Cleanroom wipers may look simple, but their performance depends on measurable technical indicators that directly affect production outcomes. Fibers, particles, non-volatile residues (NVR), metallic ions, and sorbency characteristics determine whether a wiper is suitable for sensitive environments. This guide provides a practical overview of the main test methods, how to interpret results, and what buyers should focus on when selecting cleanroom wipers.

Why Testing Matters

The performance of a cleanroom wiper cannot be judged by appearance alone. Even materials that look smooth can shed fibers or leave residues that impact production. Industries such as semiconductors, flat-panel displays, medical devices, optics, and biopharmaceuticals require specific performance levels for their processes.

Understanding test parameters helps engineers and procurement teams:

-

Choose materials suitable for their application

-

Reduce contamination risk

-

Ensure stable and consistent cleaning performance

The most common categories of evaluation are:

-

Cleanliness: fibers, liquid-borne particles, airborne particles

-

Sorbency: capacity, efficiency, absorption rate

-

Purity: non-volatile residue, metallic ions

Cleanliness Testing

Cleanliness is an indicator of how many particles or fibers a wiper will release during actual use. It is typically divided into fiber release, liquid-borne particles, and airborne particles.

1 Fiber Release

Fiber release measures how many fibers detach from a wiper under controlled conditions. Fibers ≥100 µm are counted after the wiper is agitated in water.

-

Test method: A wiper is washed for five minutes in water using a biaxial or orbital shaker. Released fibers are captured on a membrane and counted under a microscope. Results are expressed as fibers per square centimeter.

-

Importance: High fiber release can cause contamination on wafers, lenses, or coatings.

Impact by application:

| Application | Fiber Requirement | Notes |

|---|---|---|

| Semiconductor | Very low | Prevents yield loss |

| Optics / Lenses | Very low | Avoids visible defects |

| Medical Device | Moderate | Fiber shedding less critical |

| Industrial | Low to moderate | Acceptable if not touching sensitive surfaces |

For high-precision processes, choose polyester knit or microfiber wipers with low fiber counts. Avoid high-cellulose blends.

2 Particles

Particles are released when a wiper is submerged and agitated in water.

-

Test method: A liquid-borne particle counter tallies particles ≥0.5 µm. Results are normalized per square centimeter.

-

Importance: Particles can settle on sensitive surfaces, causing defects or reducing product reliability.

Industry relevance:

| Industry | Requirement | Notes |

|---|---|---|

| Semiconductor | Very low | Critical for wafer production |

| LCD / FPD | Low | Prevents mura on screens |

| Medical Device | Moderate | Reduces contamination risk |

| Industrial Cleaning | Low to medium | Acceptable levels |

Check test results per cm² rather than relying solely on “Class 1000” labels.

3 Airborne Particles (Helmke Drum Test)

The Helmke Drum simulates particle release when wipers are handled or moved.

-

Test method: Ten wipers are tumbled in a rotating drum. Airborne particles are counted per cubic foot of air.

-

Importance: Wipers may pass liquid particle tests but still release airborne particles during folding or wiping.

| Application | Airborne Requirement |

|---|---|

| Semiconductor | Very low |

| Optical / Lens | Low |

| Biopharma | Moderate |

| Industrial | Acceptable |

If your process involves dry wiping, prioritize wipers with low airborne particle release.

Sorbency Testing

Sorbency determines how effectively a wiper absorbs liquids. There are three key measurements: capacity, efficiency, and rate.

1 Capacity

Capacity measures the total volume of liquid a wiper can hold.

-

Test method: Saturate a sample with liquid, wait one minute, then weigh. Expressed in milliliters per square meter.

-

Importance: High capacity helps with large spills and solvent-heavy cleaning.

2 Efficiency

Efficiency measures absorption relative to material weight, expressed as milliliters per gram.

-

Importance: Allows comparison of raw materials. Microfiber typically shows higher efficiency, while cellulose blends may have high capacity but lower efficiency.

3 Absorption Rate

Absorption rate measures how quickly the wiper absorbs liquid, expressed in seconds.

-

Importance: Fast absorption is needed for IPA wiping or solvent cleaning. Controlled absorption is preferred for optics to avoid streaks.

