Cleanrooms are designed to maintain a controlled environment, but even the smallest oversight in cleaning can result in contamination, which may lead to costly errors or downtime. Whether you’re working in the pharmaceutical, semiconductor, or biotech industries, maintaining a spotless cleanroom is vital for your operation’s success. Unfortunately, many businesses make mistakes in their cleaning protocols, often without even realizing it. But don’t worry! In this article, I’ll walk you through the 5 common cleanroom cleaning mistakes and provide simple, actionable fixes to ensure your cleanroom remains as contaminant-free as possible.

1. Using the Wrong Type of Wiper

The Mistake:

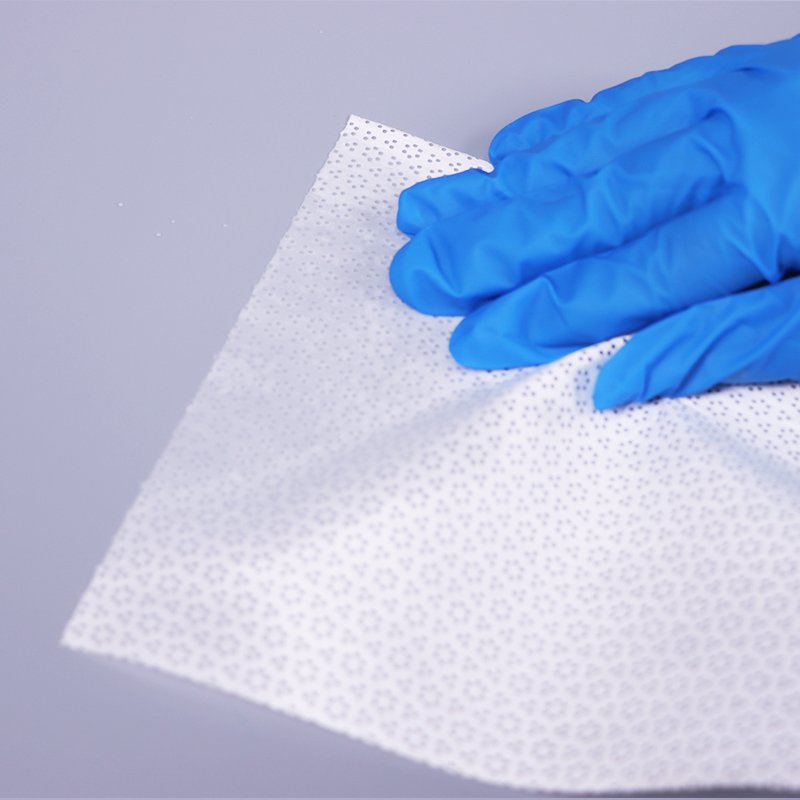

One of the most common mistakes in cleanroom maintenance is using the wrong type of cleaning wipes or cloths. Some businesses rely on regular cleaning towels or disposable wipes that aren’t designed for cleanroom use. These often shed particles, which can contaminate the environment and compromise product quality. If you’re using cotton, paper towels, or regular microfiber cloths in your cleanroom, you’re likely introducing contaminants that could negatively impact your operations.

How to Fix It:

To avoid this, always use cleanroom-specific wipers like polyester cleanroom wipers. These wipers are designed to shed fewer fibers and generate minimal particles, making them perfect for maintaining a sterile environment. Polyester wipers are highly absorbent, non-abrasive, and designed to trap dirt and contaminants without releasing them back into the air or onto surfaces. They are also more durable, reducing the need for frequent replacements.

Action Tip: When selecting wipers, make sure to choose those rated for your cleanroom class (ISO 5, ISO 7, etc.). The tighter the weave, the better the particle control.

