Microfiber cleanroom wipers are prized for their superior particle entrapment, softness, and low linting. But choosing the right microfiber wiper is not as simple as picking any soft cloth.

Three critical variables shape your choice: size, weight, and edging technology. Each plays a distinct role in cleaning effectiveness, material waste, contamination risk, and compatibility with ISO cleanroom standards.

Why Microfiber for Cleanrooms?

Before diving into size and weight, let’s revisit what makes microfiber special.

Microfiber used in cleanroom wipers is a blend of polyester and polyamide (nylon). During manufacturing, fibers are split into ultra-fine strands, often thinner than 1 denier. These split fibers create a capillary network with a massive surface area, enabling the cloth to trap and retain particles, oils, and residues.

This structure:

-

Increases the absorption of solvents and particles

-

Minimizes lint generation

-

Allows gentle cleaning of sensitive surfaces like optical lenses or wafers

But even the best fiber can underperform if the wiper is too small, too thin, or poorly sealed at the edge.

Choosing the Right Size: Cleaning Area vs. Contamination Risk

Common Sizes

| Wiper Size | Typical Use Case |

|---|---|

| 4” x 4” (10 x 10 cm) | Precision cleaning (e.g., lenses, instruments) |

| 6” x 6” (15 x 15 cm) | Compact workstations, device assembly |

| 9” x 9” (23 x 23 cm) | General-purpose wiping |

| 12” x 12” (30 x 30 cm) | Large surface cleaning, benches, and tools |

Size Selection Guidelines

-

Too small, and you’ll use multiple wipes, increasing contact points and contamination risk.

-

Too large, and you may introduce folding inefficiencies or overuse.

Tip: In high-precision tasks (like CCD sensor cleaning), smaller sizes reduce physical handling, but for final wipe-downs of a chamber, larger sizes offer better coverage.

Weight: How Thickness Affects Performance

Wiper weight is typically expressed in grams per square meter (gsm). It determines:

-

Absorbency

-

Solvent holding capacity

-

Durability

Example Weight Classes

| GSM | Description | Suitable Use |

|---|---|---|

| 80–100 gsm | Lightweight | Delicate wiping, optical elements |

| 110–130 gsm | Standard weight | Balanced use: cost-effective + absorbent |

| 140–160 gsm | Heavy-duty | High solvent load, repeated wiping |

| 180+ gsm | Extra heavy | Maintenance cleaning, IPA-heavy tasks |

High-weight microfiber wipers may seem like overkill for Class 100 cleanrooms, but in areas dealing with resist residue or thin-film deposition, their absorption and mechanical strength become essential.

Tip: Use lighter-weight microfiber in ISO Class 3–4 environments, where airborne particles are strictly controlled, and heavier wipes in Class 5–7, where equipment surfaces collect more contamination.

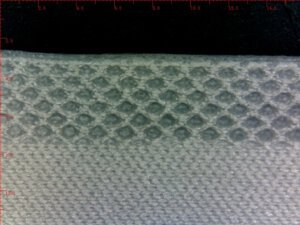

Edging: Where Contamination Often Begins

You can have the perfect size and weight, but a poorly sealed edge will shed fibers.

Common Edge Sealing Methods

| Method | Description | Pros | Cons |

| Ultrasonic | High-frequency ultrasonic vibrations melt and fuse the edge | Soft, clean, and sealed edges, minimize particle and fiber release | Higher equipment and operational costs Requires precise control to prevent edge splitting during cleaning |

| Ultrasonic Wide Edge Sealing | A wider sealed border | Meets stringent cleanliness standards | Higher production costs |

| Laser Cut | High-temperature laser to cut and seal the edges of the wiper | Clean, precise, sealed edges | Edges may become rigid |

| Hot Knife (Thermal) | Heated blade cuts and seals simultaneously | Cost-effective | Edges may exhibit a serrated or uneven appearance |

Tip: For semiconductor photolithography tools or sterile packaging areas, always choose ultrasonically or fully sealed edges to prevent particle shedding.

Application Scenarios: Choosing by Environment

Let’s translate specs into action. Here’s how to match wiper attributes to real-world cleanroom tasks:

Semiconductor Wafer Handling (ISO Class 3–4)

-

Size: 4” x 4”

-

Weight: 90–100 gsm

-

Edge: Ultrasonic

-

Reason: Extremely low particle tolerance

LCD Panel Assembly (ISO Class 5–6)

-

Size: 9” x 9”

-

Weight: 120–140 gsm

-

Edge: Laser-sealed

-

Reason: Large cleaning area, solvent use

Optical Coating Lines

-

Size: 6” x 6”

-

Weight: 100 gsm

-

Edge: Ultrasonic or Hot Knife

-

Reason: Avoid scratches, protect AR coatings

Cleanroom Maintenance Cleaning (ISO Class 7–8)

-

Size: 12” x 12”

-

Weight: 160–180 gsm

-

Edge: Hot Knife

-

Reason: Absorb IPA, remove visible residues

Packaging Matters Too

While not part of the wiper itself, the packaging ensures your microfiber stays clean until use.

-

Double-bagged vacuum packaging is essential for high-grade cleanroom wipes.

-

Labeling with batch number and class rating is key for traceability.

-

Cleanroom-compatible packaging (low particle shedding, static-free) is a must for ISO Class 4+ environments.

Conclusion

By carefully choosing the right size, weight, and edge sealing method, you can reduce risk, improve cleaning efficiency, and maintain compliance with your cleanroom’s ISO standard. Selecting the right microfiber wiper isn’t about choosing the “best” one overall—but the best fit for each task, surface, and stage of your cleanroom workflow.