About Us

A Leading Manufacturer of Cleanroom Wipes

Myesde Group

Founded as a specialist in cleanroom wipers, Myesde has expanded into a full range of contamination control and cleanroom consumables. With an in-house laboratory, standardized testing methods for cleanroom disposables, and comprehensive quality assurance systems, we ensure verified cleanliness, batch consistency, and process reliability for global distributors, wholesalers, and OEM partners serving regulated and high-precision industries.

What We Offer

Explore our key services designed to enhance your environment.

Cleanroom Consumables

High-performance consumables designed for contamination control in critical environments.

Human Protection

Comprehensive personal protection solutions for cleanroom and industrial safety.

Electrostatic Control

Reliable ESD control products to safeguard sensitive components and processes.

Environmental Purification

Integrated purification systems to maintain cleanroom air quality and integrity.

Mission

To Prevent Micro-Contamination and Empower High-Tech Industries.

Our Role in Cleanroom Operations

Provider of comprehensive equipment and consumables for cleanroom operation and maintenance.

Our Mission

Preventing Micro-contamination to Enable High-Tech Innovation.

Our Values

Focused on quality and continuous innovation

Team

Our team integrates R&D, production, and marketing, with deep industry experience and a strong commitment to quality. Our R&D and technical staff focus on innovation and product performance, while our production team ensures precision and cleanliness at every step. The marketing team understands customer needs and delivers responsive, professional support. Working together, we provide reliable cleanroom solutions trusted by clients worldwide.

