When it comes to cleaning tools in industrial, automotive, and commercial settings, the choice between shop towels, rags, and disposable wipes can be a subject of debate. While many workers and businesses have traditionally relied on reusable cloths and rags, there is growing recognition that disposable wipes may offer a better overall solution.

A common belief is that reusing rags or shop towels is more environmentally friendly and cost-effective compared to using disposable wipes. However, using rags and shop towels might be introducing more problems than solutions, especially in high-precision environments like manufacturing or food processing, where cleanliness and hygiene are paramount. According to the Kimberly-Clark Professional™ report “Industrial Wipers: How They Impact Product Quality, Productivity, Worker Health & the Environment,” rags and shop towels may actually be hindering manufacturing processes rather than improving them.

The Hidden Risks of Shop Towels and Rags

While shop towels and rags made from cloth materials, including recycled fabrics, seem like a good choice for reducing waste, they come with hidden risks that can compromise product quality and safety.

Inconsistent Quality

One of the biggest challenges with rags and shop towels is their inconsistency. Often, these towels are made from old clothing or random fabric scraps. This means they can vary in size, shape, and material, making them unpredictable and ineffective for certain tasks. Furthermore, rag materials may contain pins, buttons, or metal shavings, which can lead to scratches or imperfections on the surface of the equipment or product being cleaned.

Hygiene Concerns

Rags and shop towels are often reused, meaning they can harbor dirt, bacteria, and chemical residues that could be transferred to the surfaces they are supposed to clean. These contaminants can not only compromise the quality of the product but may also pose a health risk to workers exposed to them regularly.

A 2011 study co-sponsored by Kimberly-Clark Professional and Gradient (an environmental and risk science consulting firm) revealed that workers using up to 12 laundered shop towels a day might be exposed to dangerous levels of antimony, beryllium, cadmium, cobalt, copper, lead, and molybdenum, all of which are toxic heavy metals known to cause serious health issues.

Advantages of Disposable Wipes

On the other hand, disposable wipes offer distinct advantages that can improve both cleaning efficiency and workplace safety.

Hygiene and Consistency

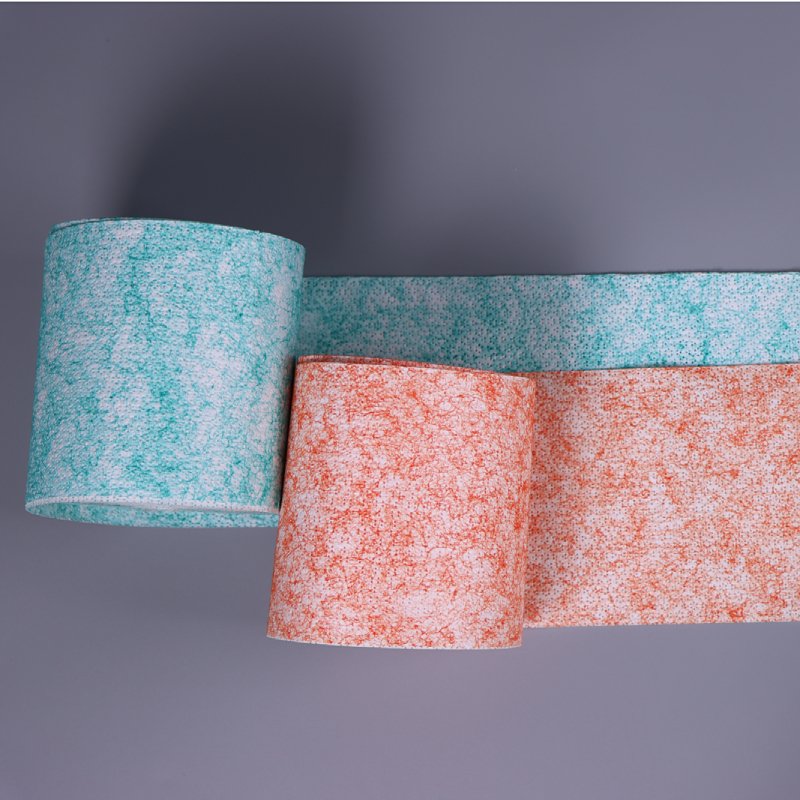

Disposable wipes are designed for single-use, ensuring that they don’t transfer contaminants between cleaning tasks. This is especially important in environments like food processing, cleanrooms, and automotive repair, where maintaining a contaminant-free environment is critical. Since these wipes are manufactured to specific standards, their size, texture, and absorbency are consistent, which makes them far more reliable than rags or towels.

Efficiency and Productivity

Disposable wipes are highly absorbent and engineered for specific tasks, making them efficient tools for cleaning and maintenance. Whether it’s wiping off oil in automotive repair or cleaning equipment in a manufacturing plant, disposable wipes help reduce machine downtime and worker fatigue. Their superior absorbency ensures faster cleaning with fewer wipes, improving overall productivity.

Health and Safety

Unlike reusable rags, disposable wipes eliminate the risk of contamination from heavy metals or chemicals that can cling to reused fabric. Additionally, they are designed to handle oils, grease, dirt, and even some hazardous chemicals, which makes them a safer choice for industrial applications. Workers in environments exposed to harsh chemicals, oils, or even food-grade substances benefit from the assurance that the wipes they use won’t transfer harmful particles or chemicals.

Cost-Effectiveness

While disposable wipes may have a higher per-unit cost compared to rags, they often save money in the long run by eliminating the need for cleaning, storage, and frequent replacement of rags. Additionally, by reducing equipment downtime and product defects, disposable wipes can lead to significant cost savings in manufacturing.

A Comparative Table: Shop Towels and Rags vs. Disposable Wipes

| Criteria | Shop Towels and Rags | Disposable Wipes |

|---|---|---|

| Hygiene | Can harbor bacteria, dirt, and chemicals. | Single-use, minimizing risk of contamination. |

| Consistency | Inconsistent in size, shape, and material. | Designed for uniformity, reliability. |

| Absorbency | Varies depending on material; may not handle large spills. | High absorbency, fast and effective cleaning. |

| Environmental Impact | Reusable, but contributes to laundry waste and wear. | Single-use, but many wipes are biodegradable. |

| Cost | Low initial cost, but higher long-term cleaning and storage costs. | Higher upfront cost, but savings on cleaning and storage. |

| Durability | Can wear out quickly, leading to higher long-term costs. | More durable for specific tasks but for single use only. |

| Safety | Can introduce contaminants, including metal fragments. | Clean, safe, and specifically designed for industrial use. |

Conclusion

While shop towels and rags have long been the traditional choice for cleaning tasks, the advantages of disposable wipes are becoming more apparent in terms of hygiene, productivity, and safety. Disposable wipes not only provide consistent, effective cleaning, but they also eliminate the risk of contamination from recycled materials and reduce the likelihood of defects in manufacturing processes.

For industries that require precision and cleanliness, such as automotive, manufacturing, and food processing, switching to disposable wipes can be a more efficient, cost-effective, and safer option. When evaluating whether to use rags or disposable wipes, it’s important to consider the task at hand, the level of cleanliness required, and the long-term benefits to worker health and product quality.

-3.jpg)