Maintaining cleanliness inside a cleanroom is far more than a matter of daily housekeeping — it’s about controlling invisible risks that can compromise product quality, yield, and even safety.

Every cleanroom is designed to minimize contamination, yet particles, residues, and microorganisms still find ways to enter or form within. To manage them effectively, we must first understand where they come from.

Below are the key sources of contamination that every cleanroom manager, engineer, and operator should be aware of.

Personnel — The Biggest Contamination Source

Human beings are the most unpredictable and largest contributors to cleanroom contamination. Even when properly gowned, every movement releases thousands of particles — from skin flakes to textile fibers.

Poor gowning habits, talking, or touching surfaces without care can introduce particles and oils. Perfumes, cosmetics, and even hair sprays can release volatile compounds that interfere with critical processes.

That’s why training and discipline are non-negotiable. Operators must follow gowning procedures strictly, avoid unnecessary movements, and change garments regularly. A well-trained team is the first shield against contamination.

Equipment and Tools

Cleanroom tools and production equipment are essential — yet they can easily become secondary contamination sources. Machines generate heat, vibration, and sometimes micro-abrasion, releasing metal fragments or lubricants into the air.

Even routine maintenance, if done without control, can release unseen residues or dust. Tools like screwdrivers or tweezers, when used repeatedly, can shed microscopic metal particles.

To minimize this, use cleanroom-grade, non-shedding materials and implement preventive maintenance schedules. Always clean and inspect tools before bringing them into the controlled environment.

Processes and Operations

Every manufacturing process — from wafer etching to pharmaceutical filling — has its own contamination signature. Chemical reactions, heat, and friction can all produce particulates or vapors.

Inadequate exhaust systems or improper handling of chemicals can lead to the accumulation of non-volatile residues (NVRs) on surfaces. These residues may later migrate to sensitive components.

Contamination control should be built into every operation step: choose the right materials, monitor airflow direction, and validate cleaning intervals.

Objects and Materials

Every object entering a cleanroom brings potential contaminants. Packaging materials, paper, or pallets may look harmless, but they can shed fibers or dust that become airborne.

Even cleanroom wipes or garments, if poorly manufactured, can release lint or contain ionic residues. Therefore, certified cleanroom consumables — with low particle, ion, and NVR levels — are essential.

To prevent cross-contamination, store materials in clean zones and handle them using designated carts and sealed packaging.

Common Types of Contaminants Found in Cleanrooms

| Category | Typical Contaminant | Possible Origin | Impact |

|---|---|---|---|

| Particles | Skin flakes, fibers, dust | Personnel, garments, materials | Scratches, surface defects |

| Biologicals | Bacteria, fungi, viruses | Personnel, air, humidity | Product contamination, sterility failure |

| Chemical Residues | NVRs, oils, grease | Tools, lubricants, and cleaning agents | Film buildup, corrosion |

| Ions & Metals | Sodium, zinc, copper | Equipment wear, water | Electrical shorts, yield loss |

| Films & Vapors | Condensed solvents, outgassing | Fluids, adhesives, materials | Optical or coating defects |

This table highlights how different contaminants originate from diverse sources, showing why an integrated contamination control strategy is critical.

Fluids and Airborne Contaminants

Air and fluids act as transport mediums for contamination. Any leak, condensation, or pressure imbalance can spread particles across the room in seconds.

Cooling fluids, lubricants, or cleaning solvents can degrade over time and generate unwanted residues. Likewise, HVAC systems that are not properly filtered may recirculate airborne contaminants.

Regular testing — such as airborne particle counts and LPC (Liquid Particle Counting) — helps ensure that the environment stays under control. Always maintain positive pressure and replace filters on schedule.

Cleanroom Surfaces

Walls, floors, ceilings, and workbenches can become hidden contamination reservoirs. Even smooth surfaces can trap particles through static attraction or condensation.

Improper cleaning techniques — such as wiping in circular motions or using poor-quality wipes — can redistribute contaminants instead of removing them.

The right method is simple: wipe in one direction, use folded cleanroom wipes, and replace them frequently. Always choose lint-free, compatible cleaning agents to prevent film residue.