Sorbency comparison table:

| Material | Capacity (mL/m²) | Efficiency (mL/g) | Rate (s) | Suitable Use |

|---|---|---|---|---|

| Microfiber | Medium | High | Fast | Optical cleaning, IPA wiping |

| Polyester Knit | Medium | Medium | Moderate | Semiconductor, general wiping |

| Cellulose Blend | High | Low | Moderate | Large spill cleanup, general cleaning |

Match absorption characteristics to your process, not just pick the highest capacity.

Purity Testing

Purity determines chemical cleanliness. Two main tests are Non-Volatile Residue (NVR) and metallic ions.

1 Non-Volatile Residue (NVR)

-

Test method: Extract wiper in DI water and IPA, evaporate, and weigh residue. Expressed in g/m².

-

Importance: Residue can affect surface energy, coating adhesion, and device reliability.

2 Metallic Ions

-

Test method: Extract wiper in DI water, analyze with ion chromatography.

-

Monitored ions: Na⁺, K⁺, Cl⁻, Ca²⁺, Mg²⁺

-

Importance: Excess ions can cause corrosion, short circuits, or film defects.

Application relevance:

| Industry | NVR Requirement | Ionic Requirement |

|---|---|---|

| Semiconductor | Very low | Very low |

| LCD / FPD | Low | Low |

| Optics | Low | Low |

| Medical Device | Moderate | Low |

| Industrial | Acceptable | Moderate |

Always request full NVR and ion data to assess chemical compatibility.

Material and Construction

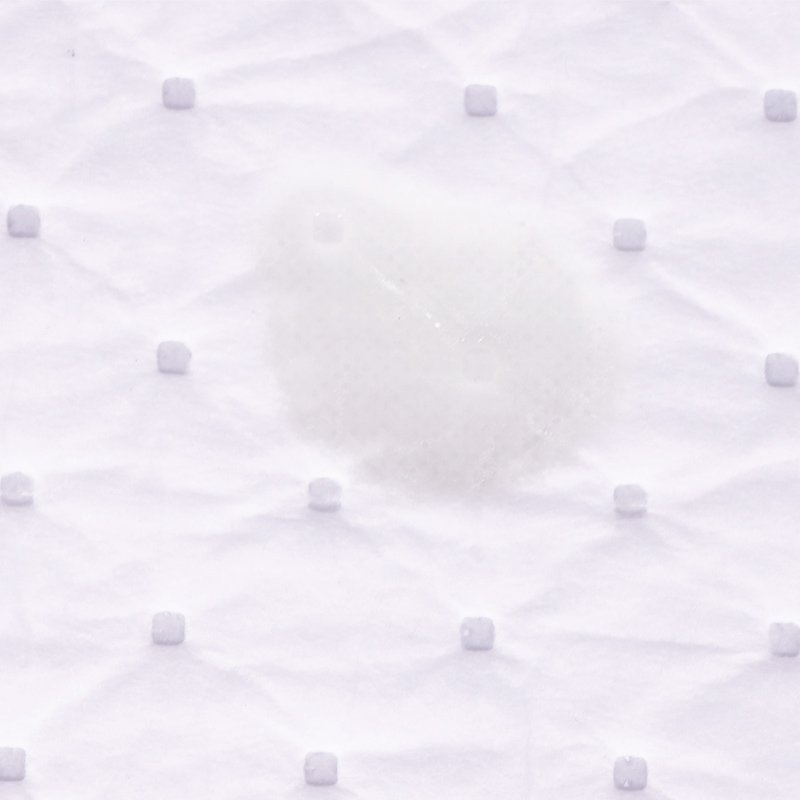

Material and edge treatment affect fiber release, particles, and sorbency.

