Industry Background

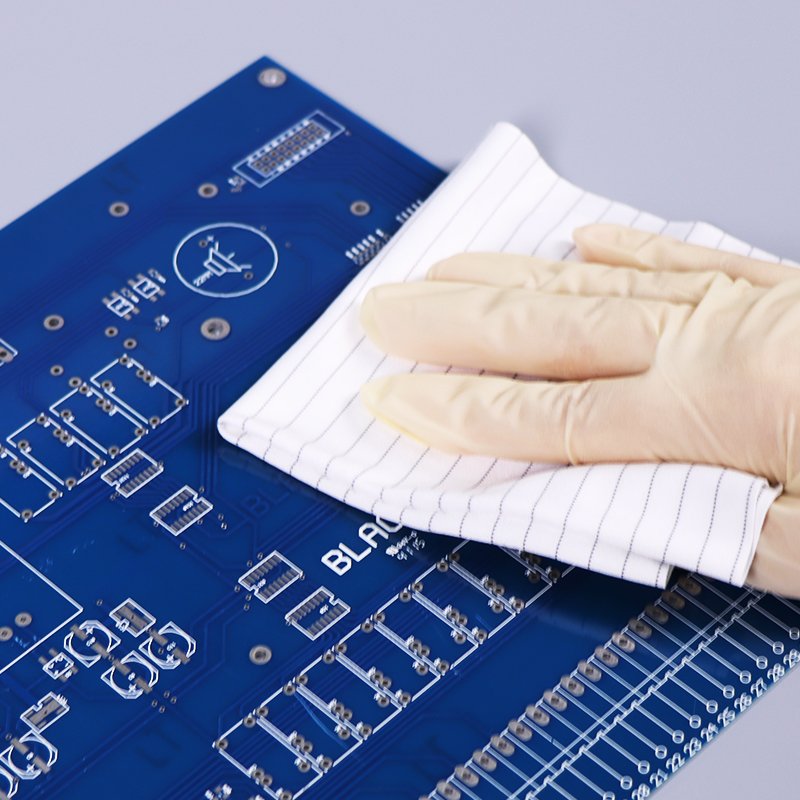

Cleanroom wipers are essential in industries where contamination control is critical. These include semiconductor manufacturing, pharmaceutical production, biologics, life sciences, and aerospace. In these sectors, even minor contamination can compromise product quality, reduce yields, or create safety risks.

Cleanrooms are constructed to meet strict ISO classifications. ISO Class 1–5 environments are typical for semiconductor fabrication, while pharmaceutical and biologics processes may require Class 3–7 cleanrooms. Maintaining these conditions requires strict control over airborne particles, surface residues, and chemical contamination.

Wipers are a primary tool for contamination control. They directly contact surfaces, instruments, and equipment. Any residues left on a wiper, including non-volatile residues (NVR) or metallic ions, can transfer to critical surfaces. Understanding wiper purity is therefore essential for operational success.

NVR and Ionic Contamination

Non-Volatile Residues (NVR) are substances that do not evaporate under normal conditions. They may include oils, surfactants, detergents, or chemical residues from manufacturing and laundering.

Metallic ions are another common source of contamination. Typical ions include sodium (Na⁺), potassium (K⁺), calcium (Ca²⁺), magnesium (Mg²⁺), and iron (Fe³⁺). These ions can originate from fibers, chemical additives, laundering processes, or even water used in manufacturing.

High levels of NVR or ionic contamination can have significant consequences:

-

Semiconductors: Residues may affect photolithography and chemical deposition, reducing wafer yields.

-

Pharmaceuticals: Ionic contamination can react with active pharmaceutical ingredients, impacting drug safety and stability.

-

Optics and precision instruments: Even trace residues can alter lens coatings, sensor calibration, or component assembly.

Therefore, controlling these contaminants is a critical aspect of cleanroom operations.

Contamination Control Strategies

Several strategies help minimize NVR and ionic contamination in cleanroom wipers:

High-Purity Materials

-

100% continuous filament polyester is widely used due to low NVR and minimal ionic content.

-

Microfiber or microdenier polyester yarns reduce particle release and surface abrasion.

ISO-Classified Laundering

-

Cleanroom laundered wipers undergo processes in ISO Class 4–5 facilities.

-

Laundering removes residual oils, chemicals, and ions.

-

Specialized rinsing and drying processes ensure minimal NVR and ionic residues.

Packaging and Handling

-

Double-layer vacuum packaging protects wipers from contamination.

-

Handling with gloves and cleanroom protocols prevents recontamination.

Material Selection and Design

-

Knitted wipers may have lower NVR due to tighter filaments and controlled knitting processes.

-

Woven or spunlace nonwoven wipers are suitable where absorbency and mechanical strength are prioritized.

By combining material selection, laundering, and handling protocols, contamination risks can be substantially reduced.

Measurement Methods

NVR Testing

-

Wipers are extracted using deionized water or solvents such as 2-propanol.

-

Extractables are measured in grams per square meter (g/m²).

-

Typical high-purity wipers have NVR values below 0.2–0.5 g/m².

-

Lower values indicate cleaner surfaces and reduced risk of transferring contaminants.

Ionic Contamination Testing

-

Ions are extracted in deionized water under controlled conditions.

-

Concentrations are measured using ion chromatography.

-

Results are expressed in parts per million (ppm).

-

Typical targets for high-purity wipers: Na⁺ < 0.2 ppm, K⁺ < 0.1 ppm, Fe³⁺ < 0.05 ppm.

Standards

-

Testing follows IEST-RP.CC004.4 Section 8.1–8.2.

-

NVR and ionic tests are conducted per square meter to allow comparison across different wiper sizes.

These tests allow manufacturers and end-users to quantify purity and select wipers for sensitive processes.

Application-Specific Considerations

Different industries prioritize NVR and ionic contamination differently:

Semiconductor Manufacturing

-

Photolithography and deposition processes are sensitive to residues.

-

NVR can leave organic films on wafers, causing defects or pattern distortions.

-

Metallic ions can form conductive paths, leading to short circuits.

-

Therefore, wipers with NVR < 0.3 g/m² and ions < 0.2 ppm are preferred.

Pharmaceutical and Biologics

-

APIs and biologics can react with residues or ions.

-

Sodium or potassium ions may catalyze degradation or reduce drug stability.

-

NVR may interfere with sterilization or coating processes.

-

Cleanroom-laundered wipers meeting ISO Class 4–5 standards minimize these risks.

Optics and Precision Instruments

-

Residues can alter lens coatings or affect sensor calibration.

-

Ionic contamination may cause micro-corrosion on metal components.

-

Microdenier or knitted wipers reduce fiber splitting and lower contamination risk.

Electronics and Aerospace

-

Residues and ions can cause corrosion, reduce solder joint reliability, or interfere with microcircuit performance.

-

Wipers with low NVR and controlled ion content are essential to protect sensitive components.