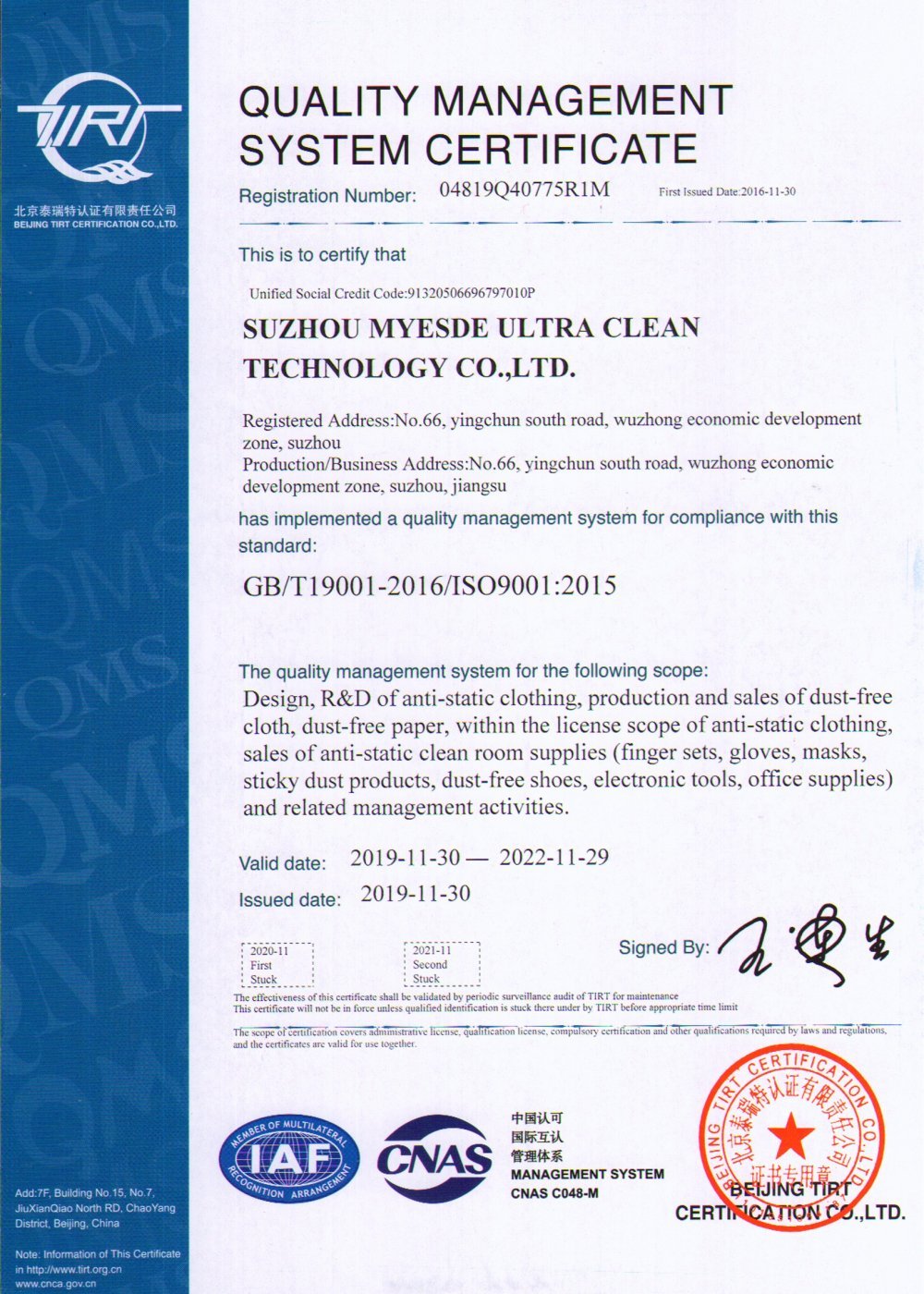

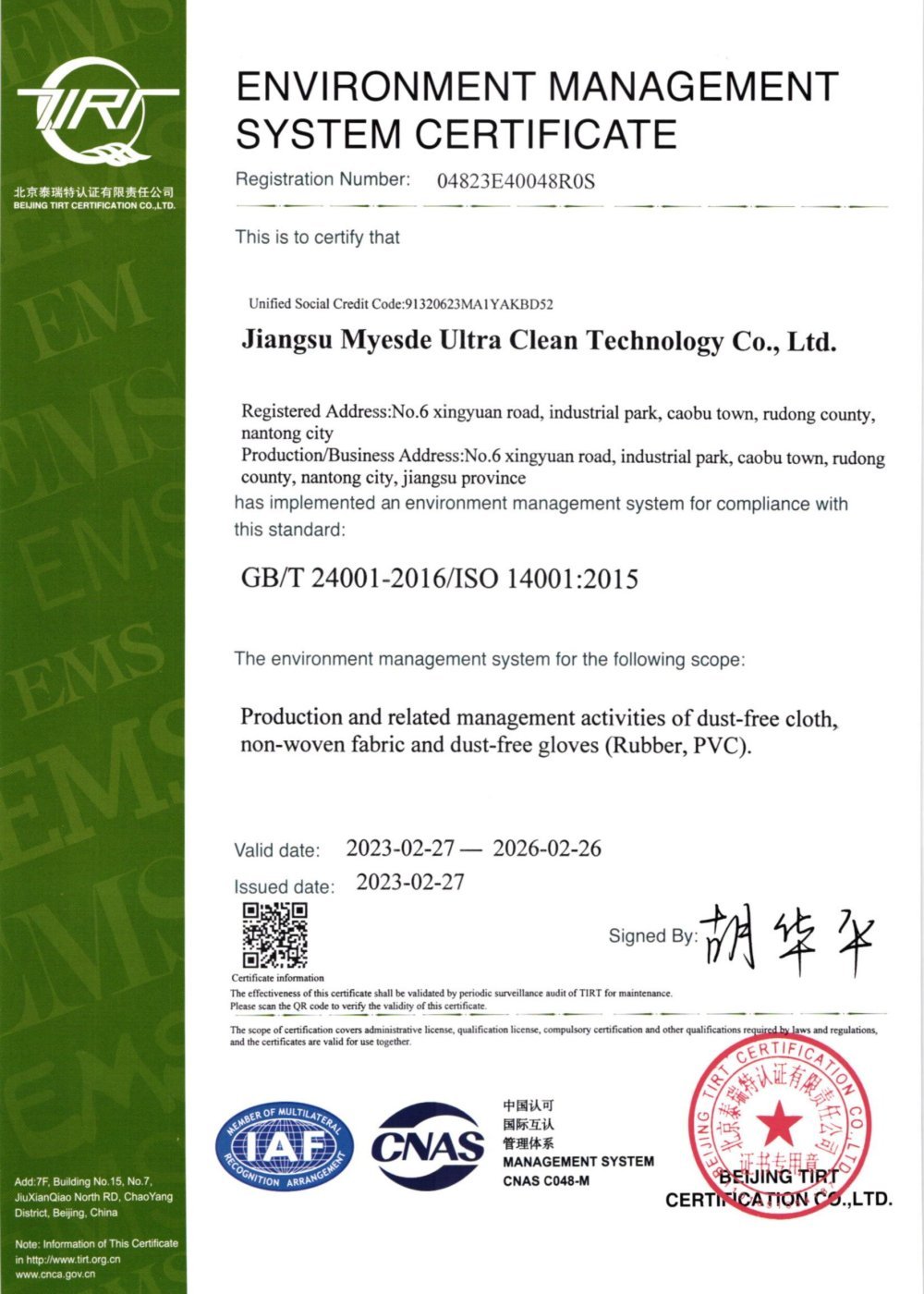

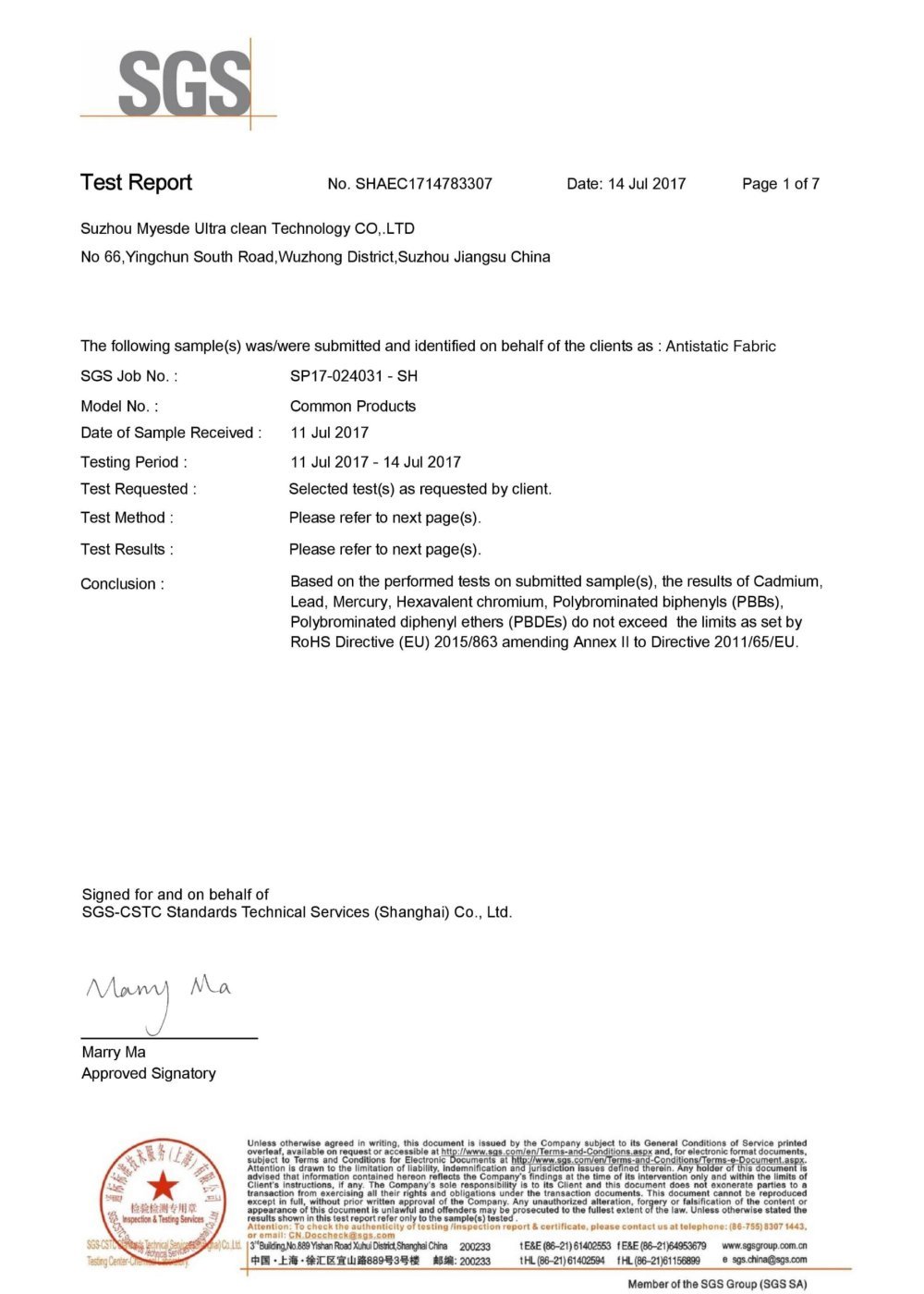

Certifications

Facilities

Nantong Factory

Suzhou Office

Vietnam Branch Office

High Quality Raw Material

ISO 4 ( Class 100 ) Cleanroom

Laboratory Testing

Advanced Equipment

Advanced Equipment

Advanced Equipment

Fully In-House Production

From Raw Materials to Final Packaging and Quality Testing.

AA-Grade Yarns

We Use Only Premium AA-Grade yarns, Free from Silicone Additives During Production.

Weaving Machine

With various types of knitting needles such as 28 needles, 38 needles, 42 needles, we can provide customers with different weaving styles.

Cleanig & Dyeing

The use of DI water and non-ionic surfactant for water washing treatment, providing the fabric of clean & low ion pollution and low NVR

Faric Packing

The fabric is packaged with double PE film to prevent outside dust from falling on the fabric

Cutting

We have 10 sets laser machine, 8 sets ultrasonic machine.

Laundering & Drying

Using 18M ultra-pure water to do laundry, in order to ensure the cleanliness of the product.

Inspection & Packing

Visual inspection process and packing is completed in ISO class 4/5 cleanroom.

Finished Wipes

The whole quality management system control to ensure the product stability and traceability.

Moments with Our Partners