Jiangsu Province,China

24/7 Customer Service

WhatsAPP/Wechat

Sterile Cleanroom Wipes offer the highest sorptive capacity of any sealed edge wipe available. It is manufactured using two layers of knitted polyester fabric that are laminated together to form a stronger, more adsorbent wipe. Additional fluid is captured within the quilted pockets between the fabric layers, increasing the sorbent capacity. it has more than twice the adsorbent capacity of a single layer wipe.

Technical parameter:

| Parameter | Description |

| Material Composition | 100% Continuous Filament Knit Polyester |

| Wipe Construction | Two-ply Pinsonic Construction with Diamond Pattern |

| Edge Sealing | Ultrasonically Sealed Edges |

| Sorptive Capacity | Over twice the absorbency of single-layer wipes |

| Cleanroom Class | Laundered and Packaged in ISO Class 4 (Class 10) Cleanroom |

| Application Environment | Suitable for ISO Class 3 and higher environments |

| Primary Use | Critical processing applications, spill control, print roll cleaning |

| Packaging | Sterile, cleanroom-ready packaging |

| Absorbency | High sorbency due to quilted pockets between fabric layers |

| Contamination Control | Designed to reduce fiber shedding and particle contamination |

2-ply Cleanroom Wiper

Key Attributes

• 100% continuous filament knit polyester

• Two-ply pinsonic construction with unique diamond pattern

• Ultrasonically sealed edge for reduced fiber contamination

• Laundered and packaged in ISO Class 4 (Class 10) cleanroom

Did We Answer Your Question?

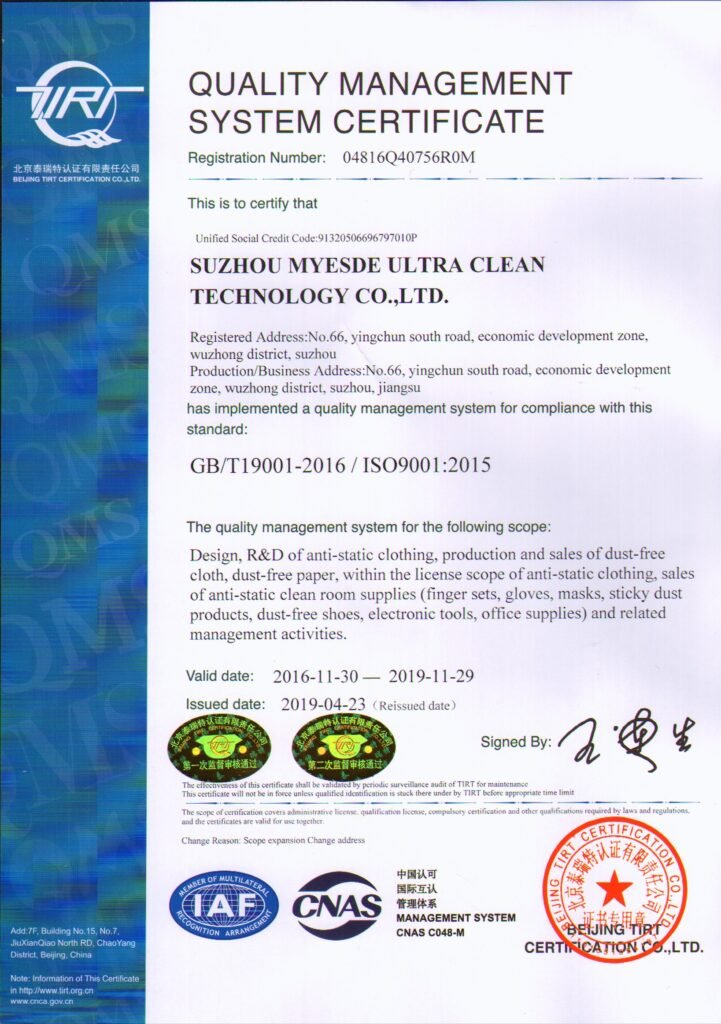

Suzhou Myesde Ultra Clean Technology Co.,LTD

Building 5, Wenyuan Industrial Park, Dongwu South Road, Wuzhong District,

Suzhou, China

Tel / WhatsApp / Wechat: +86-137-7631-4975

E-mail: info@cldzcl.com

Copyright © 2025. Suzhou Myesde Ultra Clean Technology Co.,LTD

We’re ready to provide fast, knowledgeable support.