What Is Cleanroom Cleaning and Maintenance

Cleanroom cleaning and maintenance is a systematic and regulated process aimed at eliminating contamination sources—particulate, microbial, and chemical—to maintain a controlled environment according to ISO or GMP standards. It involves both scheduled cleaning routines and ongoing upkeep of facility components and consumables.

The Core Objectives of Cleanroom Maintenance

-

Particulate control

-

Microbial load minimization

-

Chemical residue control (e.g., NVR)

-

ESD risk reduction

-

Preservation of air filtration and laminar flow integrity

Cleaning Requirements Across Industries

| Industry | Typical ISO Class | Key Contamination Focus |

|---|---|---|

| Semiconductor | ISO 4–6 | Metal ions, static, nano-particles |

| Biopharmaceutical | ISO 5–8 / GMP A–D | Microbial contamination, endotoxins |

| Optics & Display | ISO 5–7 | No scratching, low NVR, ESD |

| Aerospace & Precision | ISO 6–8 | Grease particles, mechanical debris |

Routine vs. Deep Cleaning Procedures

Routine Cleaning

-

Surface wipe-down using cleanroom wipes and IPA

-

Replacing sticky mats and monitoring gowning area traffic

-

Checking air returns, FFUs, and light fixtures

Deep Cleaning

-

Ceiling and high-wall vacuuming using HEPA vacuums

-

Full floor mopping using cleanroom-grade mop systems

-

Filter replacement and microbial swab testing

-

Documentation and logbook review for GMP traceability

Tools, Equipment, and Consumables for Cleanroom Cleaning

Recommended Cleaning Equipment

| Tool / Equipment | Description | Typical Usage |

|---|---|---|

| Cleanroom Wipers | Polyester/microfiber, sealed edges | Wiping surfaces, tools, workstations |

| Mop Systems & Squeegees | For walls, floors, corners | Full-surface cleaning |

| HEPA-filtered Vacuum | For submicron particles | Ceilings, raised floors |

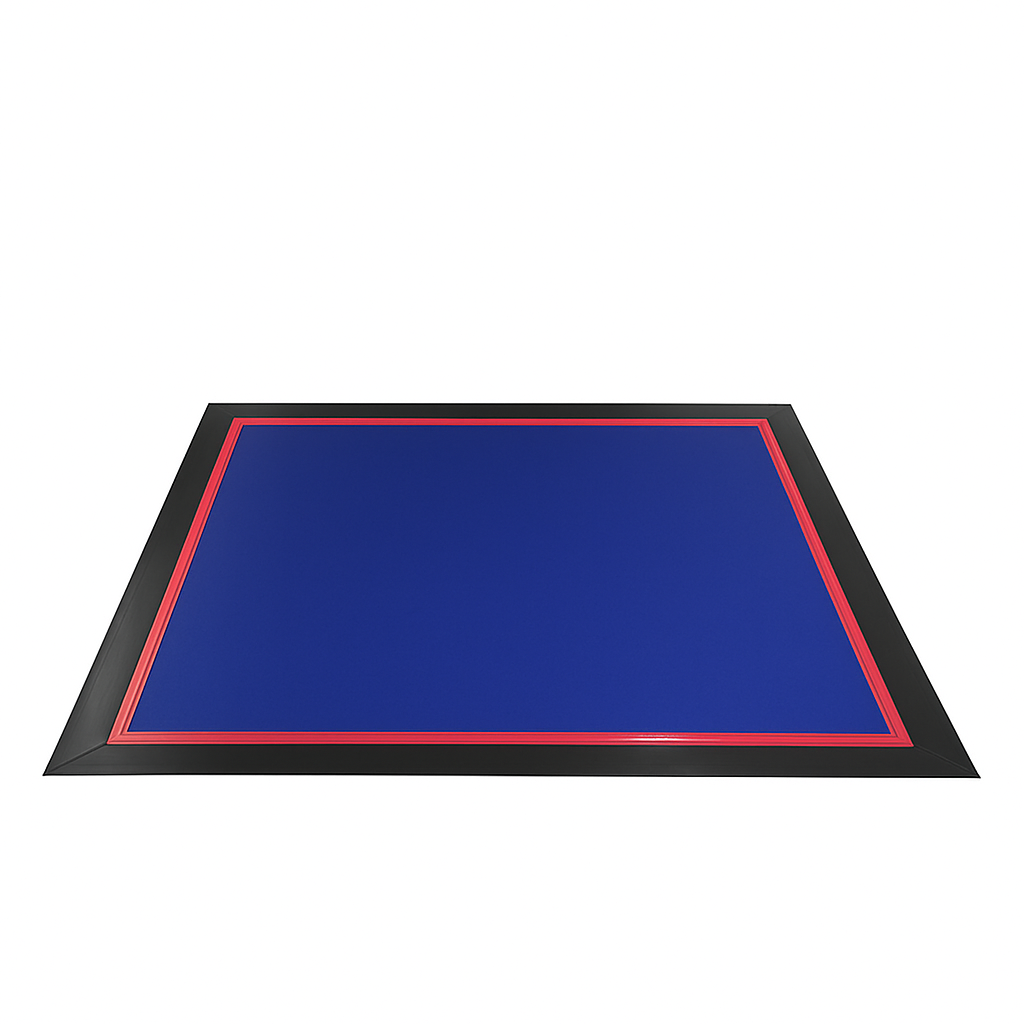

| Sticky Mats / Rollers | Trap particles from shoes or wheels | Entrances, gowning areas |

| Cleanroom Trolleys | Zone-segmented, autoclavable carts | Transport of tools and cleaning sets |

