What SMT Stencil Cleaning Rolls Are Used For

SMT stencil cleaning rolls, sometimes called stencil wiping rolls or stencil cleaning wipes, are specialized consumables used in surface mount technology printing. They play a critical role in maintaining stable solder paste printing during PCB assembly.

Their main function is to remove residual solder paste from the stencil surface and apertures during printing. Keeping the stencil clean ensures uniform paste transfer. This reduces variations that can negatively affect print quality over time.

Why Stencil Contamination Builds Up During Printing

Stencil contamination is unavoidable in modern SMT production lines. During repeated printing cycles, excess solder paste gradually accumulates on the stencil surface and inside fine apertures. This is especially common in high-density, fine-pitch designs.

If residues are not removed effectively, they interfere with paste release. This often causes gradual printing instability rather than immediate failure. Increasing cleaning frequency alone does not fully solve the problem. The wiping material must consistently remove residues from critical apertures.

Material Design Behind Stencil Cleaning Rolls

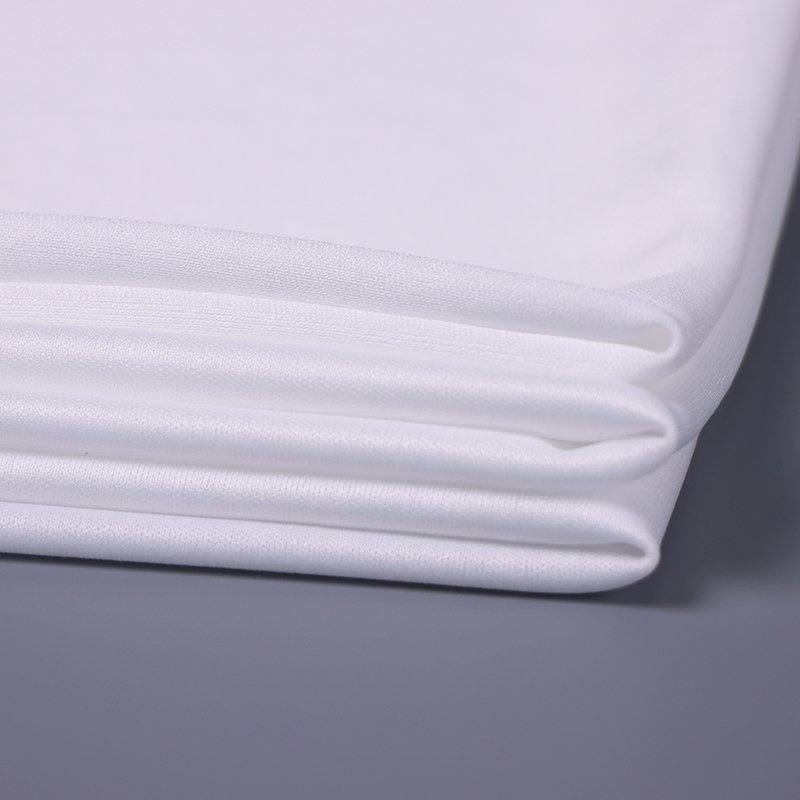

The performance of SMT stencil cleaning rolls depends largely on the wiping fabric. Premium-grade rolls use engineered fabrics rather than ordinary paper or simple nonwoven material. These fabrics withstand repeated mechanical action while maintaining stable cleaning.

High-performance wiping fabrics are developed for demanding stencil cleaning. They are made from a blend of polyester and cellulose. The fibers are bonded into a uniform, abrasion-resistant structure. This fabric combines mechanical toughness with high absorbency. It removes solder paste effectively without breaking down or generating particles.

The fabric surface provides numerous micro-cavities that capture and hold solder paste residues. This feature is crucial for cleaning lead-free solder paste, which is stickier and harder to remove. Materials without proper surface structure may smear paste instead of removing it.

Premium wiping fabrics are virtually lint-free. This minimizes secondary contamination on the stencil surface. In practice, absorbency, surface structure, durability, and low particle generation distinguish standard rolls from premium ones. Over long production runs, these differences affect cleaning consistency and SMT printing stability.