2. Not Following the Correct Cleaning Procedure

The Mistake:

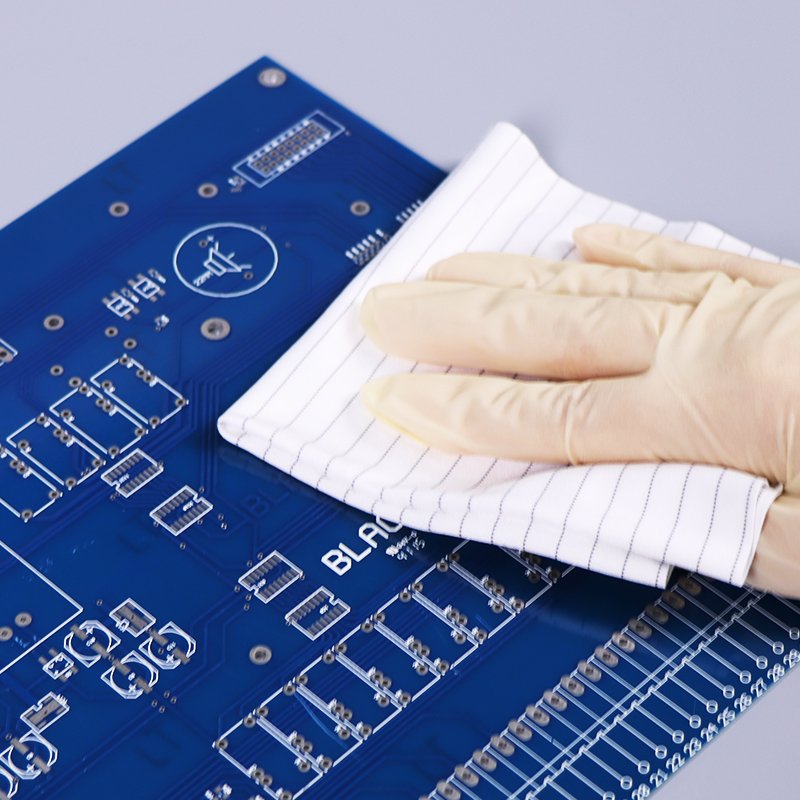

Cleanroom cleaning is not just about wiping down surfaces. Many facilities make the mistake of cleaning in a haphazard or inefficient way. Cleaning without a systematic approach can lead to cross-contamination and missed areas. In some cases, workers might also skip steps like damp-wiping or fail to use approved cleaning agents, which further increases the risk of contamination.

How to Fix It:

Implement a standard operating procedure (SOP) for cleanroom cleaning, which includes clear instructions on how to clean different areas and surfaces. For example, when wiping down equipment, always start from the cleanest areas and move toward the dirtiest to avoid re-contaminating areas you’ve already cleaned. Use the wipe-on-wipe-off technique, where one wipe is used to apply cleaning solution, and a second clean wipe is used to remove contaminants. Also, never reuse cleaning wipes to avoid cross-contamination.

Action Tip: Regularly review and train staff on your cleanroom SOPs to ensure they follow best practices.

3. Overlooking Equipment and Surfaces

The Mistake:

It’s easy to focus on obvious areas like countertops and floors, but equipment and hard-to-reach surfaces can easily be overlooked. Sensitive equipment, tools, and even ceiling vents can harbor dust and contaminants that can compromise the entire cleanroom environment. Ignoring these areas can lead to contamination that is difficult to trace back to its source.

How to Fix It:

Ensure that every corner of your cleanroom is addressed, including equipment, shelves, overheads, and even the flooring. Use cleanroom-compatible cleaning tools like specially designed brushes or microfiber mops to clean small spaces and equipment surfaces. Don’t forget to clean the air vents, HVAC systems, and any exposed pipes, as these areas can accumulate dust and particles over time.

Action Tip: Create a comprehensive cleaning checklist that includes every piece of equipment, surface, and fixture in your cleanroom. Assign specific team members to check off each area regularly.

