For cleanroom Contamination control& ESD Control

Contamination Control Solutions Supplier

21 Years of Cleanroom Product Manufacturing Experience.

Leading Manufacturer of Cleanroom Wipes

Myesde is a leader in cleanroom wiping solutions, with over 20 years of expertise and a reputation for innovation in contamination control. We continuously invest in cutting-edge technology, research, and quality control to ensure our products meet the highest standards. Our state-of-the-art facilities, including a new plant in Nantong, enable us to deliver reliable, high-performance solutions to over 40 top global companies.

Whether you supply the semiconductor, pharmaceutical, or high-precision manufacturing industries, or serve sectors like automotive and electronics, our cleanroom lint-free wipes meet the most stringent quality standards. As a trusted manufacturer, we support global distributors, wholesalers, and trading companies with factory-direct cleanroom consumables that ensure consistent supply, certified quality, and competitive pricing.

Explore Our Best Selling Wipes

Factory-Direct • Certified • Reliable

Experts Serving Key Industries

Myesde’s products are widely usded in semiconductor, storage, new type display, lens,pharmaceuticals and aerospace industries. Myesde is the most recognized name in the ESD control and contamination control industry in China and have found cooperation in many global customers including over 40+ fortune 500 companies, with its high sense of responsibility, R&D ability and perfect guarantee system.

Semiconductor

Pharmaceutical & Medical Device

Precision Electronics

LCD Manufacturing

Precision Optics

Data Storage

WHY CHOOSE US

Suzhou Myesde Ultra-Clean Technology Co., Ltd. is s leading manufacturer of cleanroom wipes for the semiconductor industry

- 20 years Rich export experience in manufacturing.

- Quality: strict quality control to make sure superior quality.

- Delivery Time: 2-7 days after receiving all payment.

- 24H x 7D Excellent Service Team.

- OEM & ODM is available.

Mission

To Prevent Micro-Contamination and Empower High-Tech Industries.

Our Vision

To Become The Most Trusted Partner For High-Tech Enterprises.

Our Mission

To Prevent Micro-Contamination and Empower High-Tech Industries.

Our Values

Focusing on Quality, Innovating Continuously, and Sharing the Fruits of Development.

Visit Our Factory

Fully In-House Production

From Raw Materials to Final Packaging

AA-Grade Yarns

We Use Only Premium AA-Grade yarns, Free from Silicone Additives During Production.

Weaving Machine

With various types of knitting needles such as 28 needles, 38 needles, 42 needles, we can provide customers with different weaving styles.

Cleanig & Dyeing

The use of DI water and non-ionic surfactant for water washing treatment, providing the fabric of clean & low ion pollution and low NVR

Faric Packing

The fabric is packaged with double PE film to prevent outside dust from falling on the fabric

Cutting

We have 10 sets laser machine, 8 sets ultrasonic machine.

Laundering & Drying

Using 18M ultra-pure water to do laundry, in order to ensure the cleanliness of the product.

Inspection & Packing

Visual inspection process and packing is completed in ISO class 4/5 cleanroom.

Finished Wipes

The whole quality management system control to ensure the product stability and traceability.

