Electrostatic discharge (ESD) is an invisible but costly threat to sensitive industries such as semiconductor manufacturing, electronics assembly, aerospace, and optical engineering.

A discharge as low as 10 volts can damage advanced microchips, and even smaller charges can disrupt precision optics. While grounded workstations and ESD-safe tools are critical, they cannot protect against one major source of static—the human body.

This is why ESD control often begins with the very fabric worn by operators. ESD clothing, built from specialized ESD fabrics, is designed to minimize static buildup, dissipate charges safely, and maintain a controlled environment. Understanding how the fabric is engineered and how it becomes protective clothing is key to ensuring compliance and preventing costly failures.

Understanding ESD Fabric

Material Composition

ESD fabrics are typically woven from polyester (PES) or a polyester blend, chosen for its low particle-shedding properties and mechanical durability. To make the fabric dissipative, conductive fibers are integrated into the weave.

Common conductive fibers include:

-

Carbon-based fibers – lightweight, stable, and effective in dissipating static charges

-

Stainless steel fibers – highly durable and resilient to washing, suitable for industrial laundering

-

Silver-coated fibers – excellent conductivity with added antimicrobial benefits in certain environments

Weave Patterns

The conductive fibers can be arranged in:

-

Grid patterns (square weave) – visible fine grids across the fabric; commonly used in cleanroom garments

-

Stripe patterns – conductive yarns spaced at regular intervals, suitable for general EPA (ESD Protected Area) use

-

Full conductive weaves – higher density of conductive material for environments with stricter voltage control requirements

Electrical Properties

According to ANSI/ESD STM11.11, an ESD fabric should have a surface resistivity between 10⁵ and 10¹¹ Ω/sq to allow safe charge dissipation without creating a short circuit.

A key performance measure is charge decay time—how quickly the material can neutralize a static charge. High-quality fabrics reduce a 5,000 V charge to 500 V in less than 0.5 seconds.

Cleanroom Compatibility

For industries operating under ISO 14644 cleanroom standards, ESD fabrics must also meet particle release requirements. This means:

-

Low linting – minimal airborne fiber release

-

Chemical resistance – compatible with common cleaning agents like IPA and detergents

-

Wash durability – retaining ESD properties after repeated industrial laundering cycles

From Fabric to ESD Clothing

Types of ESD Garments

Once the fabric passes electrical and cleanliness requirements, it is cut and sewn into garments that provide full-body coverage. Common types include:

-

Lab coats – for electronics assembly lines or QA labs

-

Coveralls – full-body suits for semiconductor and cleanroom applications

-

Jacket and pants sets – flexible option for mixed-use environments

-

Full cleanroom sets – including hood, boots, and face cover for ISO Class 3–5 operations

Design Considerations

An effective ESD garment must:

-

Ensure full coverage – all non-ESD clothing underneath must be covered

-

Maintain skin contact – conductive cuffs and ankle closures create a continuous path for charge dissipation

-

Integrate with grounding systems – garments must be worn within an EPA and in contact with other grounded equipment

In cleanroom versions, garments are also designed with enclosed seams, covered zippers, and elasticated closures to minimize contamination risks.

Importance in Industry Applications

Semiconductor Manufacturing

In semiconductor fabs, even minute static charges can cause catastrophic defects. ESD garments prevent charges from building up on operators, protecting wafers, photomasks, and inspection equipment.

Example: A fab in Taiwan reported that implementing full-body ESD coveralls reduced electrostatic incidents by 30% within three months.

Electronics Assembly

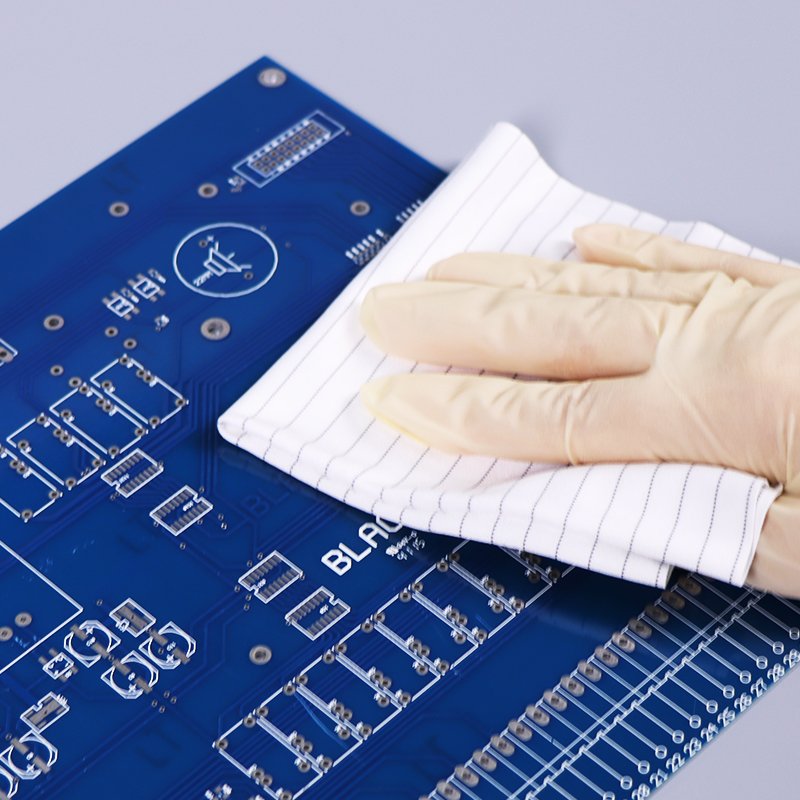

On PCB assembly lines, operators often work with exposed components. ESD jackets and smocks are a cost-effective way to reduce failures caused by accidental discharge. They also improve compliance with IEC 61340-5-1 requirements.

Aerospace and Defense

Avionics and mission-critical electronics demand extremely low failure rates. ESD garments are often used in conjunction with ESD gloves and mats to ensure component reliability during assembly and testing.

Optics and Precision Instruments

Static not only risks damaging electronics but also attracts dust to lenses and sensors. ESD garments in optical cleanrooms prevent dust accumulation that can degrade image quality.

Performance Testing

Electrical Testing

-

Surface resistivity – measured according to ANSI/ESD STM2.1 to ensure the fabric stays within the dissipative range

-

Charge decay time – ensuring charges are neutralized rapidly

Cleanroom Testing

-

LPC (Liquid Particle Count) – verifies low particle release during movement

-

NVR (Non-Volatile Residue) – ensures fabric does not leach contaminants

Durability Testing

-

Wash cycle simulation – garments tested after 50+ industrial washes to confirm long-term ESD performance

-

Solvent resistance – exposure to IPA and detergents without degradation of conductivity

Selection Guide

When choosing ESD clothing:

-

Match ISO Class and ESD requirements – Higher cleanliness levels require grid-pattern fabrics with tighter particle control

-

Check test reports – Ensure certification to relevant ANSI/ESD and ISO standards

-

Consider wash durability – Choose fabrics proven to maintain performance over expected garment life cycle

-

Fit and comfort – Operator compliance is higher when garments are breathable and ergonomically designed

Conclusion

From the first conductive fiber woven into polyester to the final stitched garment, every stage of ESD clothing production impacts safety, compliance, and product reliability. Whether in semiconductor fabs, electronics assembly plants, or optical cleanrooms, the right ESD garments protect both your products and your reputation.

Contact our technical team today for a sample set of ESD fabrics and garments, along with detailed performance test reports, to ensure your workplace meets the highest ESD protection standards.