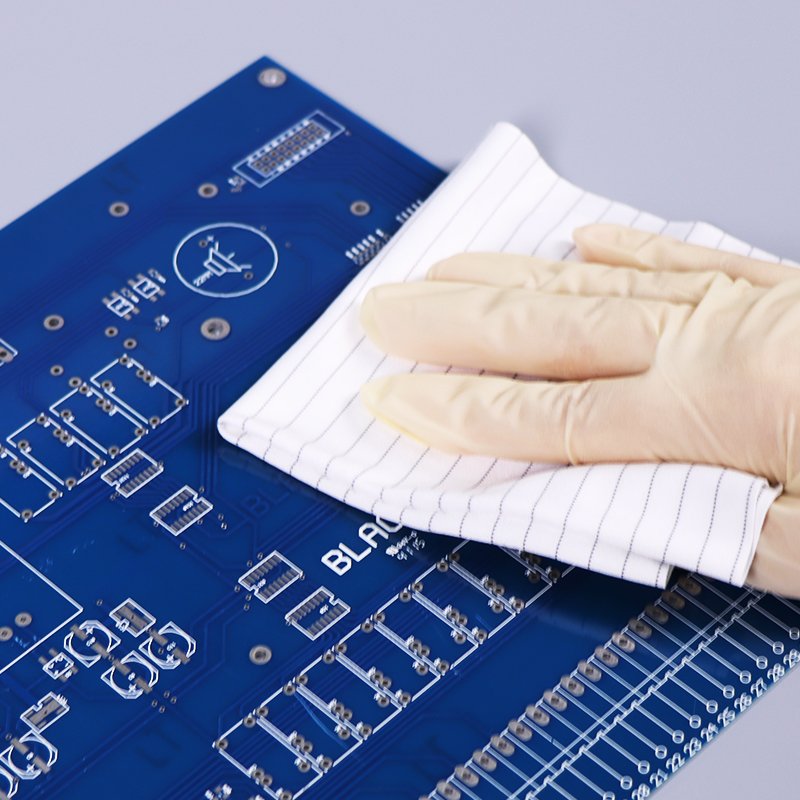

Nonwoven cleanroom wipes are essential tools in contamination-sensitive environments—from semiconductor fabs to pharmaceutical cleanrooms. But what exactly are these wipes made of, and how do their material compositions affect performance?

In this article, we break down the materials, manufacturing methods, and critical performance characteristics that define nonwoven cleanroom wipes. You’ll also gain practical insights into choosing the right wipe for your cleanroom class, as well as the hidden factors that could compromise your contamination control protocols.

What Does “Nonwoven” Actually Mean?

The term nonwoven refers to a fabric that is not woven or knitted but bonded together through mechanical, chemical, or thermal processes. In contrast to traditional textiles, nonwoven materials are engineered from staple fibers or filaments that are entangled or fused to form a sheet-like fabric.

In cleanroom applications, nonwoven fabrics must meet extremely high cleanliness standards, including:

-

Low particle generation (APC/LPC)

-

Minimal fiber shedding

-

High liquid absorbency

-

Chemical compatibility

The raw material and bonding method used will determine whether a wipe is suitable for ISO Class 5 environments or limited to less critical zones like ISO Class 8.

Common Base Materials Used in Nonwoven Cleanroom Wipes

1. Polyester (PET)

-

Overview: A synthetic polymer known for strength, low particle shedding, and solvent resistance.

-

Benefits:

-

Compatible with IPA and many solvents

-

Very low linting

-

Suitable for ISO Class 5–7 environments

-

-

Drawbacks:

-

Lower absorbency compared to natural fiber blends

-

Polyester is often used in spunlace or thermal-bonded wipes, and sometimes blended with cellulose to enhance absorbency while maintaining durability.

2. Polypropylene (PP)

-

Overview: A hydrophobic polymer is often used in meltblown and spunbond nonwoven wipes.

