For industries such as pharmaceuticals, electronics manufacturing, and cleanroom operations, consumables like wipes, gloves, and apparel are not just operational necessities—they are compliance-critical items. However, rising costs are forcing procurement and operations teams to look for savings. The challenge: reducing expenses without breaching industry regulations like ISO 14644, GMP, or AQL standards.

The truth is, cost reduction and compliance can coexist. With a data-driven approach to sourcing, product selection, and usage practices, companies can save 10–25% annually while maintaining the highest quality standards.

Understanding Compliance Requirements

Before any change in procurement policy, you must map out your compliance framework:

-

Cleanroom Standards (ISO 14644) – Define permissible particle counts; impact wipe fabric selection, packaging, and apparel.

-

Pharmaceutical GMP – Requires validated cleaning procedures, traceable materials, and documented supplier qualifications.

-

AQL Standards for Gloves – Define defect rates (e.g., AQL 1.5 = max 1.5% defective rate), critical in sterile manufacturing.

Non-compliance risks include halted production, regulatory fines, rejected product batches, and reputational loss—costs that can far exceed potential savings.

Identifying High-Cost Consumables

Your biggest savings opportunities often lie in a few categories:

-

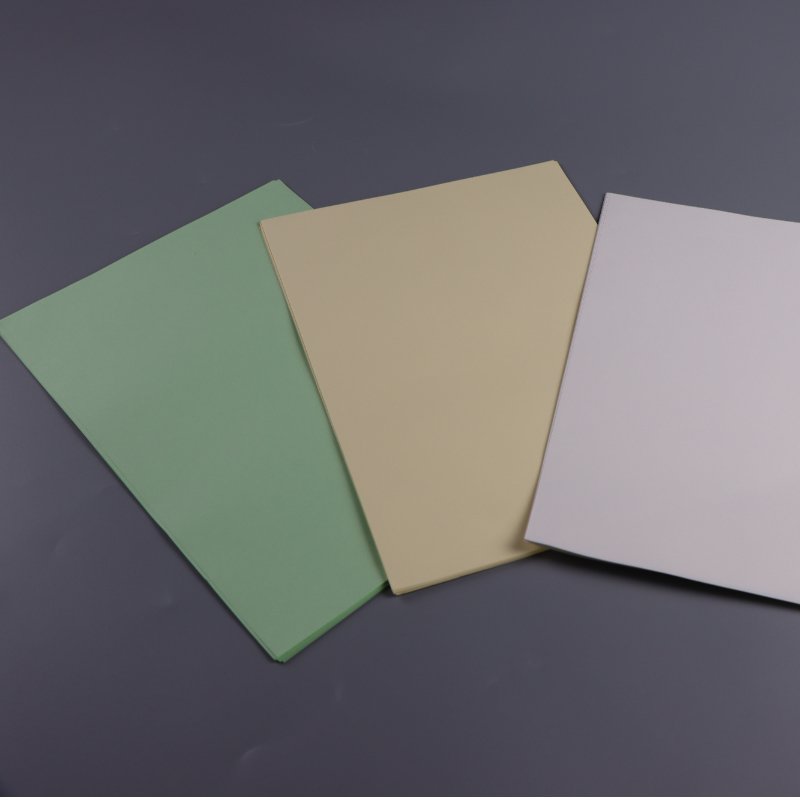

Cleanroom wipes – Polyester knit, microfiber, presaturated wipes.

-

Disposable gloves – Nitrile, latex, ESD-safe.

-

Cleanroom apparel – Coveralls, hoods, shoe covers.

-

ESD-safe packaging – Anti-static bags, barrier pouches.

Cost drivers include:

-

Premium-grade materials for compliance

-

Low-volume or custom SKUs

-

High logistics and import duties

-

Short shelf-life requiring frequent reorders

Tip: Conduct a 12-month spend analysis to identify the top 10 consumable SKUs by cost.

Cost Reduction Strategies Without Risking Compliance

1. Vendor Consolidation

Fewer vendors = higher volume discounts, reduced freight costs, and easier compliance audits.

Example: A semiconductor plant reduced wipe costs by 15% by consolidating from 5 vendors to 2 ISO-certified suppliers.

Caution: Always qualify at least two approved vendors to prevent supply disruptions.

2. Product Standardization

Reduce SKU variety to increase purchasing leverage.

Example: Switching from three types of Class 100 wipes to a single 105 gsm polyester knit wipe that met all cleanliness tests (LPC < 0.5 million particles/m²).

3. Bulk Purchasing & Inventory Management

Buying larger lots can lower unit pricing by 8–12%. Combine with inventory control to avoid overstock and expired products.

Pro Tip: Implement a barcode inventory system to track shelf-life and batch numbers for compliance.

4. Technical Evaluation of Alternatives

Identify lower-cost substitutes that still pass all compliance tests:

-

Wipes – Lower-gsm polyester (90–105 gsm) instead of ultra-heavyweight (120 gsm) for non-fluid-intensive applications.

-

Gloves – Switch from AQL 1.0 to AQL 1.5 for non-sterile handling tasks.

Validation Process:

-

Test LPC (Liquid Particle Count), NVR (Non-Volatile Residue), and solvent compatibility.

-

Use a 5–10 sample batch for performance benchmarking before approval.

5. Training to Reduce Waste

Educate staff on proper usage:

-

Fold wipes into quadrants to maximize surface area.

-

Use measured dispensing for solvents.

-

Adopt glove change intervals based on task risk, not arbitrary time frames.

Real-World Case Studies

-

Pharma GMP Facility – Trained 80 staff on wipe folding technique, reducing wipe usage by 22% annually (~USD 14,000 savings).

-

Electronics Assembly Plant – Switched to alternative ESD-safe pouches, cutting packaging costs by 18% without ESD failures.

-

Semiconductor Cleanroom – Standardized on one wipe type and reduced glove wastage, saving USD 62,000/year while passing all Class 4 particle tests.

Implementation Checklist

-

Audit top consumable spend categories.

-

Map compliance specs for each category.

-

Source at least two compliant alternatives.

-

Conduct in-house validation (LPC, NVR, ESD tests).

-

Run a controlled trial.

-

Roll out and monitor defect rates and savings.

FAQ

Q1: Can cheaper consumables still meet ISO or GMP standards?

Yes, if they pass required particle, residue, and solvent compatibility tests. Validation is essential.

Q2: What’s the safest way to test alternatives?

Run small-batch trials under real operating conditions, with QA sign-off before full implementation.

Q3: How often should consumable strategies be reviewed?

At least once per year, or whenever major regulation updates occur.

Next Steps

Reducing consumable costs is not about cutting corners—it’s about making smarter choices. With supplier consolidation, product standardization, technical validation, and targeted training, you can save 10–25% annually without losing compliance.

Contact our engineering team to discuss how we can help you implement a compliance-first cost-saving program for your cleanroom or manufacturing facility.