In modern cleanrooms and controlled environments, contamination doesn’t just walk in—it rolls in. Whether it’s transport carts, material trolleys, or pallet jacks, heavy wheel traffic is one of the most persistent sources of particle intrusion, especially at entryways, airlocks, and logistics corridors. To defend against this, washable sticky mats are increasingly used as a frontline barrier.

But not all sticky mats are made to withstand wheel abrasion, pressure, and long-term performance. This article examines the design and testing of washable sticky mats for their strength, adhesion integrity, and structural durability under heavy-duty conditions.

The Challenge of Wheel-Borne Contamination

Unlike shoe-borne particles, wheel traffic often brings larger volumes of embedded dust, gravel, lubricant residue, or non-visible metal particulates. Standard peel-off mats lose their effectiveness quickly or tear under the weight of a wheel. In contrast, washable sticky mats provide:

-

A fixed, durable surface that stays in place

-

Consistent particle adhesion even after repeated rolling loads

-

The ability to be cleaned and restored in-place, eliminating waste and downtime

Why Strength Matters in Wheel-Load Zones

To resist deformation and displacement under constant rolling pressure, washable mats used in wheel traffic areas must meet specific material and structural criteria:

Key Requirements:

| Performance Trait | Reason It Matters in Wheel Zones |

|---|---|

| Tear Resistance (17 kN/m) | Prevents edge or center tearing from repeated rolling |

| Tensile Strength (4.8 MPa) | Ensures the mat does not stretch or thin over time |

| 3 mm Thickness | Provides cushioning and stability for wheels |

| Stable Edge Adhesive | Prevents mat curling, shifting, or bubbling at edges |

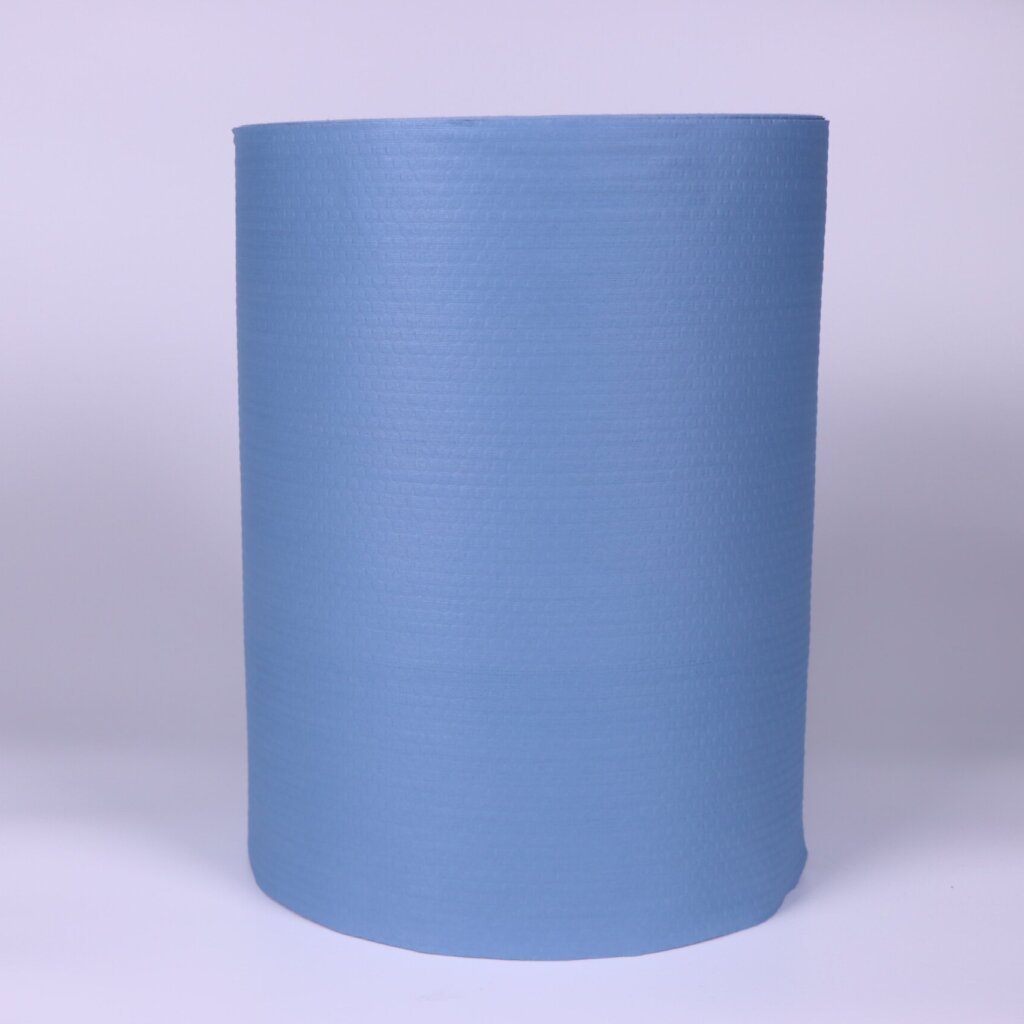

Myesde’s sticky mats are manufactured with nano-polymer silicone rubber, injection-molded and heat-cured to produce a dense, fine-grain tacky surface that remains stable even under high-frequency logistics movement.