4. Improper Use of Cleaning Solutions

The Mistake:

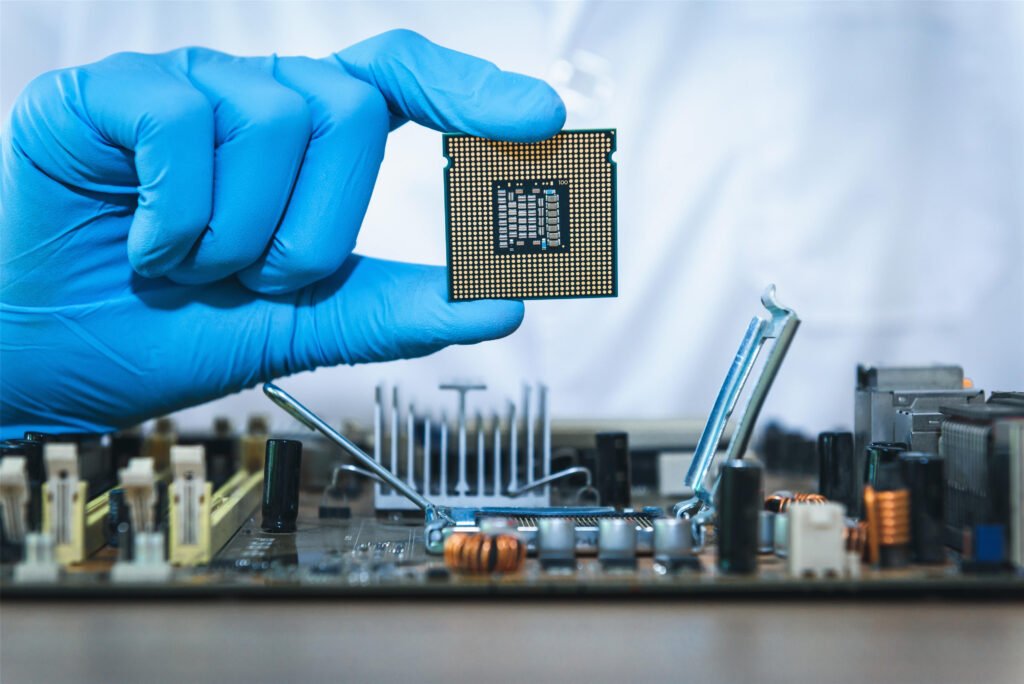

Another mistake many businesses make is incorrectly applying cleaning solutions or using harsh chemicals that can leave residues or damage equipment. The wrong cleaning solution can interfere with the operation of sensitive electronics, leave harmful residues on surfaces, or even cause an adverse reaction with products in the cleanroom.

How to Fix It:

Use cleanroom-approved cleaning solutions that are specifically formulated for the type of surfaces and equipment in your environment. For example, when cleaning electronics or sensitive machinery, avoid solvent-based cleaners that may damage them. Additionally, always dilute concentrated cleaning solutions according to the manufacturer’s guidelines, and be sure to dry wipe or air dry surfaces after applying any wet solutions.

Action Tip: Have a designated storage area for your cleaning solutions and ensure that they are clearly labeled to avoid accidental misuse.

5. Failing to Maintain Cleanroom Tools and Equipment

The Mistake:

Even if you’re using the right cleaning materials, poor maintenance of cleanroom tools—such as wipers, mops, or brushes—can lead to contamination. Dirty equipment can harbor bacteria, dust, and other particles that undo all your hard work. If you’re not properly washing, disinfecting, or storing cleaning tools, they may become a source of contamination themselves.

How to Fix It:

Regularly inspect and maintain your cleanroom tools. After each use, wash and disinfect your wipers and cleaning cloths. Store tools in a designated, contamination-free area, away from dust or other contaminants. Also, ensure that your tools are properly dried before reuse to avoid introducing moisture into the cleanroom environment.

Action Tip: Set up a routine maintenance schedule to inspect and sanitize cleaning tools regularly, ideally after each use.

Conclusion

Maintaining a cleanroom is an ongoing effort that requires attention to detail and consistent adherence to best practices. By avoiding these common cleaning mistakes, you’ll ensure that your cleanroom remains compliant, efficient, and free of contaminants.

Need high-quality polyester cleanroom wipers or other cleaning tools?

Contact us today to learn more about our top-rated products, tailored to your cleanroom’s specific needs. We offer solutions that help you maintain a sterile environment while improving overall operational efficiency.

-3.jpg)