In the world of optical lens cleaning—whether in camera manufacturing, laser optics, telescopic instruments, or high-precision microscopes—cleanroom wipers play a critical role in maintaining clarity, preventing coating damage, and ensuring long-term optical performance. Two materials dominate the market: microfiber and polyester wipers. While both are considered cleanroom-safe, their effectiveness varies depending on the cleaning requirements, sensitivity of the lens, and the types of contaminants involved.

This article presents a comprehensive, technical, and practical comparison of microfiber and polyester wipers, examining their structural differences, performance factors, and optimal applications in optical environments.

Understanding the Materials: What Are They Made Of?

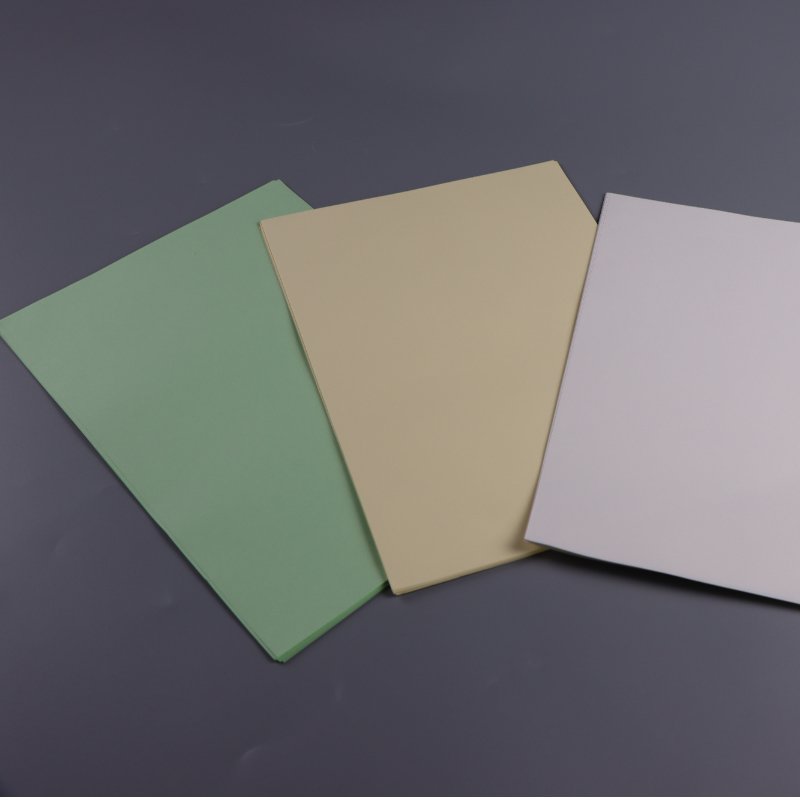

Polyester wipers are typically made of continuous filament polyester yarns woven into a tight, consistent structure. These wipers are hydrophobic, thermally stable, and generate low levels of particles. Polyester’s key advantages are its structural integrity, abrasion resistance, and compatibility with a wide range of solvents.

Microfiber wipers, in contrast, are made from split conjugated fibers, commonly a blend of polyester and polyamide (nylon). Through a specialized split fiber process, a single fiber is divided into dozens of microscopic strands, dramatically increasing the surface area and the number of capillary channels. This structural advantage significantly enhances microfiber’s absorbency and its ability to attract and trap particles through van der Waals forces and capillary action.

Why Fiber Structure Matters in Lens Cleaning

When cleaning a high-value optical surface, the goal is to remove particles without leaving residues or causing scratches. Fiber diameter, density, and softness all influence performance.

-

Polyester fibers have relatively smooth, cylindrical surfaces. They tend to push or drag particles rather than trap them. This increases the risk of abrasion when removing larger particles like silica dust or metallic flakes.

-

Microfiber is engineered for delicate surfaces. The multi-angled split structure creates microscopic “hooks” that gently lift and hold contaminants. This allows for single-pass cleaning, reducing friction and minimizing the risk of micro-scratches on AR coatings or precision-ground lenses.

Moreover, microfiber wipers generally have higher absorbency, which helps when wiping volatile solvents like IPA or lens-safe cleaning fluids. Their faster drying rates also reduce residue formation.

Lint-Free Performance: Which Material Is Cleaner?

For cleanroom optical applications, lint control is non-negotiable. Even a few stray fibers can compromise calibration or damage coatings.

-

Laser-sealed polyester wipers can deliver extremely low levels of particle shedding, especially when cut and sealed under controlled conditions. However, due to the fiber’s round structure, the edges may still fray under mechanical stress.

-

Ultrasonically cut microfiber wipers, despite having more complex fibers, can achieve comparable or better lint performance. The split fibers lock in particles internally, which reduces airborne fiber shedding during wiping.

That said, microfiber wipers tend to trap more contaminants than polyester wipers. If reused improperly, this can lead to the redistribution of particles. Therefore, microfiber wipers are best used as single-use tools in cleanroom optical applications.

Solvent Compatibility and Chemical Resistance

Polyester is highly resistant to a wide variety of cleaning agents, including isopropyl alcohol, acetone, and ketones. This makes it suitable for applications requiring aggressive solvents to remove adhesives or dried organics.

Microfiber, particularly those blended with nylon, may degrade or swell when exposed to strong acids or solvents. This limits their compatibility with some industrial-grade degreasers.

However, for lens-safe solutions, microfiber performs excellently. Its ability to absorb small amounts of solvent and distribute it evenly across a lens surface enhances both cleaning efficiency and drying time.

Applications in Optical Lens Environments

| Application Scenario | Preferred Wiper Type | Reason |

|---|---|---|

| Camera lens or smartphone optics | Microfiber | Gentle on coatings, high absorbency, non-abrasive |

| Laser lens or optical filters | Microfiber | Non-scratching, efficient dry/wet cleaning |

| Telescope mirror cleaning | Polyester | Larger surface area, strong mechanical stability, and solvent compatibility |

| Microscope lens maintenance | Microfiber | Low-residue, precision wiping |

| Optical fiber assembly lines | Polyester | High tensile strength, good solvent handling |

Cost, Durability, and Reusability

From a purchasing perspective, polyester wipers tend to be more economical and durable under physical stress. They are preferred when repeated wiping, folding, or soaking is necessary.

Microfiber wipers, while generally higher in unit cost, deliver better first-pass efficiency. They’re ideal for applications where a single precise wipe matters more than reuse.

In optical labs with strict contamination control protocols, the total cost of potential rework from lens damage far outweighs the price of the wiper, making microfiber the more cost-effective solution in high-risk zones.

Final Thoughts

Microfiber cleanroom wipers excel in ultra-delicate, coating-sensitive applications, delivering exceptional softness, high surface area, and superior particle entrapment. In contrast, polyester wipers offer robust durability, chemical compatibility, and cost-effectiveness, making them a reliable choice for less sensitive or more rigorous tasks.

In practice, many cleanroom protocols integrate both materials, with selection determined by the specific stage of the wiping process, the level of surface sensitivity, and the solvents involved.

As contamination control standards intensify across sectors such as semiconductors, biopharmaceuticals, aerospace, and precision manufacturing, the microfiber vs. polyester comparison has taken on broader significance.

-3.jpg)