Semiconductor manufacturing is an environment where even the smallest detail can make or break production. A single fiber on a wafer can cause a lithography defect. One electrostatic discharge can ruin a high-value die. And every additional particle increases the risk of costly yield loss.

To control these risks, fabs rely on cleanrooms operating at ISO Class 3–5, where airborne particles, static electricity, and chemical residues are strictly managed. Yet, what often goes unnoticed is how much this control depends on consumables—the everyday items that prevent contamination, protect delicate devices, and maintain compliance with ISO 14644 standards.

Here are the five essential cleanroom consumables every semiconductor fab needs, why they matter, and what happens if you get them wrong.

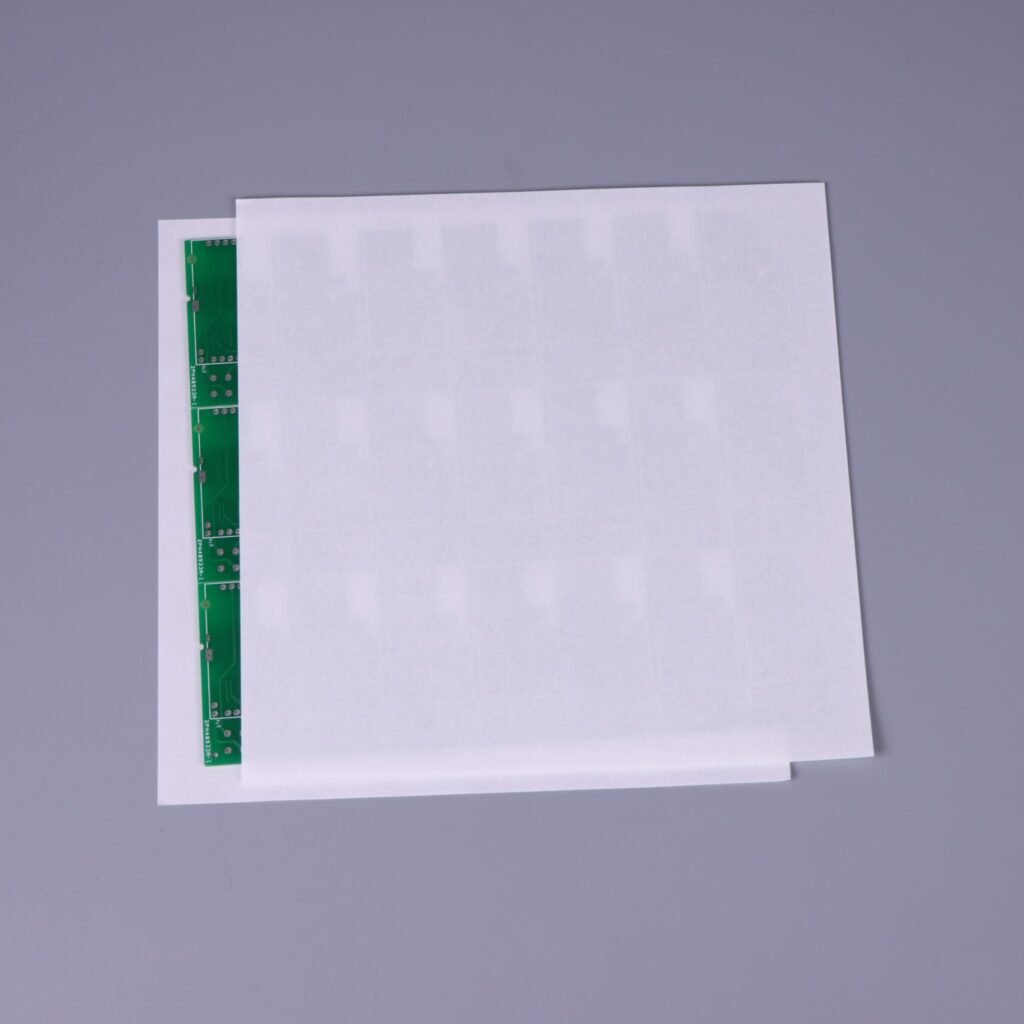

1. Cleanroom Wipes

Every wafer process, from photolithography to etching, demands a pristine surface. But here’s the reality: wafers travel through dozens of steps and tools, and contamination can happen anywhere—inside a chamber, on a reticle, or during carrier box handling.

Cleanroom wipes are more than just pieces of fabric. They’re engineered to leave zero fibers, resist solvent degradation, and minimize non-volatile residues (NVR). High-purity polyester knitted wipes dominate ISO Class 3–5 zones because they shed fewer particles and maintain integrity even when soaked with IPA or acetone.

The risk of choosing wrong? A cellulose blend wipe might seem cheaper, but its higher particle count can lead to killer defects. In one documented case, a 0.5 μm particle caused a critical failure in a 14 nm node wafer, triggering a batch rejection worth millions.

Best practice:

-

Use sealed-edge polyester wipes for photolithography and wafer cleaning.

-

For ultra-critical zones (mask shops, EUV lithography), consider microfiber wipes for superior particle retention.

