What Is a Cleanroom and Why Does It Matter?

In industries where even the smallest particle or contamination can cause major issues, such as semiconductor manufacturing, pharmaceuticals, and biotechnology, cleanrooms are critical. A cleanroom is a highly controlled environment designed to maintain extremely low levels of particulates, such as dust, airborne microbes, and vapors. But creating and maintaining such environments isn’t just about air filtration and strict regulations. Cleanroom supplies, from wipes to apparel, play a pivotal role in contamination control. These supplies ensure that both the workers and the equipment remain free from contaminants that could jeopardize sensitive processes.

Cleanroom Design and Setup: Laying the Foundation for Contamination Control

Designing a cleanroom is no small task. It requires careful planning to create a space that meets the specific needs of the industry it serves.

Critical design elements include:

- HEPA or ULPA filtration systems

- Temperature and humidity control

- Pressure differentials and airlock systems

- Zoning and personnel/material flow protocols

However, no matter how sophisticated the design, maintaining cleanliness requires more than just physical space management—it also requires the right tools. Cleanroom supplies such as wipes, apparel, gloves, and masks all contribute to keeping the space free from contaminants. Choosing the correct cleaning supplies is just as important as choosing the right air filtration system, as improper products can introduce particles or chemicals into the controlled environment.

Cleanroom Classification Standards: Understanding ISO 14644-1 and US FED STD 209E

Cleanrooms are classified by the numbers of particles in a given volume of air. The FED STD 209E counts the number of particles per cubic foot. The ISO 14644-1 counts the number of particles per cubic meter.

US FED STD 209E Cleanroom Standards | Cleanroom Classifications

| Class | >0.1 um | >0.2 um | >0.3 um | >0.5 um | >5 um | ISO equivalent |

|---|---|---|---|---|---|---|

| 1 | 35 | 7 | 3 | 1 | ISO3 | |

| 10 | 350 | 75 | 30 | 10 | ISO4 | |

| 100 | 100 | ISO5 | ||||

| 1000 | 1000 | 7 | ISO6 | |||

| 10,000 | 10,000 | 70 | ISO7 | |||

| 100,000 | 100,000 | 700 | ISO8 |

ISO 14644-1 Cleanroom Classification Standards

| Class | >0.1 um | >0.2 um | >0.3 um | >0.5 um | >1 um | >5 um | FED STD 209E equivalent |

|---|---|---|---|---|---|---|---|

| ISO 1 | 10 | 2 | |||||

| ISO 2 | 100 | 24 | 10 | 4 | |||

| ISO 3 | 1,000 | 237 | 102 | 35 | 8 | Class 1 | |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | Class 10 | |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 | Class 100 |

| ISO 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 | Class 1,000 |

| ISO 7 | 352,000 | 83,200 | 2,930 | Class 10,000 | |||

| ISO 8 | 3,520,000 | 832,000 | 29,300 | Class 100,000 | |||

| ISO 9 | 35,200,000 | 8,320,000 | 293,000 | Room Air |

Key Differences:

-

ISO 14644-1 focuses on particle count per cubic meter, while US FED STD 209E uses cubic feet.

-

ISO standard remains in use today, while US FED STD 209E was officially retired in 2001 but is still referenced in legacy systems.

Wipes used in ISO Class 1 environments need to be ultra-lint-free and have minimal particle release, which is why high-quality, presaturated wipes are often preferred. These products help maintain the required cleanliness level while minimizing the risk of contamination.

HEPA vs. ULPA Filters: Choosing the Right Filter for Your Cleanroom

HEPA (High-Efficiency Particulate Air) and ULPA (Ultra-Low Penetration Air) filters are two of the most commonly used filtration systems in cleanrooms. HEPA filters are designed to remove 99.97% of particles as small as 0.3 microns, while ULPA filters are even more efficient, removing 99.999% of particles down to 0.12 microns.

| Filter Type | Efficiency | Particle Size Removed | Semiconductor Applications |

| HEPA | 99.97% | ≥0.3 µm | ISO 5–7 Cleanrooms (Back-end Processing) |

| ULPA | 100.00% | ≥0.12 µm | ISO 1–4 Cleanrooms (Wafer Fabrication) |

Case Study: EUV Lithography and Air Filtration

Extreme Ultraviolet (EUV) Lithography, which operates at 13.5 nm wavelengths, requires ISO 3 cleanrooms. Any contamination could scatter light and disrupt the lithography process. This is why EUV facilities exclusively use ULPA filters with a capture efficiency of 99.9995% for particles ≥0.12 µm.

