes loose fibers, unlike cotton or paper tips.

-

Strong solvent compatibility: Polyester tolerates IPA, acetone, and other organic solvents commonly used in precision cleaning.

-

Stable mechanical strength: The knit pattern provides a uniform surface that resists abrasion.

-

Low ionic contamination: Polyester inherently carries low levels of mobile ions, reducing the risk of residue transfer.

Compared with foam tips, knitted polyester offers better resistance to particle release and is more suitable for Class-controlled processes, especially where solvent-based cleaning is required.

Why Cleanroom Laundering Is Necessary

Even high-quality polyester material needs further processing before it can be used in critical environments.

Cleanroom laundering removes:

-

loose fibers from the knitting process

-

residual particles

-

ionic contaminants such as sodium, potassium, or chloride

-

non-volatile residues (NVR)

Laundering also stabilizes the surface finish of the swab head, reducing variability between batches.

For industries such as semiconductor or optics, this is essential for consistent and predictable performance.

Why Double-Layer Knit Heads Are Used

A double-layer construction is common in precision swabs because it offers several functional advantages:

-

Improved absorbency: Two layers increase the surface area and liquid uptake.

-

Higher durability: The added thickness provides better resistance to friction.

-

More uniform contact surface: This helps maintain even pressure when cleaning small components.

-

Reduced risk of breakthrough: The internal structure stays intact even when used with aggressive solvents.

Double-layer knit heads offer a balance of strength and softness, allowing effective cleaning without scratching sensitive surfaces.

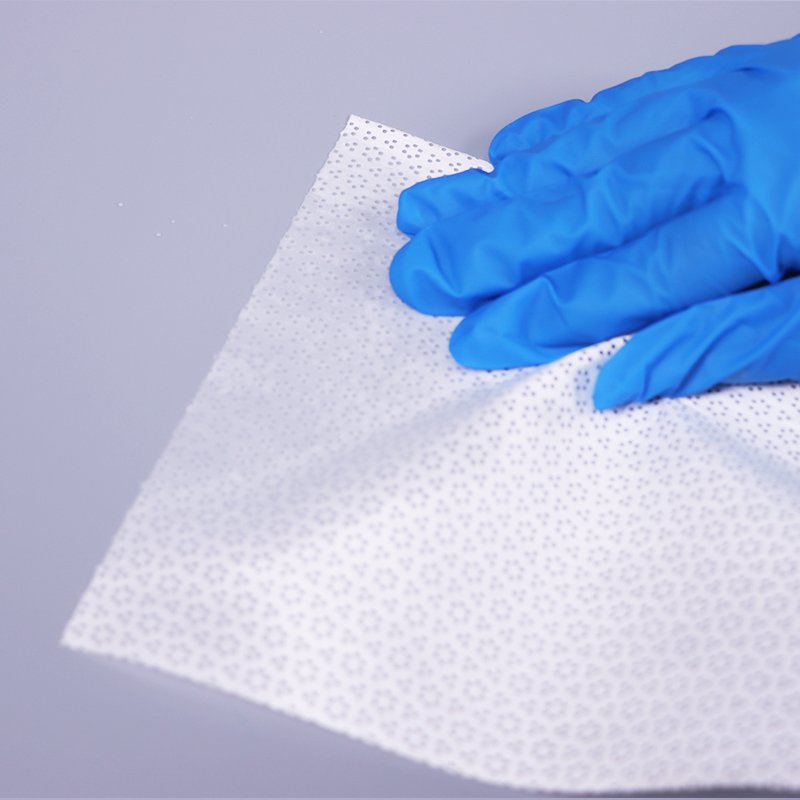

Why Flexible Paddle Heads Matter

Many cleaning tasks involve recessed or structured areas—grooves, slots, or edges.

A flexible paddle head helps address this by:

-

fitting into narrow channels

-

maintaining contact across uneven surfaces

-

reaching recessed optical or mechanical areas

-

providing controlled, precise wiping

-

allowing removal of trapped particles without damaging parts

This makes paddle-style polyester swabs suitable for nozzles, print heads, wafer edge handling tools, HDD components, and laboratory instruments.

Construction Principles for Cleanroom Swabs

Cleanroom swabs require stable construction that avoids introducing contaminants.

A common and effective method is thermal bonding, where:

-

the swab head layers are sealed with heat and pressure

-

the head is secured to the handle without adhesives

-

no silicone, amides, or extractables are introduced during assembly

Avoiding adhesives is important because many glues dissolve in solvents and can leave residues. Handles are typically 100% polypropylene due to its low extractable profile and chemical compatibility.

Clean Packaging for Controlled Environments

Packaging is another critical step in maintaining cleanliness.

Cleanroom swabs are generally:

-

double-bagged to support gowning procedures

-

packed in high-purity polyethylene bags

-

free from silicone, amides, or plasticizers

-

equipped with an easy-tear notch for quick access

-

labeled with solvent-resistant inner-pack labels

This ensures swabs can be introduced into controlled environments without introducing additional contaminants.

Myesde Polyester Knit Swabs: How the Design Fits These Requirements

Based on these industry requirements, Myesde cleanroom swabs are built around several core design principles:

-

Head Material: Cleanroom-laundered, double-layer 100% polyester continuous filament knit

-

Construction: Thermally sealed head with no adhesives

-

Handle: 100% polypropylene, rigid yet lightweight

-

Chemical Compatibility: Suitable for IPA, acetone, DI water, and most process solvents

-

Cleanroom Packaging: Double-bagged in high-purity PE with easy-tear and solvent-resistant labeling

-

Applications: Grooved, slotted, recessed areas; optical frames; nozzles; print heads; semiconductor tools; laboratory devices