Essential Consumables

| Consumable | Key Properties | Application |

|---|---|---|

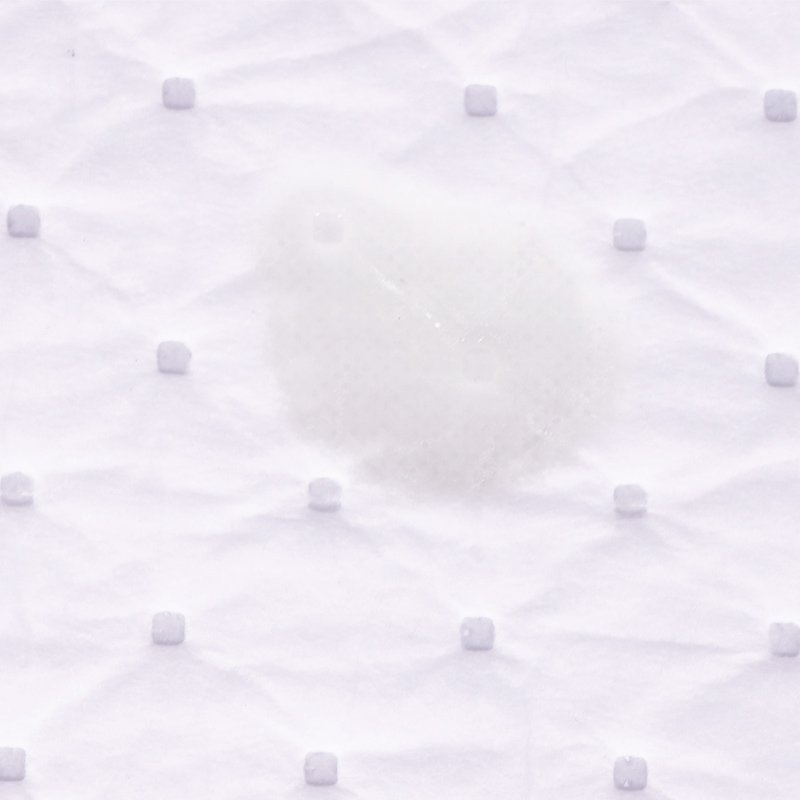

| Lint-Free Wipes | Ultrasonic or laser-sealed, low shedding | ISO 4–7 wiping tasks |

| IPA (70% or 99.9%) | Low residue solvent | General cleaning and disinfection |

| DI Water | For rinsing and NVR-sensitive areas | Optical, LCD cleaning |

| NVR-Tested Solvents | Leaves no chemical film or fog | Semiconductor and optics surfaces |

| Sterile Cleanroom Gloves | Particle- and endotoxin-tested | Biopharma & ISO 5 environments |

Analytical Testing Relevance:

-

APC/LPC (Airborne/Liquid Particle Count): Prevents particle re-release

-

NVR (Non-Volatile Residue): Prevents chemical fogging on surfaces like wafers

-

Ion Contamination Testing: Prevents corrosion and compatibility issues in semiconductors and pharmaceuticals

-

Endotoxin Testing: Critical for medical device and injectable drug production

Cleanroom Cleaning and Maintenance Checklist

Here’s a structured checklist that cleanroom operators can adapt for daily, weekly, and monthly cleaning cycles:

Daily Cleaning Tasks

| Task | Responsible Party | Notes |

|---|---|---|

| Wipe down work surfaces with IPA | Operator | Before and after shift |

| Replace sticky mats | Cleaning staff | Entry/exit areas |

| Clean glass/viewports | Cleaning staff | Lint-free wipes only |

| Sweep and mop floors (if ISO ≥6) | Janitorial staff | Use cleanroom mop system |

| Inspect and clean gowning area | Operator | Use ESD-safe tools |

Weekly Cleaning Tasks

| Task | Responsible Party | Notes |

|---|---|---|

| Vacuum floors and raised access areas | Cleaning staff | HEPA vacuum only |

| Clean and sanitize equipment exteriors | Operator | Use approved solvents |

| Wipe walls and doors | Cleaning staff | Floor-to-ceiling pass |

Monthly / Scheduled Tasks

| Task | Responsible Party | Notes |

|---|---|---|

| Change HEPA/ULPA filters (if applicable) | Facility team | Follow manufacturer guidance |

| Deep clean ceilings and lighting fixtures | Cleaning staff | Use lift tools if needed |

| Recalibrate particle counters / monitors | Quality team | As per SOP |

| NVR and particle testing on surfaces | QA Lab | For Class 100–1000 zones |

Common Mistakes and How to Avoid Them

-

❌ Using household-grade mops or cloths

-

❌ Circular wiping patterns

-

❌ Neglecting hard-to-reach areas like corners or vents

-

❌ Storing cleanroom consumables in uncontrolled zones

-

✅ SOLUTION: Train staff, enforce SOPs, and use validated consumables

Conclusion

Maintaining a cleanroom is not a routine—it’s a critical layer of quality control. By following structured SOPs, using certified equipment and consumables, and maintaining test records (NVR, APC, endotoxins), manufacturers can reduce contamination risk, ensure regulatory compliance, and extend the service life of their facility.

-3.jpg)