How to Keep a Cleanroom Contaminant-Free

Keeping a cleanroom truly “clean” is a continuous process, not a one-time setup. Even the most advanced filtration and air systems cannot compensate for inconsistent cleaning practices.

To sustain long-term cleanliness, every facility should follow a validated cleaning protocol — one supported by written Standard Operating Procedures (SOPs) and frequent reviews.

Follow a Validated Cleaning Protocol

A documented cleaning procedure ensures that every operator performs cleaning tasks the same way, every time.

This includes clear instructions for cleaning frequency, direction, and motion — such as wiping from clean to dirty zones, and from top to bottom surfaces.

Validated SOPs also define which cleaning agents and disinfectants are compatible with different surfaces.

Consistency in execution is key: the same methods, tools, and timing prevent recontamination between shifts.

A cleanroom is only as clean as its cleaning process. Validation isn’t just a requirement — it’s the foundation of contamination control.

Provide Proper PPE and Cleanroom Garments

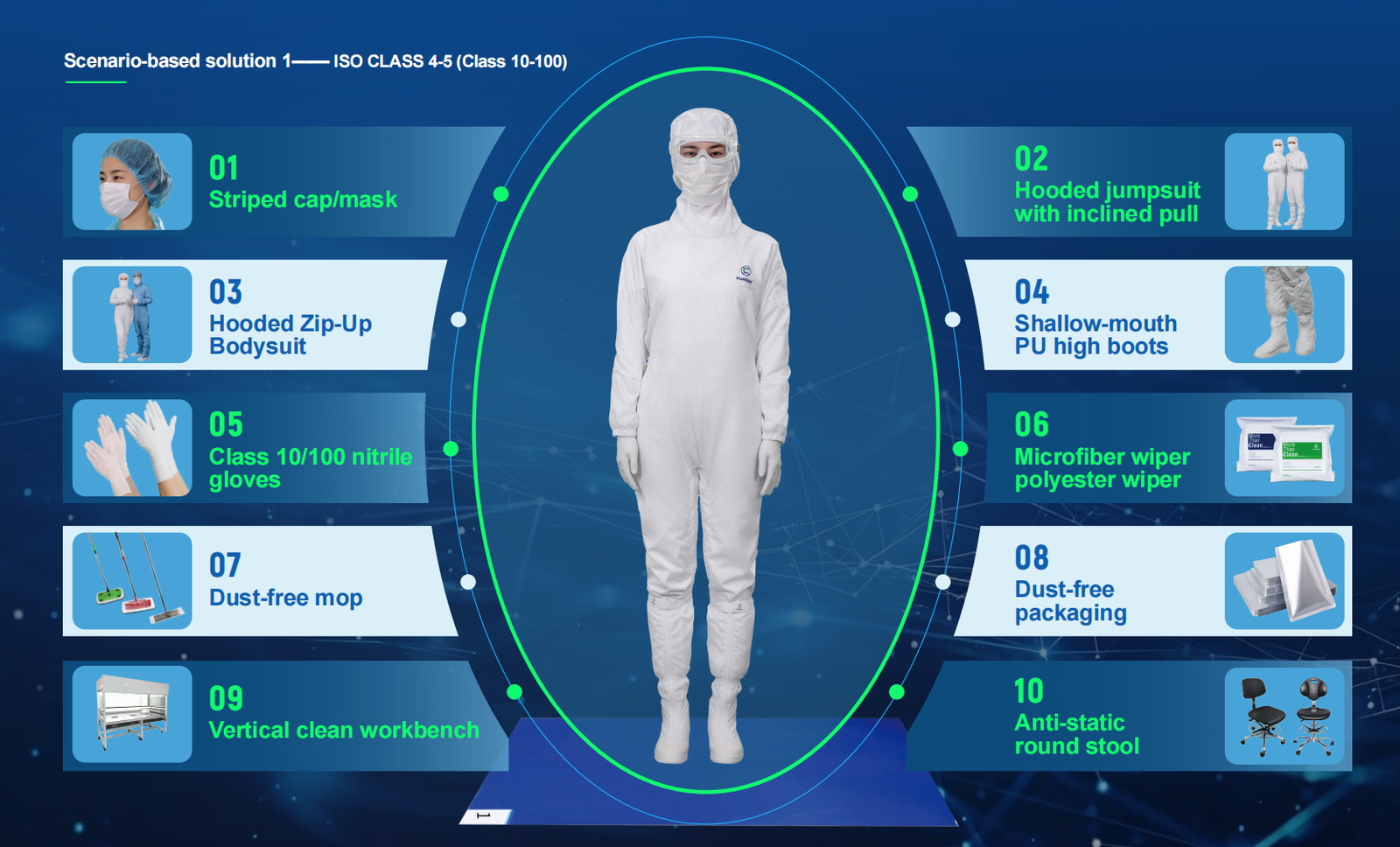

Personnel entering a cleanroom must follow strict dress codes and safety requirements to maintain a contaminant-free environment. Wearing the correct personal protective equipment (PPE) and specialized cleanroom garments forms the first line of defense against contamination.

These may include:

Cleanroom garments are essential for maintaining barrier control and reducing the shedding of skin and hair. Before entering, employees should shower thoroughly and avoid using lotions, deodorants, perfumes, or cosmetics that could introduce particles into the controlled environment.

In addition, proper hand hygiene is critical. Ensure all employees wash their hands with soap and water before donning cleanroom garments and PPE. Gloves should be worn last and removed first to maintain the integrity of the protective barrier.

Following these steps consistently helps minimize the risk of introducing particles, microbes, or other contaminants into the cleanroom, protecting both personnel and sensitive processes.

Choose and Use Qualified Cleaning Supplies

The cleanroom must be cleaned and disinfected regularly to minimize contamination risks. Only use cleaning supplies that are specifically designed for cleanroom use. Ordinary wipes, mops, or disinfectants can introduce particles or residues. Be careful when moving cleaning items in and out of the cleanroom.

