In ultra-critical environments, cleanliness isn’t just about appearance—it’s about removing the invisible. Among the most elusive and hazardous contaminants are endotoxins: microscopic molecules that can compromise pharmaceutical sterility, damage sensitive components, and trigger severe biological reactions.

This is where low-endotoxin wipes come in. They go beyond standard cleanroom wipes, offering specialized performance that helps manufacturers meet the strictest regulatory standards in life sciences, microelectronics, and precision optics.

In this article, we’ll unpack what low-endotoxin wipes are, what makes them different, why they matter—and most importantly, when they’re worth the investment.

What Are Endotoxins?

Endotoxins are a type of pyrogen (fever-inducing substance) that originate from the outer membrane of Gram-negative bacteria. Unlike live bacteria, endotoxins can remain active even after sterilization processes, meaning that traditional antimicrobial cleaning isn’t enough.

These toxic molecules pose a serious threat in regulated industries, especially:

-

Biopharmaceutical manufacturing

-

Medical device assembly

-

Cell and gene therapy cleanrooms

-

Microfluidic and implantable component production

Even trace levels of endotoxins can cause adverse reactions in patients or lead to product recalls due to regulatory non-compliance.

What Are Low-Endotoxin Wipes?

Low-endotoxin wipes are cleanroom-grade wipes that are specifically designed and manufactured to have extremely low endotoxin levels—typically less than 20 EU (endotoxin units) per device or <0.5 EU/m² of surface area. These wipes undergo rigorous washing, packaging, and testing processes to minimize bioburden and endotoxin residue.

Key Characteristics:

-

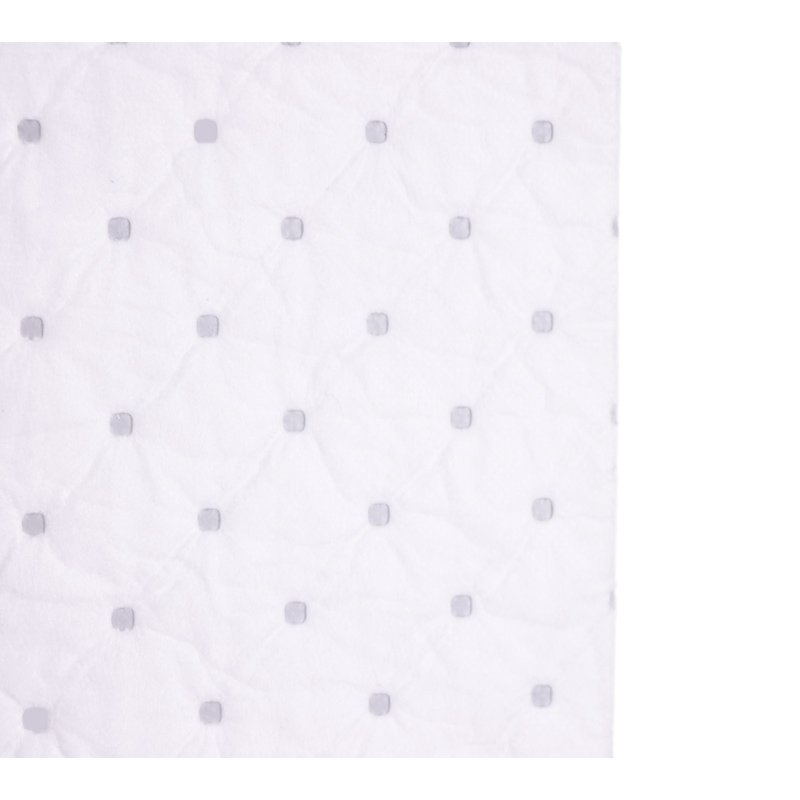

Made from nonwoven or knit synthetic fibers like polyester or polypropylene

-

Double or triple-washed with Water-for-Injection (WFI) or 18 MΩ ultra-pure water

-

Produced and packaged in ISO Class 5 or better cleanrooms

-

Often gamma-irradiated or autoclaved for sterility

-

Certified for low endotoxin levels, usually with validated LAL (Limulus Amebocyte Lysate) test results

How Are They Different from Regular Cleanroom Wipes?

| Feature | Standard Cleanroom Wipes | Low-Endotoxin Wipes |

|---|---|---|

| Endotoxin Control | Not guaranteed | Tested and certified (<0.5 EU/m² typical) |

| Cleanliness Class | ISO 5–7 | ISO 3–5 |

| Laundering Process | Deionized or filtered water | Ultra-pure WFI, endotoxin-reducing washes |

| Packaging Environment | Cleanroom | Sterile ISO 5+ or aseptic packaging |

| Applications | General cleanroom tasks | Biopharma, injectables, implantables |

| Cost | Lower | Higher but more targeted |

When Are Low-Endotoxin Wipes Necessary?

Not all cleanroom tasks require low-endotoxin wipes. But when the stakes are high, failing to use the correct wipe can result in costly consequences:

1. In Pharmaceutical Cleanrooms

Sterile injectable drug products must meet FDA and EU pharmacopoeia limits for endotoxins. Using standard cleanroom wipes may leave behind pyrogens, putting product batches—and patients—at risk.

2. In Medical Device Manufacturing

Implantable devices like stents, catheters, and pacemakers must be endotoxin-free. Even minute residues from a standard wipe can result in failed QC testing, product rejection, or worst-case—adverse reactions post-implantation.

Real-World Scenario:

A medical device assembler used general ISO Class 5 wipes for cleaning titanium orthopedic screws. The product batch repeatedly failed endotoxin testing. Switching to validated low-endotoxin wipes resolved the issue within two production runs.

3. In Cell & Gene Therapy Facilities

The fragility of living cells and viral vectors used in CGT platforms makes them extremely vulnerable to biological contaminants. Using wipes with unknown endotoxin loads can lead to inconsistent outcomes or treatment failure.

Common Customer Pain Points: Why This Matters

Low-endotoxin wipes aren’t just about compliance—they’re a safeguard against costly mistakes:

-

QC Failures: Residual endotoxins on equipment surfaces can trigger failed sterility or pyrogen testing, causing batch delays and extra testing costs.

-

Invisible Contamination: Endotoxins aren’t visible to the eye—clean-looking surfaces can still harbor high-risk biological residues.

-

Procurement Errors: Teams unaware of endotoxin specs may purchase wipes with only ISO class ratings, not realizing they’re insufficient for injectable or implantable product use.

-

High Cost, Low Value: Not all “low endotoxin” labeled wipes are truly certified—some lack LAL test validation or relevant batch traceability, resulting in high-cost but ineffective cleaning.

What to Look For in a Low-Endotoxin Wipe

When evaluating wipes, especially for GxP-regulated environments, verify the following:

-

Endotoxin Certificate (batch-specific, with EU/m² or EU/device level)

-

LAL Assay Compliance (USP <85>)

-

Gamma-Irradiation or Autoclave Sterility Certification

-

Documentation for Traceability (lot number, production date, etc.)

-

Material Compatibility (suitable for surfaces like stainless steel, titanium, glass, etc.)

Final Thoughts

Low-endotoxin wipes may not be necessary in all cleanroom environments, but for high-stakes industries like biopharma and medical device manufacturing, they are essential. These wipes serve as a critical barrier to invisible pyrogens that can derail production, risk patient safety, and damage a brand’s credibility.

They are not simply “cleaner wipes.” They are purpose-engineered tools that help safeguard the most sensitive workflows.

When choosing cleanroom wipes, evaluate not just ISO class or absorbency—but the invisible threat of endotoxins. Because what you can’t see could cost you everything.

-3.jpg)