-

Materials: Polyester knit, microfiber, cellulose/polyester blends, meltblown

-

Edge Sealing: Laser-cut, ultrasonic, or cold knife

-

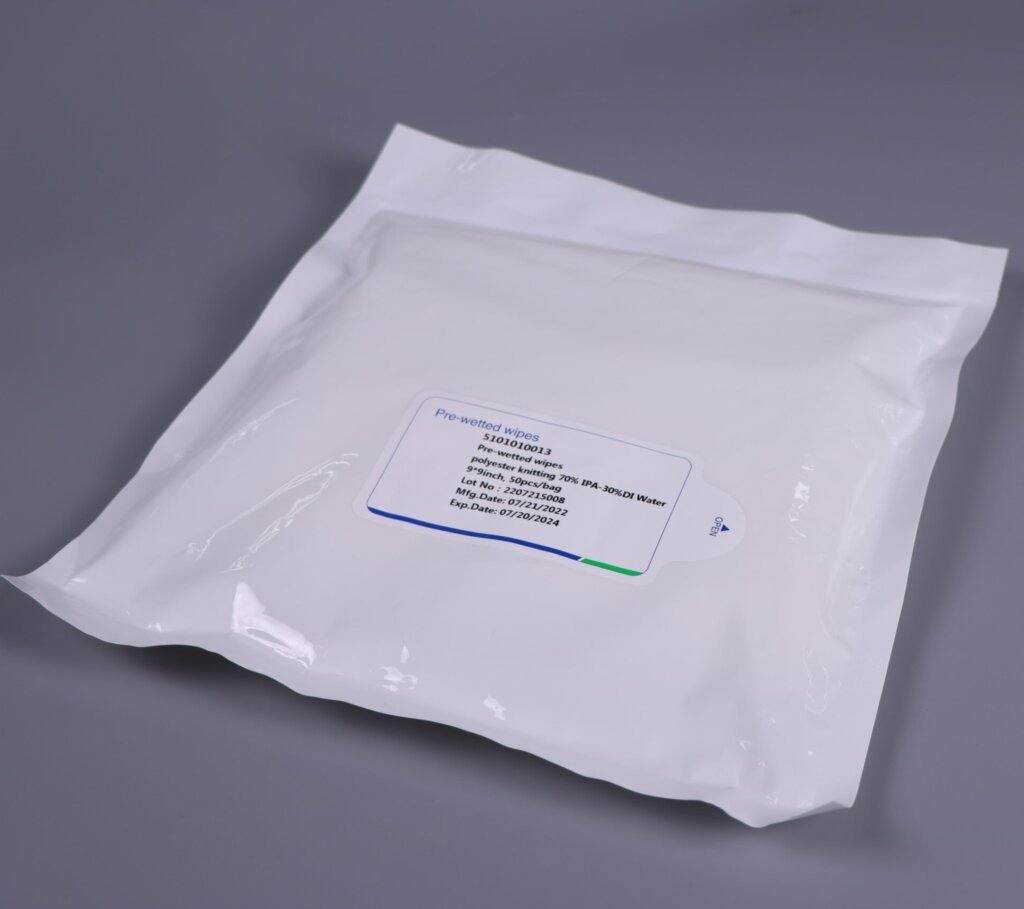

Packaging: Double-layer vacuum preserves cleanliness

For critical processes, prioritize laundered, laser-cut, or ultrasonic-cut microfiber wipers with proper packaging.

Matching Test Results to Applications

| Industry | Key Parameters | Recommended Materials |

|---|---|---|

| Semiconductor | Low fibers, low particles, low NVR & ions | Laundered polyester knit, microfiber |

| LCD / FPD | Low particles, low NVR | Microfiber, polyester/cellulose blend |

| Optics / Lenses | Low fibers, controlled sorbency | Microfiber |

| Medical / Biopharma | Moderate fibers, consistent absorption | Polyester, nonwoven blends |

| Industrial | Balanced performance, cost-effective | Polyester/cellulose blends |

How to Evaluate Supplier Test Reports

-

Compare results per cm² or per m², not by generic class

-

Ensure test conditions match IEST-RP standards

-

Review NVR, ion profile, sorbency data

-

Confirm packaging and handling conditions

-

Request multiple batches to verify consistency

Buyer checklist:

-

Fiber release (fibers/cm²)

-

Liquid-borne particles (particles/cm²)

-

Airborne particles (per cubic foot)

-

Sorbency (capacity, efficiency, rate)

-

NVR (g/m²)

-

Metallic ions (ppm)

-

Edge-cut method and packaging