Essential cleanroom cleaning supplies include:

-

Cleanroom-compatible disinfectants

-

Cleanroom vacuums

-

Non-shedding mops and wipes

For example, lint-free polyester or microfiber wipers help remove particles and NVR residues without leaving fibers behind. All consumables should come from certified suppliers, tested for particle count, ion content, and NVR levels.

To maintain reliability, rotate supplies properly, store them in sealed packaging, and replace them before visible wear appears.

Keep the System Under Review

Cleanroom conditions evolve — personnel change, new materials are introduced, and processes expand. That’s why it’s essential to audit and update your cleaning SOPs regularly.

Use environmental monitoring data (particle counts, surface testing, NVR analysis) to refine your cleaning strategy. Involve technicians in improvement discussions — their feedback often reveals small but critical contamination sources.

Continuous improvement ensures your cleanroom consistently performs at its designed class — day after day, batch after batch.

When Cleanroom Supplies Become the Problem

Ironically, the very supplies designed to control contamination can become a source of contamination themselves.

Low-quality wipes may shed lint. Gloves with excess powder can release particles. Even sticky mats, if not replaced frequently, may trap dirt on the surface rather than removing it.

The solution lies in choosing the right partner — one that provides certified cleanroom consumables tested for particles, ions, and NVRs. Remember: “No lint. High absorbency. Stable structure.” That’s what true cleanroom supplies should guarantee.

Choosing the Right Cleanroom Supplies Supplier

Selecting a trusted supplier is essential for maintaining a contamination-free cleanroom. Work with providers who offer ISO-compliant, non-linting, and ESD-safe products, including wipes, mops, and garments. Ensure they provide batch traceability, proper packaging, and clear usage instructions to prevent contamination before use.

Suppliers should also support ongoing process guidance and delivery reliability. Myesde offers a full range of cleanroom consumables, from particle-free wipes to ESD garments, designed for high-standard controlled environments.

Get in touch with us today to learn more about how we can help you manage your cleanroom right.

WhatsApp/WeChat: +86 137-7631-4975

WhatsApp/WeChat: +86 137-7631-4975