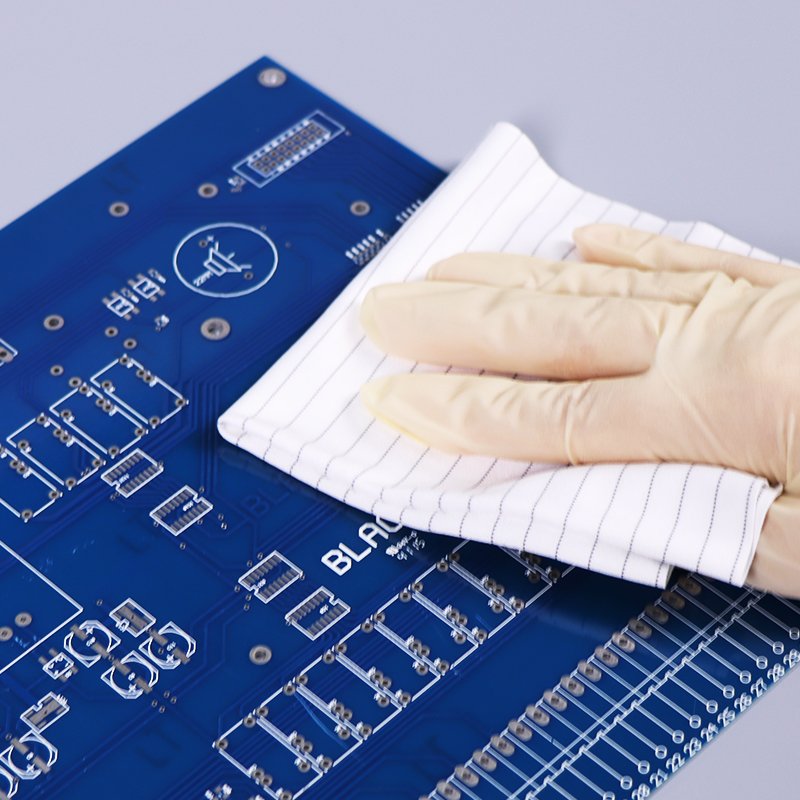

2. Gloves

Gloves are often viewed as simple PPE, but in semiconductor fabs, they serve two critical functions: contamination control and ESD protection. Bare hands release oils and particles that can ruin wafer surfaces, while uncontrolled static can destroy microchips before they’re even packaged.

Nitrile gloves have become the standard in fabs due to their low particle generation and solvent resistance. For areas handling sensitive dies, ESD-safe nitrile gloves add a conductive grid or polymer coating that dissipates static without compromising cleanliness.

Here’s what many overlook: powdered gloves are a disaster in cleanrooms. Residue from the powder can cling to wafer carriers, creating ionic contamination that interferes with etch processes.

Pro tip:

-

Specify gloves tested for surface resistivity (10⁶–10⁸ Ω) and low ion extractables.

-

Stock different sizes—ill-fitting gloves increase the risk of tears and particle release.

3. Adhesive Mats

Human traffic is the biggest contamination vector in any fab. Even after full gowning, shoes and trolley wheels carry particles that standard flooring can’t capture. That’s why tacky mats are stationed at every gowning area and material transfer point.

These mats work by trapping particles on multiple adhesive layers. A fresh layer ensures maximum capture efficiency, typically removing 95% of particles ≥1 μm from footwear. It sounds simple, but here’s the catch: many fabs fail to replace layers often enough, turning mats into contamination sources rather than barriers.

Placement matters too. A mat installed too far from the critical entry point allows particles to reattach. The best strategy? Multiple mats in series for high-traffic areas, with clear SOPs for layer replacement.

4. Presaturated Wipes and Swabs: Precision Cleaning Tools

When cleaning photomasks, reticles, or wafer carriers, consistency is everything. Mixing IPA with DI water manually introduces variability that fabs can’t afford. Presaturated wipes deliver controlled solvent application, ensuring uniform cleaning and reducing VOC exposure for operators.

Swabs serve a different role—reaching into tight corners of lithography equipment, vacuum chucks, and robotic arms where wipes can’t go. Foam-tipped swabs are great for solvent use, while polyester-tipped swabs excel in ultra-clean zones thanks to their lower particle release.

Skipping these? Expect contamination hotspots where your wipes can’t reach—and process engineers scrambling to explain yield dips.

5. ESD Garments and Shoe Covers

Particles aren’t the only threat; electrostatic discharge (ESD) silently wreaks havoc on semiconductor devices. The cost of an ESD event isn’t always immediate—it can show up as latent failures in the field, damaging your customer trust and your bottom line.

ESD-safe garments, typically made of polyester with a conductive carbon grid, control both particle shedding and static buildup. Paired with shoe covers featuring grounding strips, they maintain compliance with IEC 61340-5-1 standards for ESD protection.

Failing to enforce proper garment use is a compliance red flag during audits—and a ticking time bomb for product reliability.

What Happens When You Get It Wrong?

-

Yield Loss: One particle in the wrong place can trigger thousands of device failures.

-

Audit Failures: Annex 1 and ISO auditors will flag non-compliant consumables immediately.

-

Hidden Costs: A $5 saving on gloves can lead to millions in rework and downtime.

Final Thoughts

Semiconductor cleanrooms are high-stakes environments where perfection isn’t optional. The consumables you choose—wipes, gloves, mats, swabs, garments—aren’t trivial purchases. They’re the foundation of contamination control, ESD safety, and regulatory compliance.

The lesson is clear: choose wisely, standardize your processes, and never cut corners on critical consumables.

Looking for ISO Class 3–5 certified wipes, ESD-safe gloves, or presaturated cleaning solutions? Explore our full range of semiconductor-grade cleanroom products and request samples today.