-

Benefits:

-

Economical

-

Good chemical resistance to acids and bases

-

-

Drawbacks:

-

Poor absorbency unless treated

-

Generates more fibers than PET in low-end variants

-

Meltblown polypropylene wipes are commonly used in pre-saturated wipes for general cleanroom surface cleaning.

3. Cellulose (Wood Pulp)

-

Overview: A natural fiber with excellent absorbency and softness.

-

Benefits:

-

Rapid absorption of aqueous and solvent-based liquids

-

Low cost

-

-

Drawbacks:

-

Less durable than synthetic fibers

-

Can shed particles when dry

-

Not ideal for sterile or ISO 5+ areas

-

Cellulose is often blended with polyester or polypropylene to balance absorbency and cleanliness.

4. Rayon

-

Overview: A regenerated cellulose fiber with smoother texture and slightly higher strength than natural cellulose.

-

Use Case: Often found in blended wipes (e.g., 55% cellulose / 45% rayon) for general-purpose wiping in Class 7–8 cleanrooms.

Manufacturing Methods That Matter

The manufacturing process plays a critical role in how well a wipe performs in your cleanroom environment. Here are some of the key nonwoven fabrication techniques:

| Method | Process Description | Typical Use |

|---|---|---|

| Spunlace | Hydroentanglement of fibers using high-pressure water jets | Durable, soft wipes for ISO 5–7 |

| Meltblown | Fine fibers are extruded and bonded via hot air | Low-cost wipes, moderate cleanliness |

| Thermal Bonding | Fibers fused using heat | Structured wipes with minimal chemical use |

| Needlepunch | Fibers are mechanically entangled using barbed needles | Rare in cleanroom-grade wipes (too fibrous) |

Each method has implications on particle shedding, solvent compatibility, and structural integrity.

Why Material Composition Affects Performance

Depending on the base polymer and bonding method, cleanroom wipes can behave very differently. Consider the following performance metrics:

| Material Type | Absorbency | Linting | Solvent Resistance | Cleanroom Suitability |

|---|---|---|---|---|

| 100% Polyester (Spunlace) | Moderate | Very Low | Excellent | ISO 5–7 |

| Polypropylene (Meltblown) | Low–Moderate | Moderate | Good for Acids | ISO 7–8 |

| Polyester/Cellulose Blend | High | Low | Good | ISO 6–8 |

| 100% Cellulose | Very High | High | Low (Breaks down) | ISO 8 only |

Industry Insight: “The Absorbency Trap”

One of the most common misconceptions in purchasing nonwoven cleanroom wipes is equating absorbency with performance. Many high-absorbency wipes (like 100% cellulose) are actually too fibrous and unsuitable for critical ISO 5–6 environments due to particle shedding.

A more balanced wipe—like a 55% cellulose / 45% polyester blend—offers excellent liquid pickup with much lower particle release, making it a safer option for electronics, aerospace, or medical device manufacturing.

Choosing the Right Wipe: Don’t Just Look at Price

Here’s what professional cleanroom buyers consider beyond just specs:

-

Border Sealing: Heat-sealed edges reduce linting

-

Gamma Sterilization: Needed for pharma or bioscience

-

Pre-saturated vs. Dry: Solvent pre-wetted wipes can improve consistency

-

Packaging Format: Double-bagging for cleanroom entry protocols

👉 If your wipes are causing visible streaks or leaving behind fibers under a microscope, it’s time to reassess your material selection.

Future Outlook: Eco-Friendly Alternatives

As sustainability becomes a procurement priority, several cleanroom manufacturers are exploring:

-

Biodegradable wipes made from PLA or bamboo fiber

-

Recyclable packaging for wipe refills

-

Reusability protocols in ISO 8–9 areas using autoclavable synthetic wipes

Although not yet mainstream for ISO 5–6 applications, these green solutions are gaining interest in pharmaceutical packaging, battery plants, and laboratories.