In the fast-paced world of SMT (Surface Mount Technology) assembly, even a minor defect can disrupt production, drive up rework costs, and impact product quality. Stencil wiping rolls, often overlooked, play a pivotal role in ensuring a clean and accurate solder paste printing process—the foundation for a reliable circuit board.

Using the right wiping roll not only helps maintain stencil cleanliness but also directly contributes to higher first-pass yield, reduced downtime, and fewer soldering-related defects.

Why Clean Stencils Matter So Much in SMT

During the printing process, solder paste is applied through a stainless-steel stencil onto the PCB. Over time, paste builds up on the stencil’s underside or within apertures, leading to:

- Bridging – excess paste connecting adjacent pads

- Smearing – blurred edges due to misalignment or contamination

- Solder balls – small solder particles left behind after reflow

- Incomplete prints – blocked apertures, reducing solder volume

These issues are not just cosmetic—they can result in electrical shorts, cold solder joints, or failed in-circuit testing.

High-quality stencil wiping rolls ensure that each print is clean and repeatable, even in high-volume environments running 24/7.

Material Science Behind High-Performance Wiping Rolls

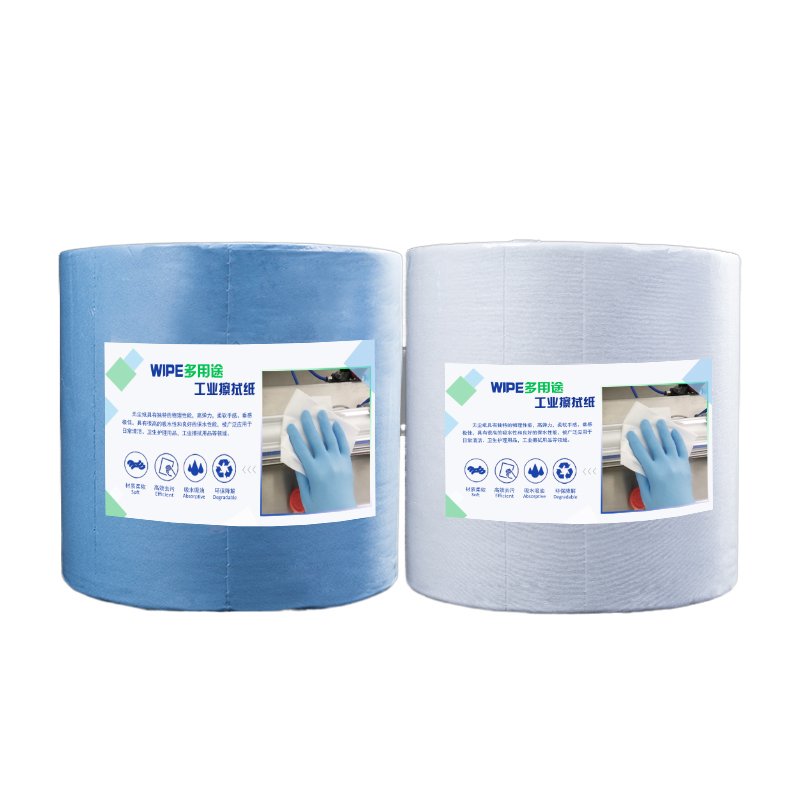

Our stencil wiping rolls are engineered using two distinct materials, each offering unique performance benefits depending on your process requirements:

ESD-Safe Rayon + Polyester Copolymer Roll

This premium-grade material combines coarse rayon and ESD polyester, bonded through a proprietary copolymer process. Designed to withstand rigorous wiping conditions, this roll delivers:

- Exceptional lint control – no loose fibers to contaminate PCBs

- Electrostatic discharge safety – safe for static-sensitive environments

- Strong fiber bonding – resists shredding, tearing, or deformation

- Efficient residue capture – absorbs solder paste and flux into its internal fiber structure