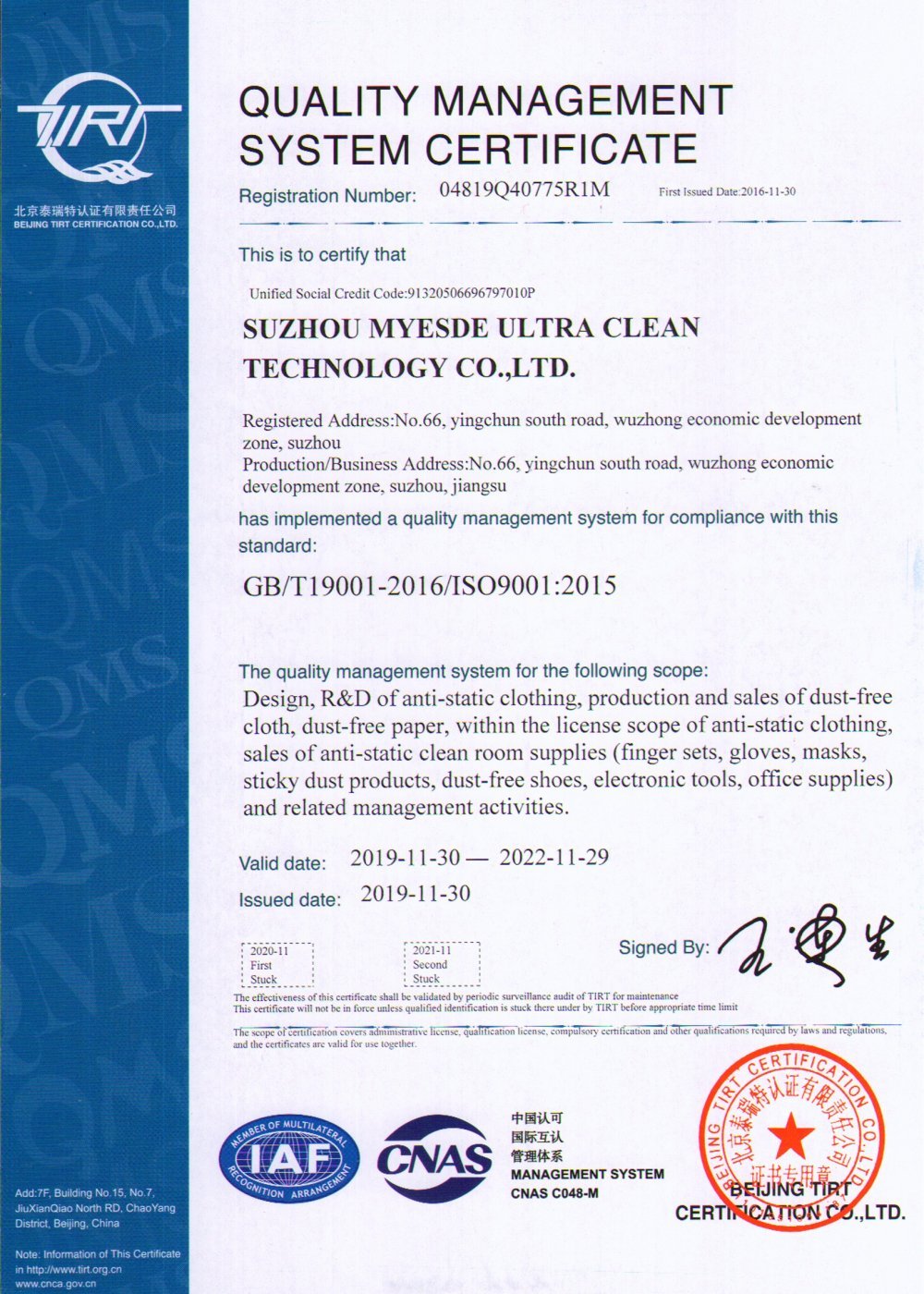

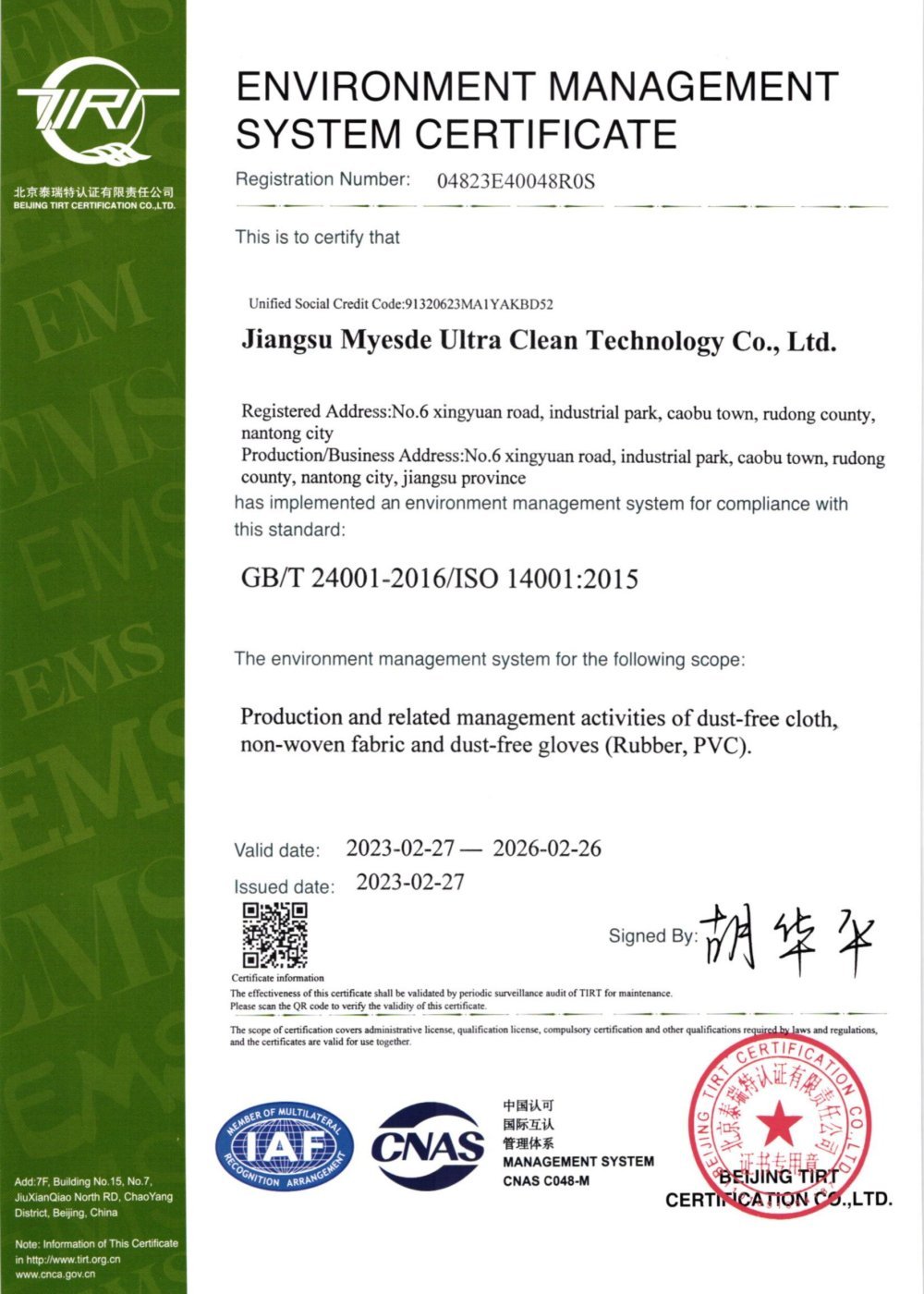

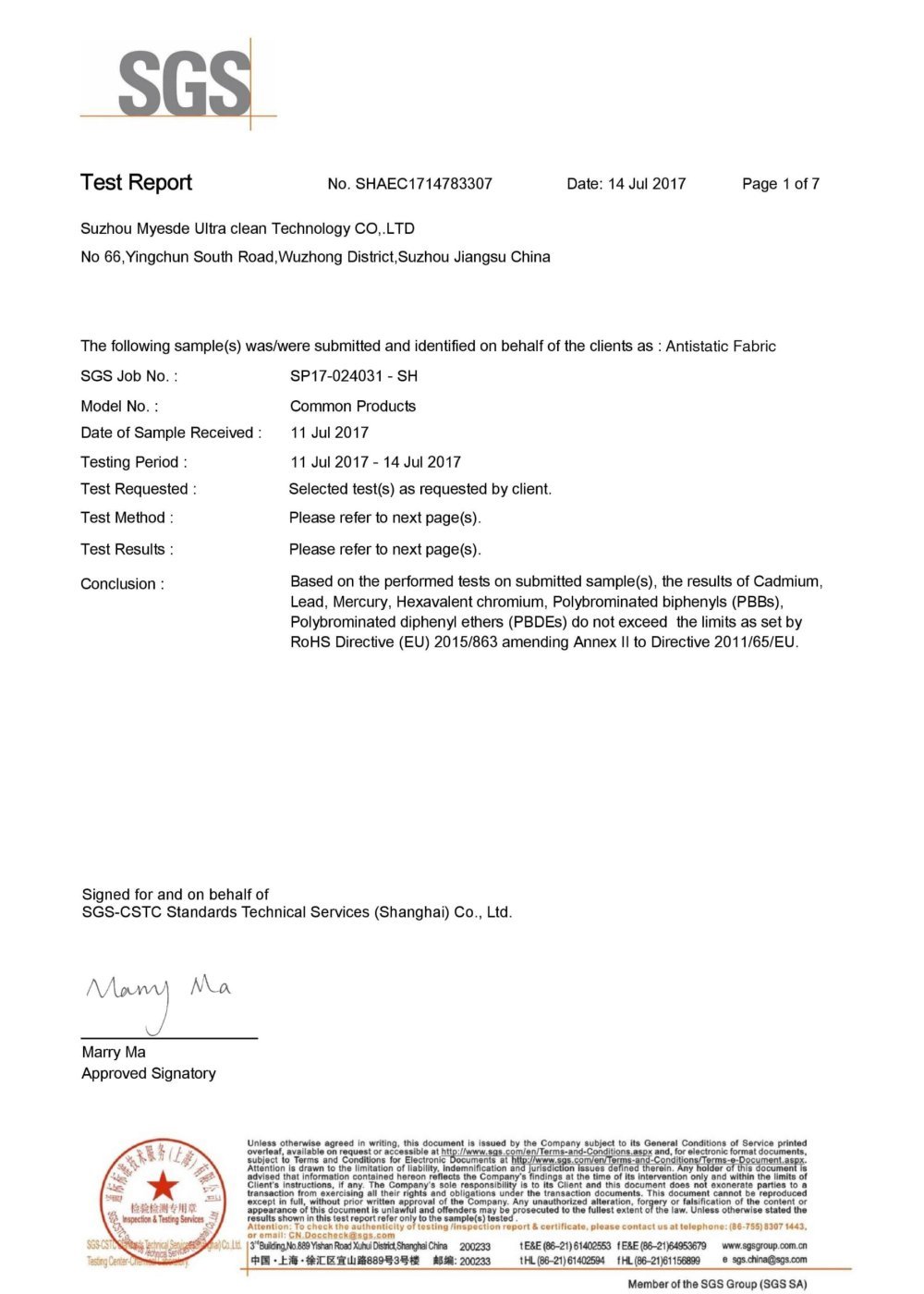

Certifications

Quality Assurance

Attention to detail spans from raw material selection to final packaging.

We manufacture high-performance cleanroom wipers tailored to meet the rigorous standards of your industry.

NEBB and ISO 9001 compliant, our factory enforces strict 100% inspections for every production batch.

Every wiper is tested for NVR, particle release, and absorbency to ensure full compliance with industry standards.

Our cleanroom wipers are built to meet ISO, CE, RoHS certifications—ideal for critical environments demanding the highest cleanliness.

Moments with Our Partners

-4.jpg)