The filter you choose depends on the cleanroom’s classification and the sensitivity of the process being carried out. However, it’s essential to remember that while filters control airborne particles, they don’t address surface contamination. Cleanroom wipes, used in conjunction with HEPA or ULPA filters, help clean surfaces, machinery, and even workers, ensuring all potential contamination sources are covered.

Cleanroom Sterile and ESD: Special Considerations for Sensitive Environments

Sterility and Electrostatic Discharge (ESD) are two critical factors in many cleanroom environments, especially in semiconductor manufacturing and biotechnology.

-

Sterility in Cleanrooms: Semiconductor cleanrooms are often sterile to prevent molecular contamination. Wipes used in these environments must be non-shedding, made of 100% continuous filament polyester, and laser-sealed to prevent fiber loss.

-

ESD (Electrostatic Discharge) Protection:

-

The charge generated by walking on a standard floor can exceed 3,000V, enough to destroy sensitive semiconductor devices.

-

ESD-safe cleanroom wipes have surface resistivity <10⁹ Ω/sq, ensuring charge dissipation without affecting delicate electronics.

-

Sterile wipes, for instance, are specifically manufactured to avoid introducing any contaminants. Meanwhile, ESD-safe gloves and apparel are essential in maintaining a static-free environment. Properly selecting these supplies ensures that cleanrooms meet industry-specific needs while maintaining contamination control.

ESD Environment Considerations for Cleanrooms: Protecting Your Sensitive Equipment

ESD, or Electrostatic Discharge, can cause irreparable damage to sensitive equipment and components, especially in semiconductor manufacturing. A cleanroom designed to be ESD-safe requires not just appropriate flooring and grounding systems but also ESD-safe wipes and gloves.

| Glove Type | Best For | Limitations |

|---|---|---|

| Nitrile | Chemical resistance, low particulates | More expensive than latex |

| Latex | High dexterity, low cost | Not suitable for sensitive processes |

Nitrile gloves are often preferred in sterile environments because they are non-latex, making them suitable for workers with latex allergies. Nitrile also offers superior resistance to chemicals and punctures. On the other hand, latex gloves can be more comfortable and flexible for certain tasks, though they need to be used with care in sensitive environments.

Fingercots, often used with gloves, protect the tips of the fingers while allowing more dexterity and comfort. These gloves and fingercots, combined with other cleanroom apparel, form a protective barrier against contamination, ensuring that workers do not inadvertently introduce particles into the cleanroom environment.

Beyond gloves and fingercots, cleanrooms also require other protective gear, such as gowns, masks, and eye protection. These items create a barrier between the worker and the cleanroom environment, preventing the introduction of particles, oils, and other contaminants.

Choosing the right PPE ensures that workers can perform their duties safely while minimizing the risk of contamination. High-quality cleanroom apparel, like head coverings, face masks, and shoe covers, prevents particles from being shed by workers and helps maintain the required air quality and cleanliness levels.

Cleanroom Supplies: The Heart of Cleanroom Maintenance

Example: Removing Residues from Silicon Wafers

A 12-inch wafer fab requires IPA-saturated polyester wipes for organic residue removal before photolithography.

While design and setup are critical, ongoing maintenance relies heavily on high-quality cleanroom supplies. These supplies—such as cleanroom wipes, cleanroom apparel, and cleanroom paper—are essential for keeping the cleanroom free from contamination.