- Wet & Dry Compatible – suitable for solvent-bar and vacuum-assisted systems

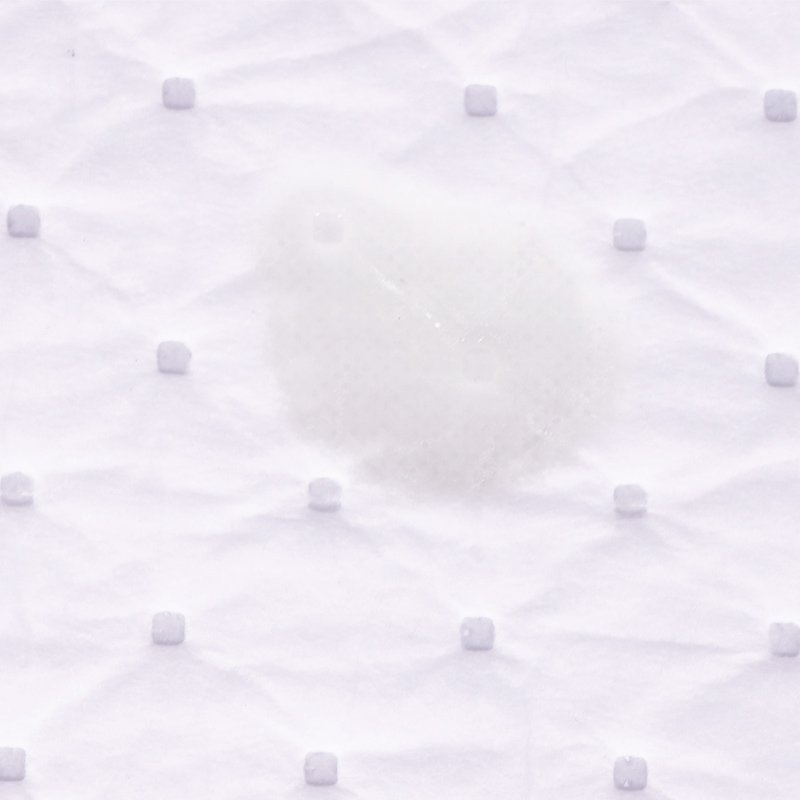

Hydroentangled Wood Pulp + Polyester Roll (Cleanmaster Grade)

This roll is made without chemical binders, using a hydroentanglement process that locks wood pulp and polyester together under high pressure. The result:

- Virtually lint-free wiping surface

- Superior absorbency – ideal for removing paste and adhesives

- High airflow permeability – enhances vacuum-assisted cleaning efficiency

- Economical yet high-performance – perfect balance of quality and cost

Not all hydroentangled blends are created equal—our Cleanmaster-grade material offers a finer balance of strength, absorption, and surface contact, outperforming many generic rolls on the market.

Broad Compatibility with SMT Equipment

We offer stencil wiping rolls that fit virtually all major SMT screen printer platforms, including:

- DEK (Horizon, ELA, NeoHorizon)

- MPM / Speedline (Accela, Momentum)

- EKRA

- JUKI

- Panasonic

- Yamaha

- Samsung

- SJ Innotech

- SpeedPrint

- SMTech (legacy systems)

Custom widths, roll lengths, core types, and packaging options are available upon request to meet your specific line configuration.

Dry vs. Wet Wiping: What’s Best for You?

| Cleaning Method | Description | When to Use |

|---|---|---|

| Dry Wiping | Uses mechanical contact only | When minimal residue is present, fast cycle times |

| Wet Wiping | Involves a solvent bar to break down residues | When solder paste buildup is more aggressive |

| Vacuum-Assisted Wiping | Removes contaminants through suction under the roll | For high-density stencils and cleanroom-level cleaning |

Our rolls are designed to perform consistently across all wiping modes, without tearing or clogging vacuum channels.

Common SMT Defects Caused by Poor Wiping

| Defect Type | Root Cause | Our Roll’s Role |

|---|---|---|

| Bridging | Residue smeared under the stencil | Smooth, consistent wiping removes excess paste |

| Solder balls | Paste deposits left behind dry and migrate | Rolls absorb and trap residue effectively |

| Aperture clogging | Paste remains within stencil holes | Highly absorbent fibers help pull out residues |

| ESD damage | Incompatible materials introduce static | Our rolls are ESD-safe, eliminating this risk |

Using high-quality stencil wiping rolls is a preventive measure that pays off in better production yield and less rework.

Product Performance Highlights

- 🔹 ESD Safe – No static discharge risk to sensitive components

- 🔹 Non-Linting – Will not release loose fibers into your process

- 🔹 Highly Absorbent – Traps solder paste, adhesives, and flux efficiently

- 🔹 Tear Resistant – Withstands high-speed wiping cycles without shredding

- 🔹 Compatible – Performs with or without solvents, vacuum, or dry systems

- 🔹 Customizable – Available in multiple sizes and formats

Frequently Asked Questions

Q: Will your wiping rolls tear or shred under high-speed wiping?

A: No. Both material types are engineered for strength. The copolymer-bonded rayon/polyester and hydroentangled pulp/polyester are both tested for mechanical durability.

Q: Are these rolls cleanroom safe?

A: Yes. Our lint control and packaging processes meet the cleanliness requirements of SMT lines and controlled environments.

Q: Do I need a solvent to use these rolls?

A: Not necessarily. Our rolls are designed to perform dry or wet, depending on your stencil condition and cleaning strategy.

Q: What’s the ESD rating?

A: The rolls are made with conductive polyester blends and tested per industry standards for static dissipation. Detailed ESD data can be provided upon request.

Q: Do you support OEM/ODM orders?

A: Yes. We can customize dimensions, packaging, and private-label branding based on your requirements.

-3.jpg)