Jiangsu Province,China

24/7 Customer Service

WhatsAPP/Wechat

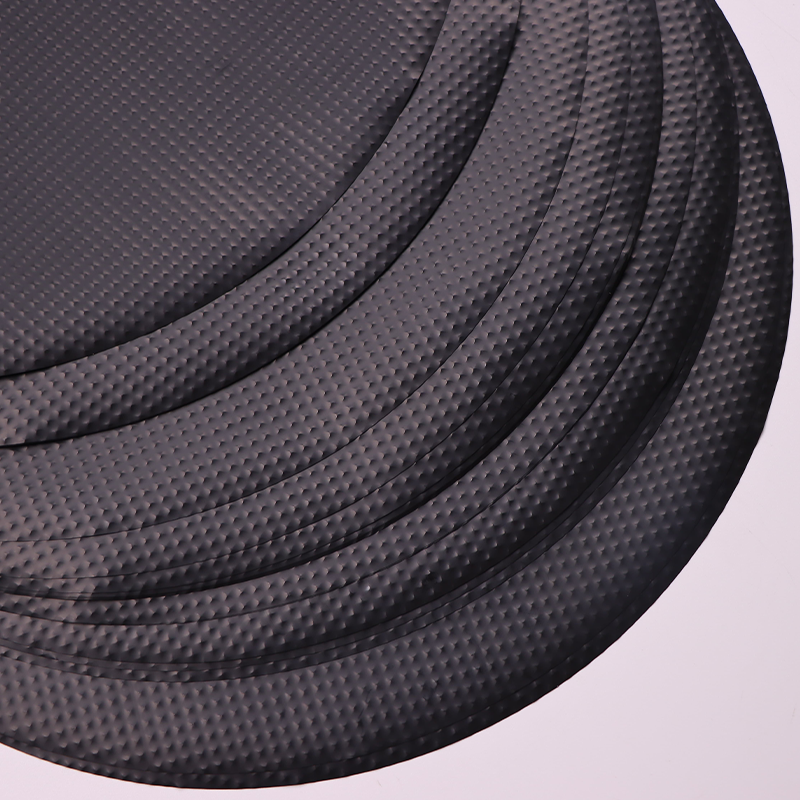

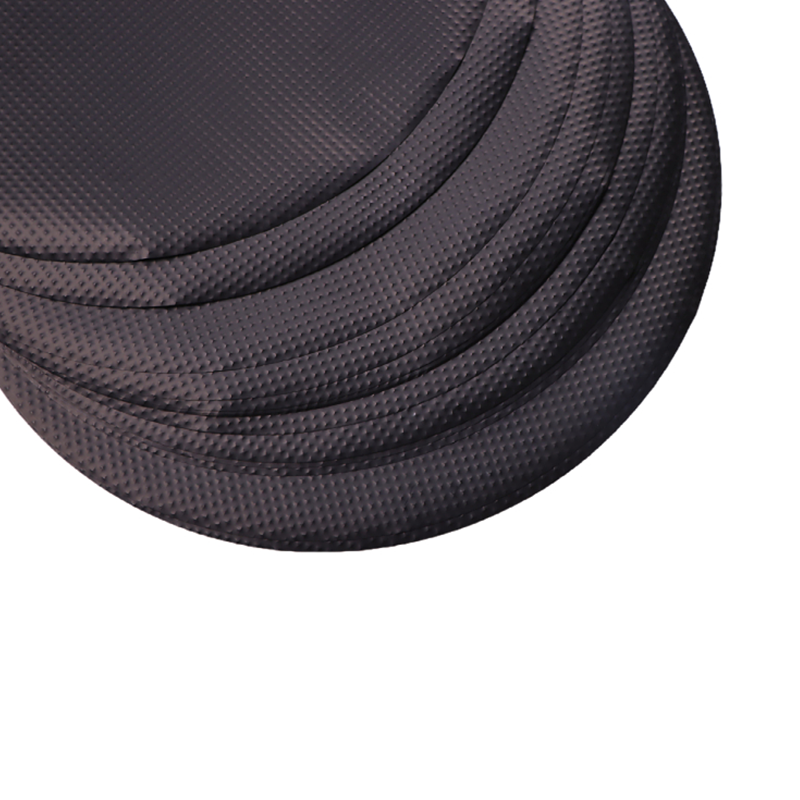

A wafer spacer is a crucial component used in semiconductor manufacturing, particularly in the fabrication and handling of wafers during various processes. These spacers help maintain the proper spacing between wafers, ensuring safe storage, transport, and processing while minimizing the risk of damage.

Did We Answer Your Question?

Suzhou Myesde Ultra Clean Technology Co.,LTD

Building 5, Wenyuan Industrial Park, Dongwu South Road, Wuzhong District,

Suzhou, China

Tel / WhatsApp / Wechat: +86-137-7631-4975

E-mail: info@cldzcl.com

Copyright © 2025. Suzhou Myesde Ultra Clean Technology Co.,LTD

We’re ready to provide fast, knowledgeable support.