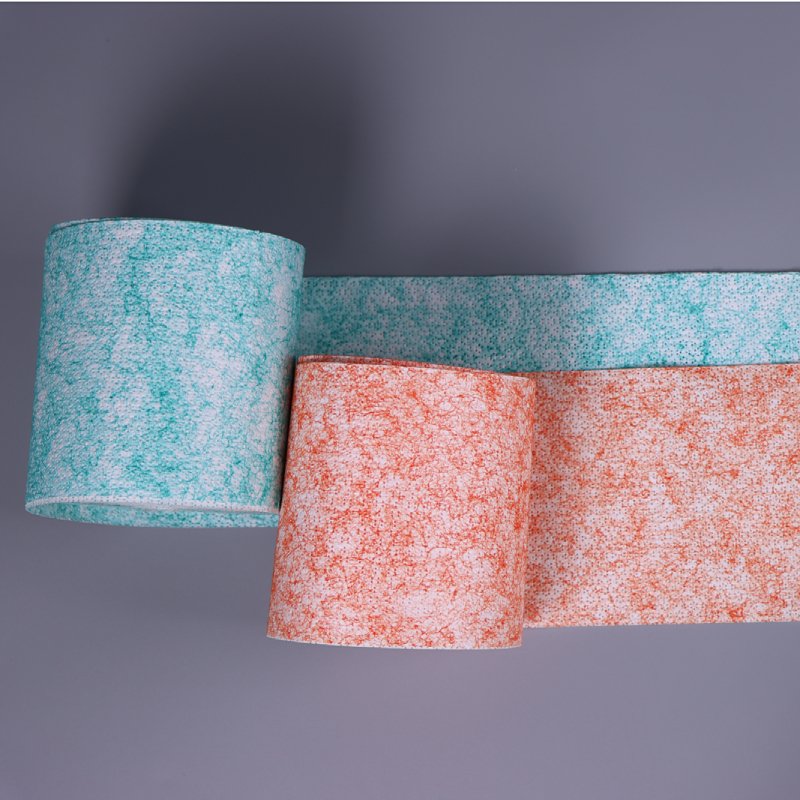

Cleanroom Wipes: Wipes made from lint-free materials like polyester or poly-cellulose are designed to remove particles without shedding fibers. Presaturated wipes are also commonly used in sensitive environments as they ensure precise cleaning and reduce the risk of contamination from external sources.

Cleanroom Apparel: Cleanroom clothing is designed to prevent contamination from human particles. It includes items like coveralls, hoods, gloves, and shoe covers. Choosing the right apparel is crucial for maintaining the integrity of the cleanroom.

Cleanroom Paper: Used for everything from documenting procedures to cleaning equipment, cleanroom paper is manufactured to meet stringent cleanliness standards. It’s important to choose paper that is compatible with the cleanroom’s classification and contamination control needs.

If you’re looking for high-quality cleanroom supplies tailored to your specific needs, contact Myesde Wiper today. We offer a wide range of cleanroom supplies to meet the highest standards of cleanliness and contamination control. Let us help you maintain a pristine environment for your sensitive processes.

📞 Looking for the best cleanroom supplies for your industry? Contact Myesde today!

FAQs About Cleanroom

Q: What is the difference between ISO 14644-1 and US FED STD 209E Cleanroom Classification Standards?

A: ISO 14644-1 defines cleanliness based on particle count per cubic meter, while US FED STD 209E uses cubic feet. Although US FED STD 209E was officially withdrawn in 2001, many industries still reference it for legacy systems.

Q: What is the purpose of using HEPA and ULPA filters in cleanrooms?

A: HEPA filters remove at least 99.97% of particles ≥0.3 µm, while ULPA filters capture 99.999% of particles ≥0.12 µm, ensuring strict contamination control in various cleanroom environments.

Q: Why is ESD control important in cleanrooms?

A: Electrostatic discharge (ESD) can damage sensitive electronics and attract contaminants. Using ESD-safe wipes, flooring, and apparel prevents static buildup and protects cleanroom integrity.

Q: What types of cleanroom gloves should be used for different applications?

A: Nitrile gloves provide chemical resistance and low particle shedding, while latex gloves offer superior dexterity but may cause allergic reactions. Selection depends on cleanliness requirements and chemical exposure risks.

Q: How do cleanroom wipes differ from regular wipes?

A: Cleanroom wipes are lint-free, low-particle, and made from non-contaminating materials such as 100% polyester or poly-cellulose blends. They are designed to prevent fiber shedding and meet stringent ISO cleanliness standards.

Q: What are the advantages of presaturated cleanroom wipes?

A: Presaturated wipes (typically with 70% Isopropyl Alcohol (IPA) and 30% deionized water) provide consistent chemical application, eliminating the risk of contamination from improperly mixed cleaning solutions.

Q: What is the significance of cleanroom air pressure and airflow control?

A: Cleanrooms use positive pressure to keep contaminants out in controlled environments (e.g., pharmaceutical manufacturing) and negative pressure for hazardous material handling (e.g., biosafety labs).

Q: How do I select the right size of cleanroom wipes for my application?

A: Choose 6”x6” wipes for precision cleaning, 9”x9” wipes for general equipment maintenance, and 12”x12” wipes for large surface cleaning. Larger wipes increase efficiency, while smaller wipes offer precision.

Q: What materials are cleanroom garments made from?

A: Cleanroom apparel is typically made from polyester with carbon grid for ESD control or microporous film for sterile environments to prevent particle shedding and contamination.

Q: Where can I find high-quality cleanroom supplies that meet industry standards?

A: Myesde provides ISO-certified cleanroom wipes, gloves, apparel, and ESD control products designed for various cleanroom environments. Contact us today for expert consultation and high-performance solutions!