ESD Considerations in SMT Environments

Stencil cleaning is not a direct electrostatic discharge event. However, uncontrolled static during wiping can introduce risk in sensitive SMT environments. Premium stencil cleaning rolls are often designed with ESD considerations. This aligns with common electronics manufacturing requirements.

Proper static control contributes to a stable and predictable cleaning process. It is especially important in high-volume lines handling sensitive components.

How Cleaning Quality Influences Printing Defects

Effective stencil cleaning directly impacts printing quality. Inconsistent or incomplete residue removal can cause defects such as smearing, bridging, solder balls, and insufficient solder deposits.

Stable cleaning performance supports consistent paste transfer. It also reduces process drift, improves repeatability, lowers rework rates, and increases overall yield. These benefits occur even when other process parameters remain unchanged.

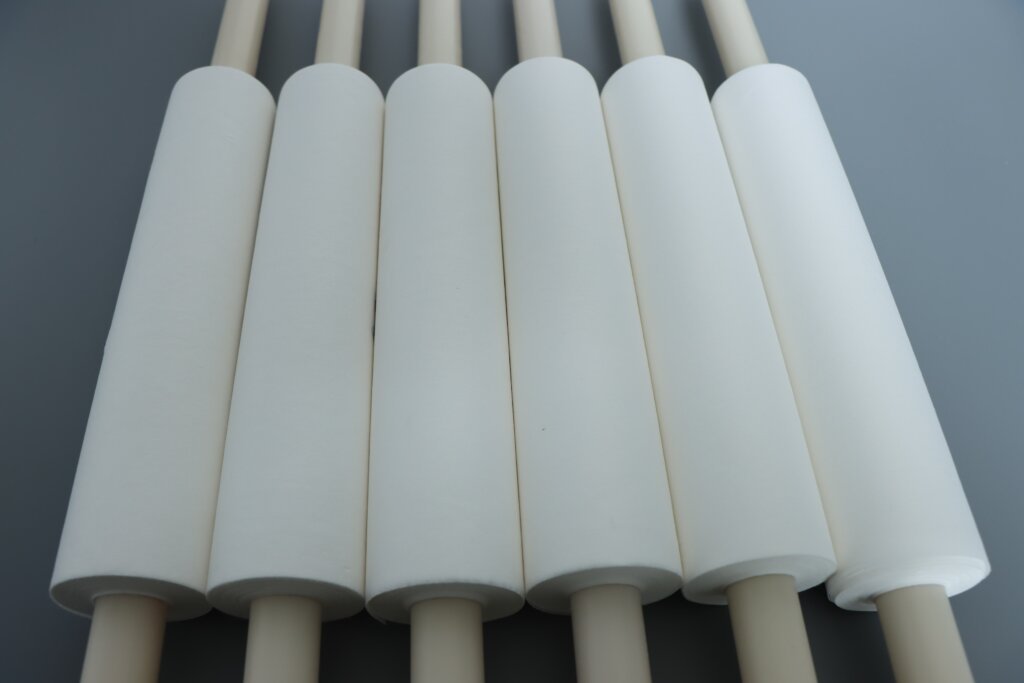

Printer-Specific Size and Core Requirements

Stencil printer compatibility is critical for cleaning roll performance. Different printer brands and models require specific roll widths, core diameters, and tube designs. These ensure proper installation and vacuum operation.

Using incompatible or poorly manufactured rolls may cause feeding issues, uneven wiping pressure, or inconsistent cleaning. Variations in roll quality between batches can introduce subtle inconsistencies that complicate process control.

Ready for Reliable Stencil Cleaning?

Our premium SMT stencil cleaning rolls are compatible with a wide range of stencil printers. They can be customized in material composition, roll width, and length to meet your specific production requirements. Ensure stable paste printing and reduce defects with rolls engineered for both performance and flexibility.

Our team can help you select the right rolls for your printers and provide tailored solutions for your production line.