Introduction

In controlled environments, such as cleanrooms, even paper must meet strict contamination control standards. Cleanroom paper is specially designed to minimize particle generation, chemical shedding, and static discharge. It plays a vital role in documentation, printing, and packaging within industries like semiconductors, biotechnology, pharmaceuticals, and aerospace.

This post explores the different types of cleanroom papers and their applications in various industries. We will also discuss how to choose the right type of paper based on your cleanroom classification.

What are Cleanroom Papers?

Cleanroom papers are manufactured from low-particulate cellulose or synthetic fibers. It undergoes special processing to reduce lint, ionic contamination, and outgassing.

Common features include:

-

Low particle generation

-

ESD (electrostatic discharge) control

-

Chemical resistance

-

Compatibility with ISO Class 3–7 cleanrooms

It is ideal for environments where standard office paper could introduce unacceptable contamination risks.

Types of Cleanroom Papers

1. Cellulose Cleanroom Papers

-

Made from high-grade cellulose pulp

-

Typically used in Class 100-1000 cleanrooms

-

Low-linting and durable

-

Often used for note-taking and printing documents in cleanrooms

Keywords: cellulose cleanroom papers, low-lint paper

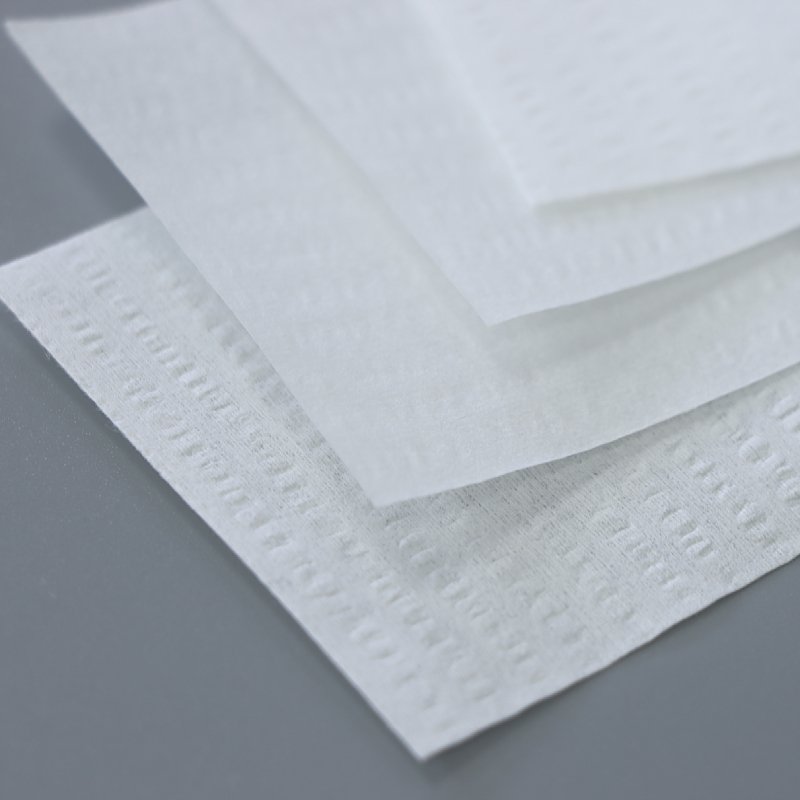

2. Synthetic Fiber Cleanroom Papers

-

Blends of polyester and cellulose or full synthetic polymer

-

Designed for highly sensitive cleanrooms (Class 10 and above)

-

Provides better chemical resistance and durability

-

Often used in pharmaceutical and biotech settings

Keywords: synthetic cleanroom papers, chemical-resistant paper

3. ESD-Safe Cleanroom Papers

-

Engineered to prevent electrostatic discharge

-

Often includes carbon coating or ESD-safe polymer additives

-

Ideal for use in electronics and semiconductor industries

Keywords: ESD cleanroom papers, anti-static cleanroom papers

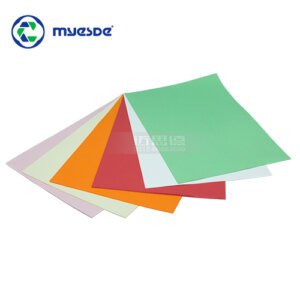

4. Colored Cleanroom Paper

-

Available in blue, pink, green, and yellow

-

Helps in color-coding and document classification

-

Maintains all cleanroom properties of white paper

Keywords: colored cleanroom papers, cleanroom document paper

Applications of Cleanroom Papers

1. Note-Taking and Logbooks

Used by cleanroom personnel for:

-

Recording experiments and protocols

-

Maintaining cleanroom logs

-

Documenting maintenance schedules

2. Printing and Documentation

Compatible with laser and inkjet printers:

-

Printing standard operating procedures (SOPs)

-

Creating batch records

-

Generating equipment checklists

3. Cleanroom Packaging

Some synthetic cleanroom papers are used for:

-

Wrapping instruments

-

Lining cleanroom trays

-

Temporary protection of delicate components

4. Labeling and Tags

ESD-safe and synthetic papers are used for:

-

Asset tagging

-

Process labeling

-

Sample ID and documentation

Keywords: cleanroom documentation, cleanroom packaging, cleanroom labeling paper

How to Choose the Right Cleanroom Paper

When selecting cleanroom papers, consider:

1. Cleanroom Classification

-

For ISO Class 3–5, use synthetic or ESD-safe paper

-

For Class 6–7, cellulose-based paper may suffice

2. Application Needs

-

Choose ESD-safe paper for electronics and circuit board environments

-

Choose colored paper for organization and labeling

3. Durability and Compatibility

-

Ensure compatibility with printers, binders, and archiving systems

OEM & ODM Services

We offer OEM and ODM cleanroom papers solutions, including:

-

Custom sizing and packaging

-

Private labeling

-

Color and ESD treatment options

-

Bulk supply for global distribution

Conclusion

Cleanroom paper is essential for documentation, labeling, and packaging in controlled environments. Choosing the right type of paper helps reduce contamination risks, supports regulatory compliance, and improves cleanroom workflow efficiency.

Explore our wide selection of cellulose, synthetic, ESD-safe, and colored cleanroom papers to find the best fit for your facility.

Looking for reliable cleanroom papers suppliers with OEM & ODM capabilities?