Introduction

Maintaining a contamination-free environment is paramount in industries such as pharmaceuticals, electronics, and aerospace. Cleanroom swabs are essential tools designed to effectively remove particles, residues, and other contaminants without leaving any fibers or debris behind.

What Is A Cleanroom Swab?

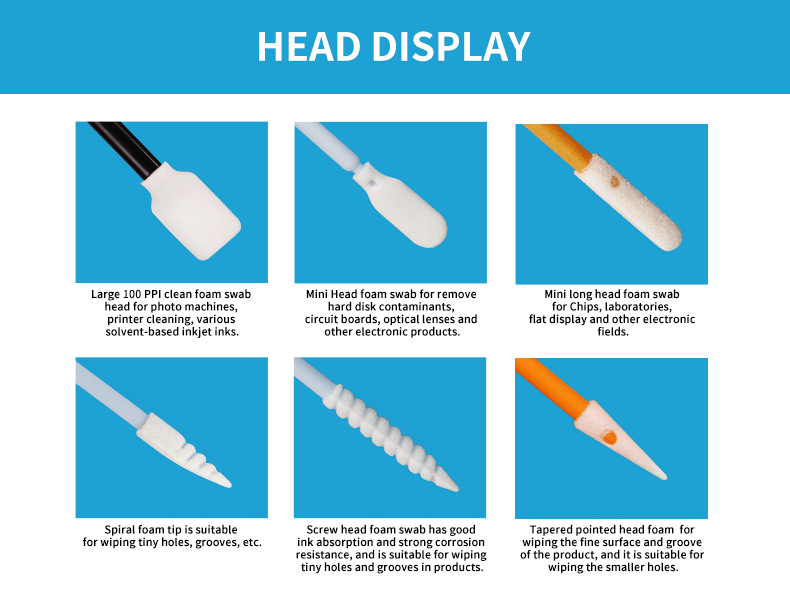

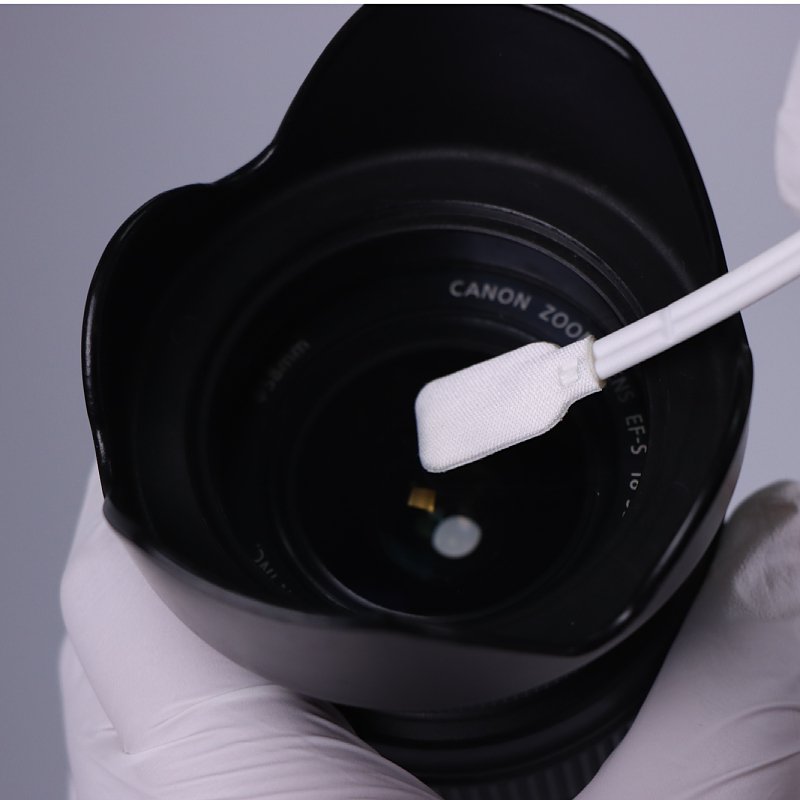

Cleanroom swabs are specialized cleaning tools used in controlled environments like cleanrooms, laboratories, and manufacturing facilities. They are constructed from materials such as foam, polyester, or microfiber, engineered to minimize particle generation, ensuring they do not introduce contaminants into critical environments.