Tack Performance Under Load

A key concern with heavy wheel usage is whether the mat can continue to capture dust after repeated compressions.

-

Myesde mats maintain nano-level stickiness after each cleaning cycle.

-

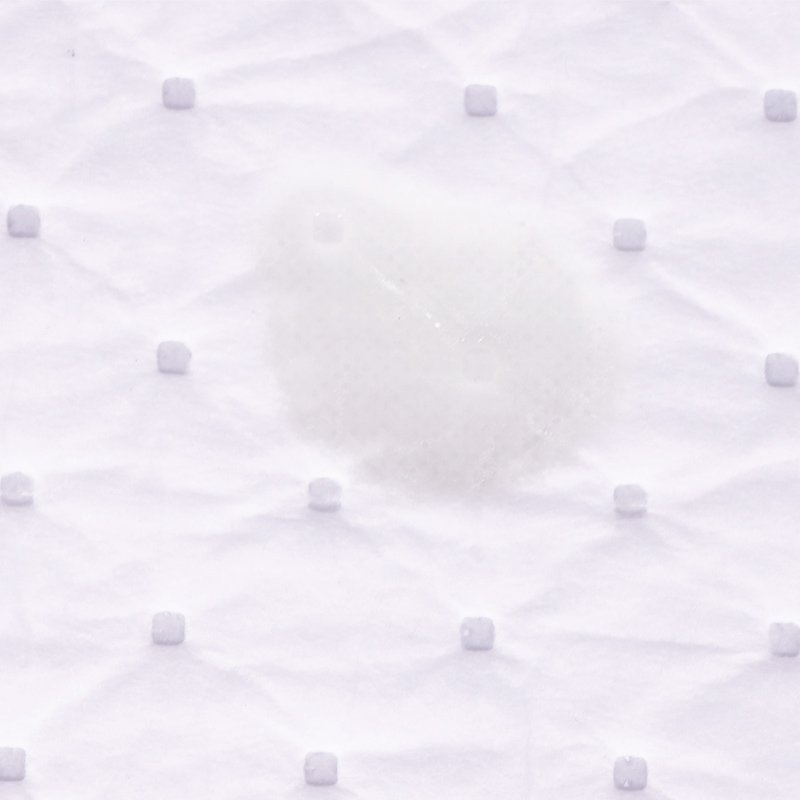

The surface texture is fine enough to trap micro-contaminants from rubber wheels without leaving marks or adhesive residue.

-

The tight molecular structure ensures the surface recovers after compression, rather than flattening out or becoming slippery.

Because the mats do not rely on pressure-sensitive adhesive but on polymer tack, their grip capacity remains consistent, ideal for cleanroom entrances with pushcarts or equipment transport.

In-Place Durability: No Movement, No Warping

Movement and deformation are common issues for low-grade mats. That’s why Myesde applies a multi-layer design:

| Layer | Material | Function |

|---|---|---|

| Top Surface | Composite Silicone Rubber (3 ± 0.2 mm) | Dust capture, tack recovery, and abrasion resistance |

| Base Adhesive | High-Adhesion PET + Release Film | Secures mat to the floor with no residual glue |

| Edge Binding | Extra-High-Tack PET (Black/Red) | Prevents lifting, curling, and corner failure |

Once installed on a flat, crack-free surface with at least 10 mm door clearance, the mat stays in position—even when heavy carts roll over it hundreds of times per day.

Maintenance Is Key to Long-Term Strength

Heavy wheel areas require frequent maintenance:

-

Spray with water or neutral detergent

-

Wipe with a cotton mop or squeegee mop

-

For oils, use IPA and a dust-free cloth

-

Let dry for 10–15 minutes before reuse

Unlike film mats, which lose layers and generate static, Myesde mats regenerate tackiness through surface cleaning alone, reducing replacement cost and particulate shedding.

Real-World Scenarios for Heavy Traffic Mats

| Location Type | Use Case |

|---|---|

| Semiconductor logistics corridors | Prevents particle migration from crates |

| Biopharma gowning carts | Captures microfibers and cellulose debris |

| Aerospace assembly staging areas | Resists aluminum dust and tooling residue |

| Warehouse-to-cleanroom interfaces | Protects clean zones from external ingress |

Because these environments demand ISO-class stability and high durability, Myesde washable mats offer a trusted solution that combines strength, safety, and environmental benefit.

Conclusion: Built for Load, Designed for Longevity

For cleanrooms experiencing regular cart movement and material transfer, washable sticky mats must be more than just sticky—they must be structurally resilient, safe, and stable. Myesde’s composite silicone rubber mats check every box:

-

High tensile and tear strength

-

Non-deforming edges

-

Consistent tack recovery

-

Simple in-place maintenance

Whether you manage a semiconductor fab, pharmaceutical site, or electronics facility, choosing the right washable mat system ensures clean floors, reduced particle counts, and long-term operational reliability.