Jiangsu Province,China

24/7 Customer Service

WhatsAPP/Wechat

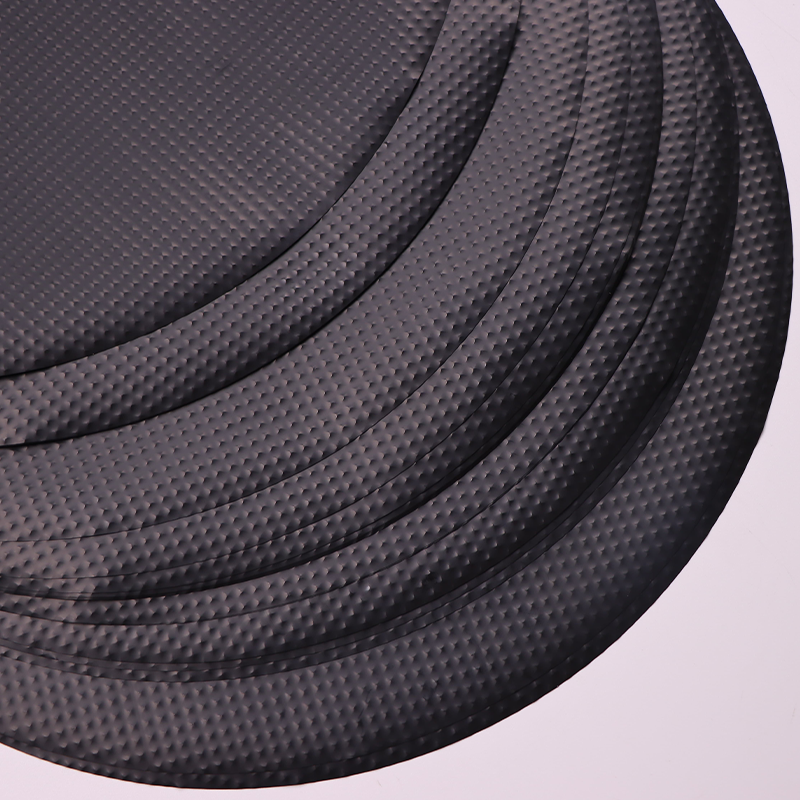

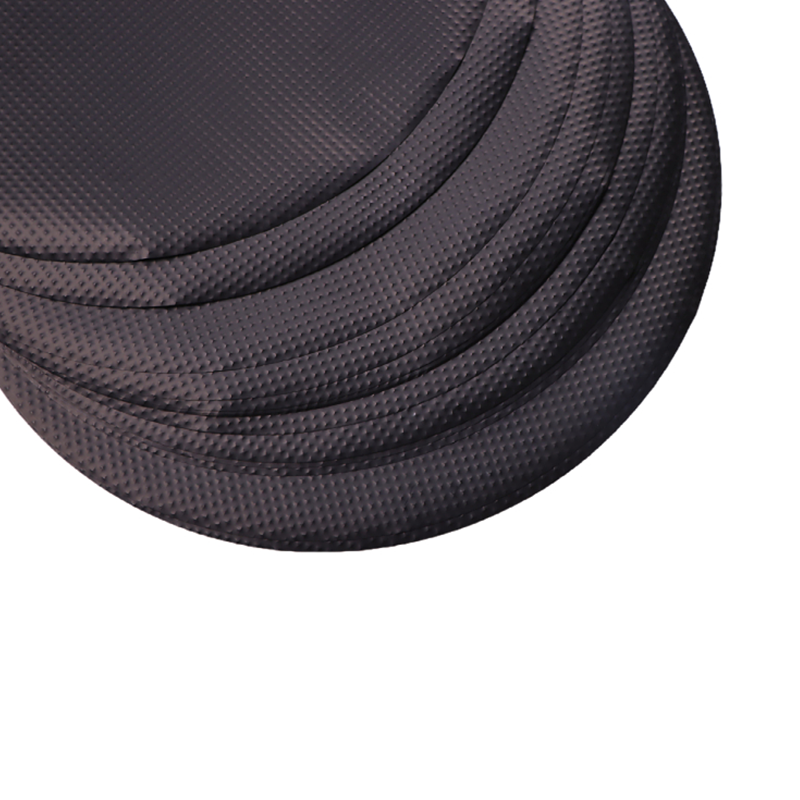

Wafer Spacer Paper ESD (Electrostatic Discharge) is a specialized product designed for use in the semiconductor industry, providing effective protection for wafers during storage, transport, and processing. This paper spacer is engineered to prevent electrostatic discharge, which can damage sensitive semiconductor devices and wafers.

Did We Answer Your Question?

Suzhou Myesde Ultra Clean Technology Co.,LTD

Building 5, Wenyuan Industrial Park, Dongwu South Road, Wuzhong District,

Suzhou, China

Tel / WhatsApp / Wechat: +86-137-7631-4975

E-mail: info@cldzcl.com

Copyright © 2025. Suzhou Myesde Ultra Clean Technology Co.,LTD

We’re ready to provide fast, knowledgeable support.