How Does Cleanroom Swab Work in Contamination Control?

Cleanroom swabs function by physically removing contaminants from surfaces through their specially designed tips, which can trap and hold particles effectively. They are often used in conjunction with cleaning agents or solvents to enhance their cleaning efficacy.

Applications of Cleanroom Swab Across Industries

1. Semiconductor Industry

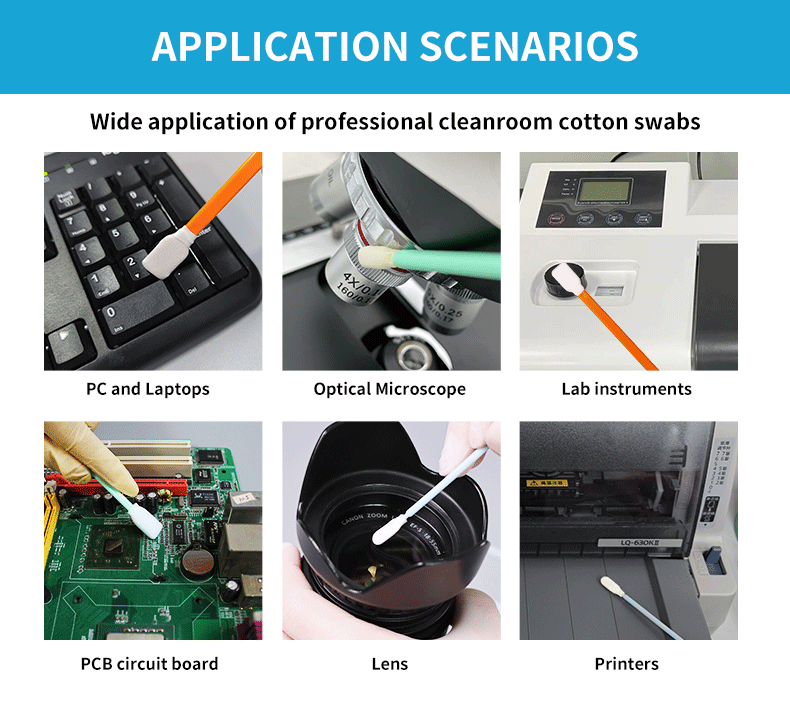

In semiconductor manufacturing, even the smallest particle can lead to defects. They are used to clean wafers, photomasks, and precision instruments, ensuring the removal of contaminants that could compromise product quality.

2. Pharmaceutical and Biotechnology

Maintaining cleanliness is critical in pharmaceutical and biotech industries. Cleanroom swab is used for cleaning vial septa, cuvettes, ampoules, and other critical areas, preventing cross-contamination and maintaining product sterility.

3. Electronics Manufacturing

In electronics, clean room swabs are employed to clean printed circuit boards (PCBs), connectors, switches, and other components, ensuring that no contaminants compromise the performance and reliability of electronic devices.

4. Aerospace and Defense

Clean room swabs are used in the aerospace industry for cleaning critical components such as fuel injectors, sensors, valves, and other precision parts, ensuring reliable and safe operation.

5. Medical Device Manufacturing

During the manufacturing of medical devices, clean room swabs are utilized to ensure proper cleanliness and quality of the products, preventing contamination that could affect device performance.

Best Practices for Using Clean Room Swab

- Proper Handling: Always handle swabs with clean gloves to prevent contamination.

- Compatibility: Ensure that the swab material is compatible with the cleaning agents or solvents being used.

- Storage: Store swabs in a temperature-controlled and humidity-regulated environment to maintain their effectiveness.

- Regular Inspection: Regularly inspect swabs for any signs of damage or contamination before use.

-8.jpg)

Conclusion

Cleanroom swabs are indispensable tools in maintaining the cleanliness and integrity of controlled environments across various industries. By effectively removing contaminants without introducing new ones, they play a crucial role in ensuring product quality and compliance with industry standards.

Blog Keywords: Cleanroom swabs, contamination control, cleanroom applications, cleaning tools, industry standards